Repetitive tasks are poor in Added Value

When repetitive tasks are automated, the staff working in Procurement have time freed to focus on analysis and decisions that can add value, unlike tracking purchase orders.

In your organisation, what percentage of purchase orders raised in Procurement must be changed before the items are received? Typically, this will require repetitive tasks in purchasing applications and/or spreadsheets to update the affected parameters. Then, the supplier is sent a revised purchase order via the system or through email.

But this is not obtaining added value from Procurement. Are the problems requiring repetitive correction activities caused by having inadequate resources and time applied at the early stages of Procurement? As in many endeavours, effort expended at the planning stages typically result in a more successful outcome; and less time spent in fixing operational problems.

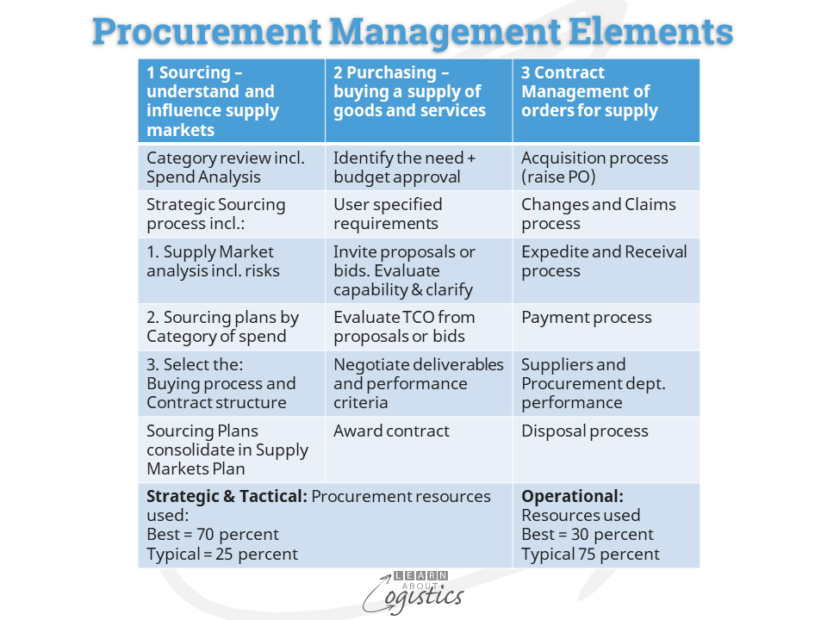

The table below illustrates the main activities within the three stages of Procurement: Strategic sourcing, Tactical purchasing and Operational Contract management.

The bottom cells of the table provide critical information. The UK based Procurement consultants PMMMS has identified that resources and time used in Strategic and Tactical activities are typically well below what can be considered as best practice. Conversely, the resources used for Operational tasks are typically much higher than should be expected.

The cause is historical – the old purchasing department was considered a clerical operation. It was also used to employ the ‘walking wounded’, production employees who required recuperation from an injury before re-joining manufacturing. The need for investment in people development and IT applications was not a high priority.

Investment in applications for Procurement

As perceptions by senior management concerning the role of Procurement have begun to change, so investment in specific IT applications that interface with the corporate ERP system has occurred. However, developing (and selling) a suite of integrated applications that address the specific needs of Operational Contract Management will take time. The IT research firm Gartner considers that it will be out to 2025 before comprehensive ‘Purchase to Pay’ software suites are available that address the contract lifecycle with automation.

The implementation of a ‘Purchase to Pay’ suite may be justified through the reduction in people engaged in repetitive tasks. But, it will be more difficult to justify the implementation of software that enables improved strategic and tactical Procurement decisions.

As organisations employ people for the more strategic requirements, so there will be an expectation that the necessary tools are available (most likely on a subscription basis). However, Gartner considers that it will be 5-10 years before applications are available for what are considered to be three core Procurement applications: Category Management and analytics; B2B supply network intelligence and Supplier (and supply markets) risk analysis. This indicates that transferring higher level human capabilities into an IT application is a challenging project that requires the application of machine learning and other AI techniques, which may need to be developed.

Within a Category Management application, an essential need is for Spend Analysis. That is, to gather (potentially from multiple systems), the accounting transactions with suppliers, then clean and sort the data into a structure that is meaningful and useful for Procurement professionals. This is a complex software design task due to the common situation with suppliers:

- Suppliers can trade under multiple divisions and businesses, although ultimately owned or controlled by one entity

- The billing address and ‘ship from’ address for a supplier may well differ, but Procurement needs to identify the reliance on particular supplier locations

- A supplier’s name can be entered differently in the buying organisation’s accounts payable files, as orders are raised. For example, Ford Motor Company and Ford Australia

- There are multiple general ledger and cost centre names

- Categories and standard industry (SIC) codes may be used in one part of the organisation, but not others

- Descriptions of the product or service can vary, depending on the user

Supply Network intelligence is a necessary requirement for an effective Supply Markets plan. Examples of the intelligence required are noted in a previous blog so, for the intelligence to be of use to Procurement is a challenge. In the past we could rely on traditional information sources via libraries, exhibitions and conferences, but that is changing as ‘working from home’ reduces the ability to make random connections that provide useful links. Instead, it is likely that unstructured data will be collected from multiple sources and analysed using AI to build intelligence about supply markets and suppliers.

The supply challenges faced by many businesses through 2020 may hasten the development of Supplier Risk Management analysis. Even so, addressing the different types of risk in global supply markets is not a simple task, as discussed in a previous blog.

Procurement’s level of influence

The challenges in developing strategic and tactical software applications means that subscription rates to use the applications as a Software as a Service (SaaS) will be high. The justification within an organisation to take up a subscription that does not have a measurable return on investment will depend on the level of influence that Procurement professionals can generate with other executives. Influence will be identified through:

- The senior Procurement executive participates in corporate discussions concerning corporate strategy, profitability and product development. They are a member of the executive board or report directly to a board member

- Procurement is seen as the corporate interface between the organisation and its supply markets and is the custodian of intelligence concerning supply markets and suppliers

- Procurement establishes the policy concerning spend with suppliers and is a core part of decisions concerning major purchases. It has the authority to commit and pay funds for purchases, but can delegate authority to accredited purchasing units (APUs) within the organisation

- Procurement enables cross-function teams to oversea the quality of procurement processes in the organisation and to identify improvements

For Procurement, the future is digital, but it will not be a ‘big bang’. Instead applications specifically designed for Procurement will be progressively incorporated over the next ten or more years, commencing with automating the Purchase to Pay process.