The challenge of words

At a recent aerospace conference, the CEO of a major company stated that he expected the sector to be affected by supply chain issues until the end of 2024. Of greater concern for supply chain professionals, he stated that “we have to resolve the supply chain issues and the surprises associated with them; and we have to resolve them once and for all” (emphasis by LaL).

But is this objective achievable? Unfortunately, the answer is NO. That he says the current supply chain issues will be addressed by the end of 2024 indicates that actions are happening for this disruption. But what about the next disruption and the disruption after that? It is unlikely that the causes will be the same as the current disruption. Does this means that a supply chains group must be in a continuously reactive mode, in response to their CEO directives to “fix the problem”?

But why would a CEO believe that supply chain issues in their business can be resolved ‘once and for all’? Is it because their perceptions of what is possible are driven by the terminology used? There are at least three terms which are often used and provide an incorrect perception of supply chains.

Frequent use of the term Supply Chain Management provides a perception for a CEO and other senior managers (who are unlikely to have a deep knowledge of supply chains) that supply chains can be managed. Therefore managers can resolve “…issues and the surprises associated with them…once and for all”.

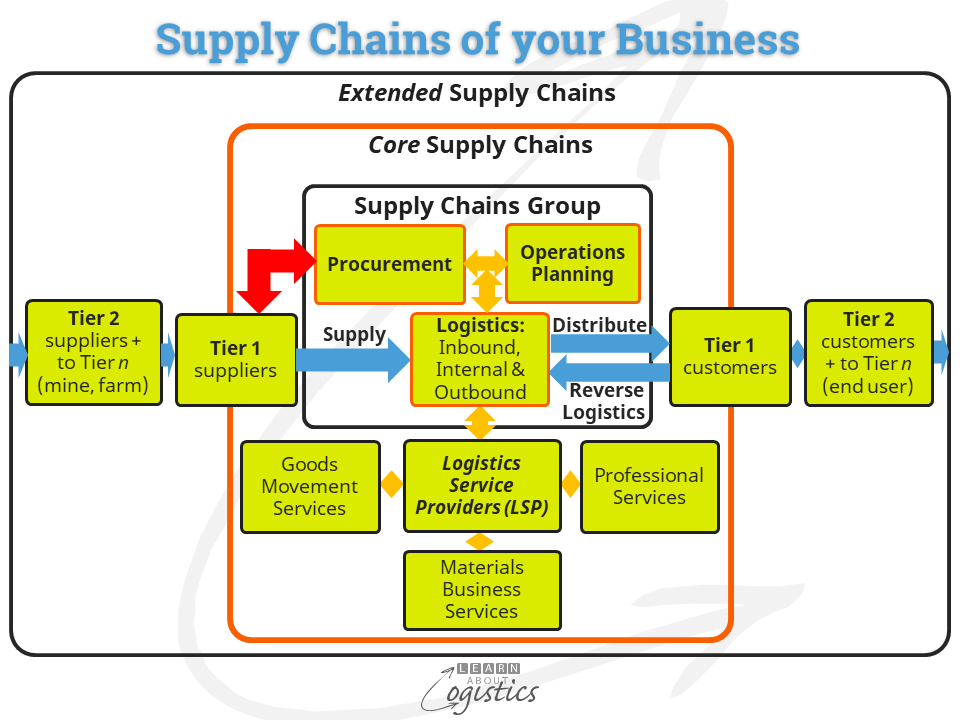

But supply chain professional know that all the supply chains for a business cannot be managed. At best, the relationships and risks can be managed between an organisation and its Tier 1 suppliers and customers – the Core supply chains. For the Extended supply chains, located at Nodes and Links in the outer network of suppliers and customers, the objective must be to comprehensively understand the demand and supply markets. This enables the organisation to be aware of and better able to foresee and respond to events.

An additional perception caused by terminology is that of using the term supply chain to describe the many supply chains of an organisation. Using the singular term indicates that only one approach is required when planning Operations and when responding to an event or disruption. Supply Chain professionals know that planning requires different techniques, dependent on the pattern of demand for different products (or stock keeping units -SKUs).

And a third term is End to End Supply Chain, associated with Visibility through supply chains. But where are the ‘ends’? When a commentator is challenged about the term, it most often means between the Tier 1 customers and Tier 1 suppliers of a business, because this is all that is known. However, the perception can be that the Supply Chains group have infinite knowledge of what is occurring through the organisation’s supply chains.

So, take care of the language used when discussing supply chains with senior managers or other disciplines – note that it is unlikely an accountant will use ‘buzz’ words when presenting a financial report. Allied to this, be ready to define any term used concerning supply chains and importantly, ask people selling IT applications and Logistics Services to define the terms they are using. This ensures that all in the room have the same understanding of what is being proposed.

Suppliers and Supply Chains

Companies that in the past would have designed, built and delivered products may now only design, final assemble and quality assure the same products. This has enabled development of a business model where multiple Tier 1 suppliers provide items ready to be assembled and these suppliers can be located anywhere.

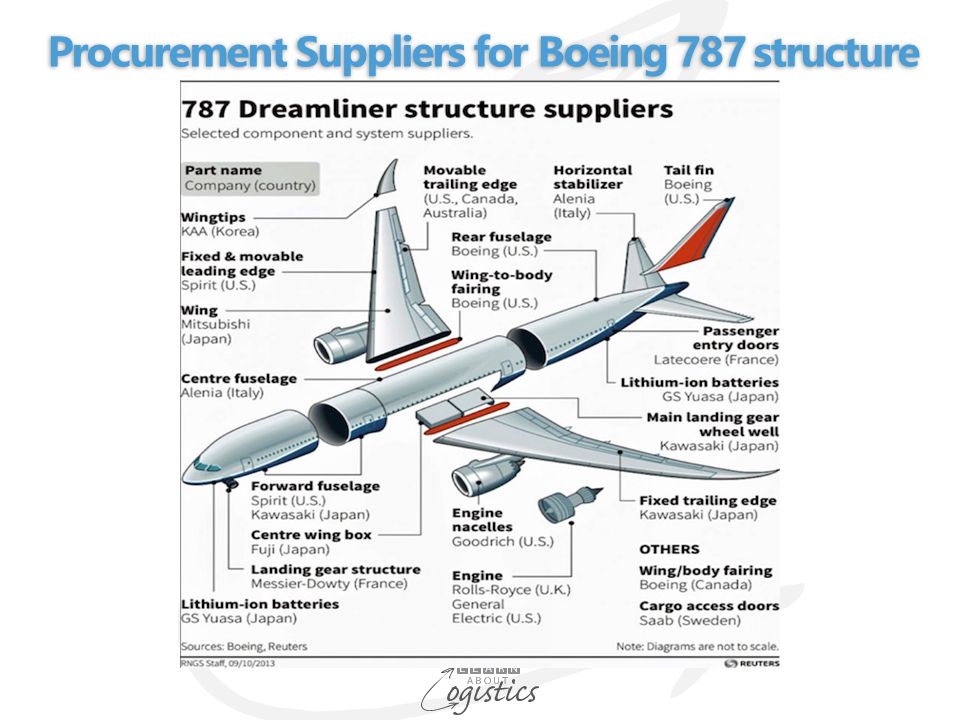

The diagram below shows the range of Tier 1 suppliers for the outer airframe structure of an aircraft, identifying suppliers (including divisions of the business) located in multiple industrial countries. In addition to this diagram, are globally located Tier 1 suppliers for the interior fit-out, fuel systems, controls and electronics. And each of these Tier 1 businesses has their suppliers and those suppliers have their suppliers – a complex supply chains network.

Supply Chains are identified by tiers of suppliers, from Tier 1 that provide direct supply to a business out to the furthest linked supplier in the chain. The shape of inbound supply chains is often an ellipse, with relatively few Tier 1 suppliers, many more suppliers at Tier 2 and may be a few suppliers at Tier 3. At Tier 4 (raw materials), there may be many or few suppliers at the mines and farms.

The diagram below illustrates the generic structure of an organisation’s supply chains. In the centre is the organisations Supply Chains group (Procurement, Operations Planning and Logistics). The Core supply chains comprise those between Tier 1 customers and suppliers, which includes the Logistics Services Providers. The feature of Core supply chains is that the relationships and risks can be managed. The multiple tiers of suppliers and customers that are upstream and downstream of the Tier 1 suppliers and customers comprise the Extended supply chains. They can be located anywhere and cannot be ‘managed’, only understood.

A challenge for a Supply Chain group is that relatively few disruption in supply chains are caused at Tier 1 suppliers. The disruptions occur at the lower tier supplier Nodes (for activities and inventory) and transport movement Links that make up an organisation’s Supply Chains Network. Not surprisingly, the Supply Chains group (the ultimate purchaser) may have little or no knowledge of the Nodes and Links beyond Tier 1. Only when a disruption severely affects supply is there publicity, which upon investigation, may show that the disruption is at Tier 3 or 4, where there are only one or two suppliers of a basic chemical, formula or ingredient for the world market!

So, it is necessary for members of the Supply Chains group to set expectations with their CEO and senior executives concerning what can be achieved through the supply chains, given the resources allocated and the time allowed. This requires that everyone has the same understanding and acceptance of the terms used – not an easy task!