Flows in Supply Chains

The critical perspective of your organisation’s supply chains’ success is not the efficiency of individual departments, but the effectiveness of Flows that provide customers with their orders ‘in full, on time, with accuracy’ (DIFOTA).

A Flow in supply chains is a process, or ‘how things are done’. A business is likely to have between five and seven supply chains, typically based on the:

- incorporation of certain ‘critical’ materials in the Bill of Materials (BOM),

- use of particular equipment, machine assets and facilities (e.g. cold rooms) or

- specific customers (e.g. different automotive assemblers)

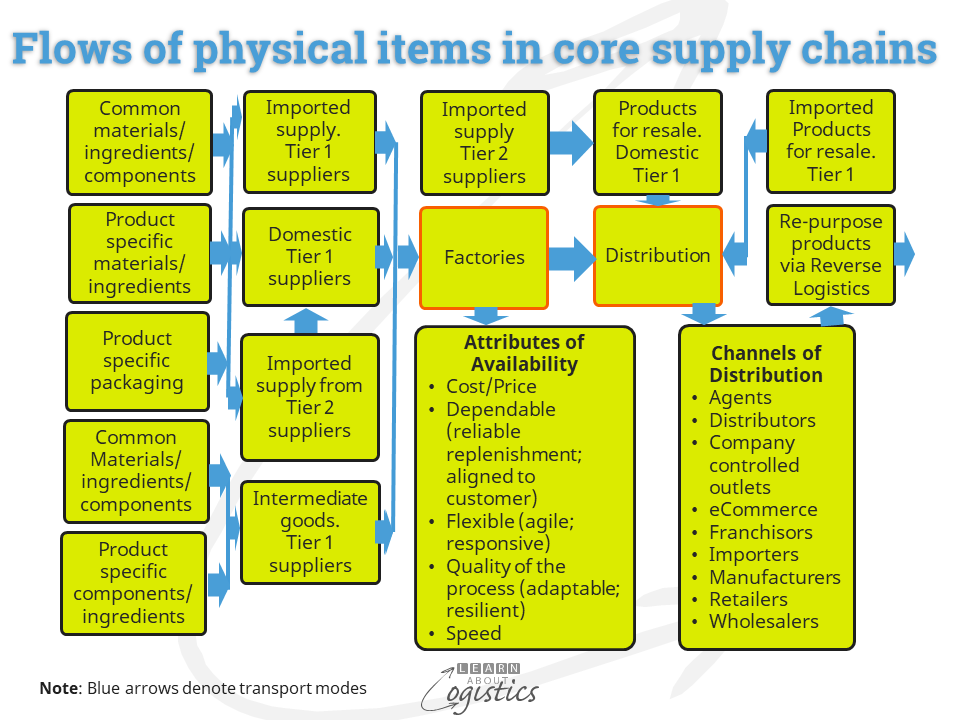

For the Supply Chains group, there are process Flows for physical Logistics, Operations Planning and Procurement. There should also be process Flows for support areas such as Sales, Customer Service and Supply Chains finance, legal and IT. The physical Logistics Flows can include:

- inbound items (materials, intermediate goods and packaging) from Tier 1 suppliers

- finished products for resale from Tier 1 suppliers

- internal movements from company or contracted factories to distribution facilities

- a factory supplies another factory within the business

- deliveries to customers from distribution facilities (could also be direct from factories)

- customer-service related Flows, such as service parts and

- reverse logistics Flows (product returns to re-purpose items, recycle containers, etc.)

The Flows can often involve, via contracts, the movement and storage of items by logistics service providers (LSPs), that include 3PL distribution businesses and transport modes.

The need to map Flows

Often, organisations have not modelled the multiple Flows of physical items. They have also not identified the money and information Flows that support the physical Flow processes. Nor have they documented the current and future capabilities (facilities, equipment and people skills) available and needed to support the Supply Chains.

Disruptions to supply chains in the 2020s have brought to attention the need for organisations to understand the critical connections in their supply chains. These can be at any point through the many levels of supply. A previous blogpost discussed the regulatory requirements in the EU and in Germany for mapping an organisation’s supply chains, which are operative from early 2023.

Mapping your organisation’s Supply Chains Flows is the initial step in the development of the larger Supply Chains Network Design Map – a big picture of the extended supply network for the business. This provides details (when available) of Tier 2 and 3 etc. suppliers (Nodes in the Network) and their factory and warehouse locations, plus ownership or control of Nodes and movement Links, in addition to details of other aspects concerned with International Trade.

So, to commence the project, the Flows through the ‘core’ supply chains (from Tier 1 suppliers, through the organisation, to Tier 1 customers) must be described. Only when that is completed, can the ‘extended’ supply chains (out from Tier 2 suppliers and customers) be documented.

An example of a process Flow for the physical movements through the ‘core’ supply chains of an organisation are shown in the diagram below. Identify the paths by which materials and/or products enter your business, move within the facility(s), are stored and move to customers. However, when mapping Flows, always commence with the customer and work back through the process; this enables the identification of ‘odd’ occurrences.

As part of the documentation attached to the physical Flow, the diagram shows that under ‘Factories’ is listed how Availability is provided for customers. Under ‘Distribution’ are the Channels of Distribution that can be attributed to supply chains, product groups and individual stock keeping units (SKUs).

The next step is to document the Money Flow – identify when money enters and leaves the business and the time horizons in which this occurs. Then document the ‘Data and Information’ Flows that accompany the physical and money Flows.

Within the ‘core’ supply chains, the business, its customers and suppliers and logistics service providers are likely to have a mix of communication methods that must be documented and understood for their strengths and weaknesses. Identify the type of data and information flow and the issuer and receiver – such as:

- system to system – EDI

- system to person – access current inventory status

- person to system – update a goods movement

- person to person – phone call or fax

In addition, it is preferable to identify the supply chains and functional competencies required at each stage through the physical Flow. Also, the supply chain capabilities that should be expected and how they will be obtained and implemented.

To assist the project, there are Process Flow software products available, which usually provide templates and a visual output; LucidChart is an example. Visualisation enables people in the organisation to more easily identify unnecessary steps, duplications and weaknesses in the Flows.

Benefits of mapping Flows

Developing a ‘core’ Supply Chains Flows Map enables each physical flow to be better understood. It provides the opportunity to consider standardisation within the Flows, integration of stages and the potential for different approaches that can include new software applications and automation.

It can also highlight gaps in the current capabilities of the organisation, including the co-ordination of internal data and information. For Operations Planning, it can help to identify possible areas for Flexibility. One is the potential use of Postponement in the physical Flow – where value added and/or product customisation can be delayed until later in the production or delivery Flows.

Internally, the Flow map can assist with decisions about current and future software application requirement that may assist Flows through the supply chains. For outsourcing of functions, such as Logistics operations, the current and future data and information Flow requirements can be identified, including any required IT integration or interfaces with contracted businesses.

Modelling the Flows of an organisation along the three dimensions (items, money, data & information), with comprehensive support documentation is a structured mechanism for understanding internal systems and external contract and relationship requirements. Value can be added to the project when used in conjunction with the Sales Market Segmentation Map, when it is structured around the service requirements from the Supply Chains group.