Collaboration is required for S&OP

Collaboration is what people are able to do when they perceive a mutual advantage. A supply chain professional understands the importance of cross-function collaboration and recognises that it does not require Slack, Teams, Zoom or other technology, system or application, although a well designed app can help.

The previous blogpost discussed how planning Operations can be affected by Sales decisions and an earlier blogpost discussed the ‘One Plan’ approach for your supply chains. These and earlier blogposts illustrate the importance of the Sales & Operations Planning (S&OP) process, because it enables constructive discussions about issues and challenges and to identify a capability to balance demand and supply.

Success with S&OP will help acceptance of the Supply Chains group (Procurement, Operations Planning and Logistics) by other functions within the organisation. It is therefore in the self-interest of the Supply Chains group to promote Collaborative relationships with other functions. To drive the Collaboration process is a role for the Supply Chains executive responsible for ‘flows’ through the supply chains (of items, money, data and information). If your organisation does not have such a person, then the process will most likely fall to the senior Logistics executive.

Steps to Collaboration

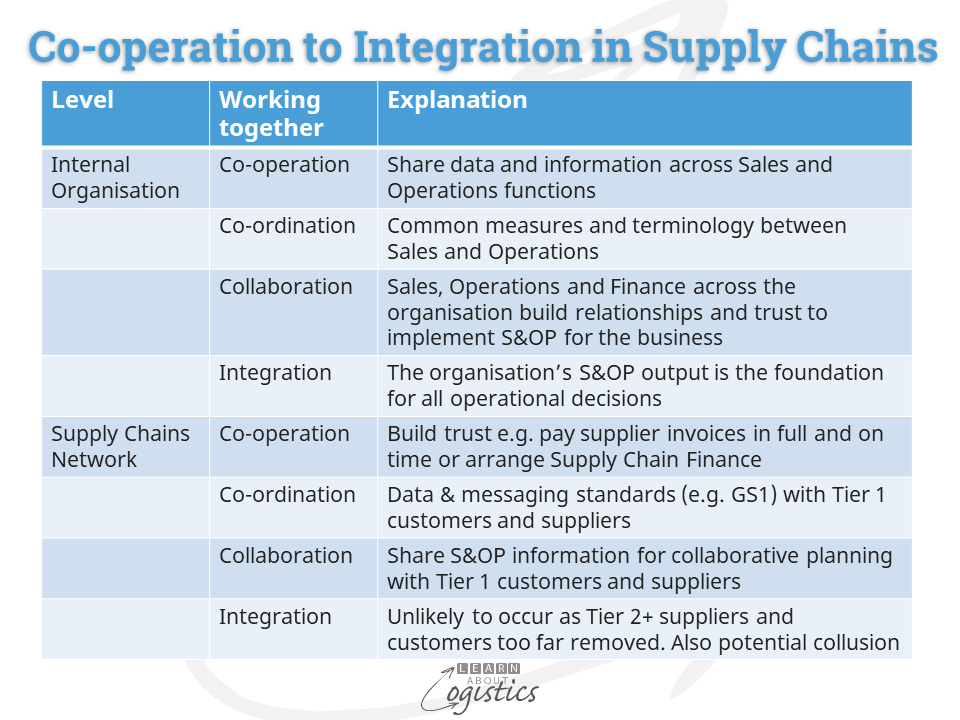

The diagram illustrates that Collaboration is harder to achieve than to spell – it requires the prior implementation of Co-operation and Co-ordination, both internally and externally.

Co-operation sets the tone for relationships within a function and between functions. The vehicle for Co-operation is Management By Walking Around (MBWA). This is your opportunity as a manager to identify what is actually happening, rather than rely on the numbers. If you don’t constantly monitor how people and their team is, or is not performing, they could think that you and senior management are not serious about the plan or schedule.

MBWA requires that you leave the computer and walk around the supply chain facilities where you have responsibility and talk to your people. Not just about the business and challenges they have in effectively doing their job, but also their values and attitudes. This indicates respect. As a former chairman of Toyota said “Go see, ask why, show respect”.

MBWA is an informal and spontaneous way of keeping in touch, to find out whether your area/function is heading in the right direction. It requires you to be accessible and easy to approach and important for the process is your role to listen. This is also an opportunity to keep people informed about happenings in the organisation, especially those which are important to them. The fun part is that you also learn what people do away from work to gain a ‘work-life balance’ – run a small business, chair or coach at a sporting club, member of a gardening club etc.

People are similar in terms of the way they respond positively when barriers are removed and they are recognized as individuals. Four perceived ‘truths’ about people working in an organisation were identified in the early 1990s,by Jan Carlzon in his book Moments of Truth:

- Everyone needs to know and feel they are needed

- Everyone wants to be treated as an individual

- Give a person the freedom to take responsibility. This releases resources that would otherwise remain concealed

- An individual without information cannot take responsibility. A individual who is given information cannot help but take responsibility

Enabling MBWA within the Supply Chains group (or even initially within Logistics) provides the confidence to extend MBWA to those in Sales and Marketing that are willing to engage. The mutual topic of interest is inventory and how the current deployment can be improved. The discussion is under the headings of:

- The locations where inventory should be held, to meet customer service requirements and minimise stock-outs

- In what form should inventory be held at these locations and

- For what inventory function: cycle and fluctuating; anticipation, in-transit, hedging

The analysis should also provide a ‘Cost to Serve’ calculation for each customer segment, that balance the likely Sales view of customer expectations against the cost of Supply Chains operations. These approaches show a willingness for Co-operation, which leads to the next step of agreeing on areas where Co-ordination of data and measurement is required.

The discussions enable Sales and Marketing to explain their challenges and how they see the Supply Chains group helping. It can lead to Sales and Logistics people jointly talking with customers about the flow of items into and through the customer’s facilities: delivery problems at the customer’s receiving dock and delays in the items being used; such as: QA testing, repacking into usable pack sizes, transfer of documents etc

With both sides gaining a better understanding of the challenges and possible solutions, can lead to a person within Sales or Marketing becoming the ‘champion’ who promotes the proposal within their function to be part of a S&OP process.

In parallel with the approaches to Sales and Marketing, trust can be built with Tier 1 suppliers through Procurement and Operations Planning joining forces. These meeting will discuss the challenges in serving the organisation and developing an improvement focus to achieve ‘clean’ transactions through all steps in the ordering and delivery process.

The collaborative approach across functions provides confidence to discuss with Finance a proposal for a collaborative S&OP process within the ‘One Plan’ approach. With the agreement of all parties, the proposal is then submitted to the profit responsible person (CEO, country manager, factory manager etc). What may appear to be a time consuming exercise is necessary to gain people’s confidence in the collaborative approach to tactical planning that requires:

- Trust – that other parties will share data, information and commitment

- Commitment to the long-term success of the S&OP process

- Joint decision making through the S&OP process

- Sharing risks (e.g. wrong decisions) and benefits

In summary, Collaboration has three elements for a Logistician:

- Management by Walking Around (MBWA) – you only get half the story (or less) by sitting in front of a computer screen. As a manager in supply chains your objective is to spend about 40 percent of work time devoted to MBWA

- One Plan for the organisation. Includes the collaborative S&OP process which enables all employees to work from the same Plan

- Plan B at the Sales & Operations Execution (S&OE) level (but based on the S&OP). Understand the elements of Uncertainty (Complexity, Variability and Constraints). Know the potential weak points in the supply chains and build into the S&OE a process to identify potential options in the event of failure. Ready to implement when Plan A fails.

It is mid-winter in Australia, so Learn About Logistics is taking a holiday. The next blogpost will be on August 29. For additional reading, David Rogers has articles at Articles | Insync Supply Chain Management (iscm.com.au). For those with an interest in Space Logistics, there is an article at Very proud that the article Adrien PALUN and I wrote for ROOM – Space – Paul Lascombes on LinkedIn