Supply Chain definitions

Understanding the scope of a challenge helps in defining how to structure and implement the solution. So it is with supply chains.

Supply chains are not new; they have existed since people commenced trading items. But, the term itself was first used in an article written in the early 1980’s and commenced adoption in business about ten years later. With publicity concerning the current US-China trade dispute and the UK ‘Brexit’ decision, the term supply chains has entered into general conversations, but similar to the term Logistics, without much understanding.

Unlike other professions, defined and approved definitions do not exist in the world of supply chains. So, to assist readers, some Learn About Logistics definitions and views are provided and expanded upon.

Definitions and views

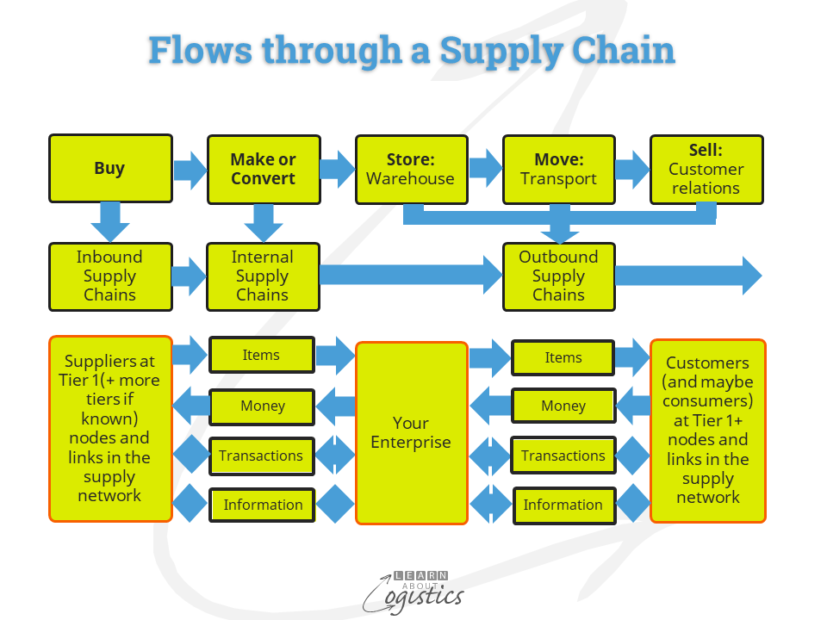

Supply Chains are the activity ‘nodes’ and movement ‘links’ within an organisation and between enterprises which provide value for end users in the supply and ‘end of life’ of material and service items, at the lowest total cost. A supply chain consists of two parts:

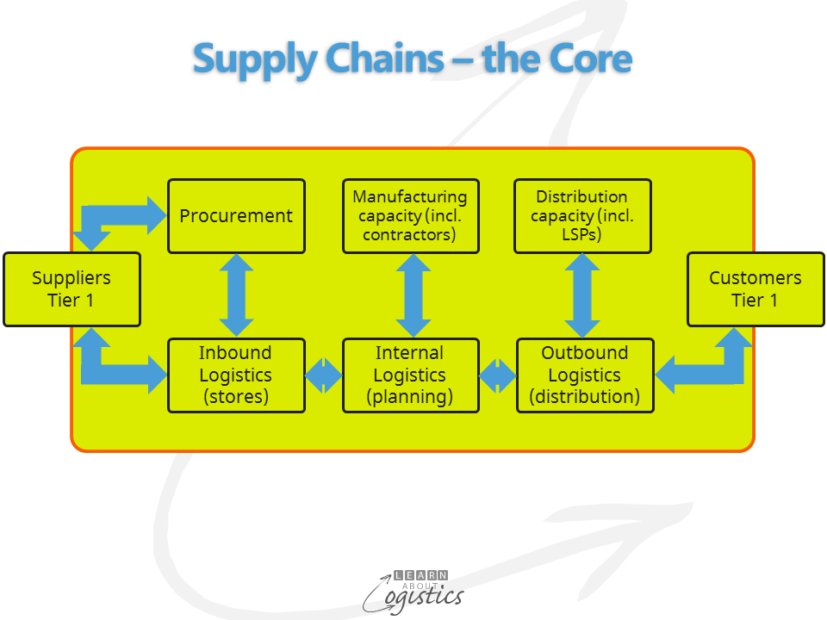

- Core supply chain: incorporates the flows of materials, money, transactions and information between Tier 1 suppliers, through the organisation and out to Tier 1 customers. The Core can be planned and scheduled

- Extended supply chain: Identifies the flows outwards from Tier 2 supplies and Tier 2 customers. This environment should be researched, analysed and understood for possible changes

The ‘Perceived Value’ of an item is initially assessed by the purchaser based the brand, its identity and intangibles; but value is also provided through supply chains:

- Place and Time Value: Processes to provide Availability of items (including speed, flexibility and reliability)

- Function and Form Value: Cost, manufacturing quality and service delivery of items

Value in a supply chain is also influenced by the:

- power imbalance between parties in contracts

- dependency of an organisation on a supply chain

- risks in a supply chain

- management of relationships in a supply chain

Supply Chain Management is managing internal and inter-organisation relationships with customers and suppliers that enable the effective and efficient use of resources in the process of planning, buying, moving and storing items, to achieve customer service objectives

Supply Chain Strategy requires the amalgamation of strategies developed by the core operational disciplines of: Procurement, Operations Planning and Logistics (which may or may not be part of a single group):

- Procurement: the processes by which an organisation understands their supply markets and contracts with suppliers to obtain goods and services required to fulfil end user needs and items for the ongoing needs of the organisation, in a timely manner and at lowest total cost

- Operations Planning: effective planning of people, materials, equipment, facilities and inventories within an organisation to supply items for customers, efficiently and at the lowest total cost. The main input should be the Sales & Operations Plan (S&OP)

- Logistics: the time related positioning of items and internal and external resources to provide Availability of goods and services to meet end user needs at the lowest total cost

There may also be additional disciplines within a supply chains group, such as: tactical marketing and sales (including customer service and order management): import/export compliance and supply chains IT, finance and legal.

Availability is the responsibility of Logistics. It is the capability to Deliver (items and associated services) In Full, On Time with Accuracy (DIFOTA) to meet customer requirements. Availability contains three functions:

- Physical availability: (Customer Service) – inventories; outbound distribution, storage and transport

- Reverse logistics – to re-purpose goods (including disposal) through the return of items

- Support availability – post-sales support and service of products. Also the planning and scheduling for life cycle support (maintainability and supportability) of an organisation’s internal infrastructure and capital equipment. In the military this is referred to as Integrated Logistics Support (ILS) and Logistics Systems Analysis (LSA)

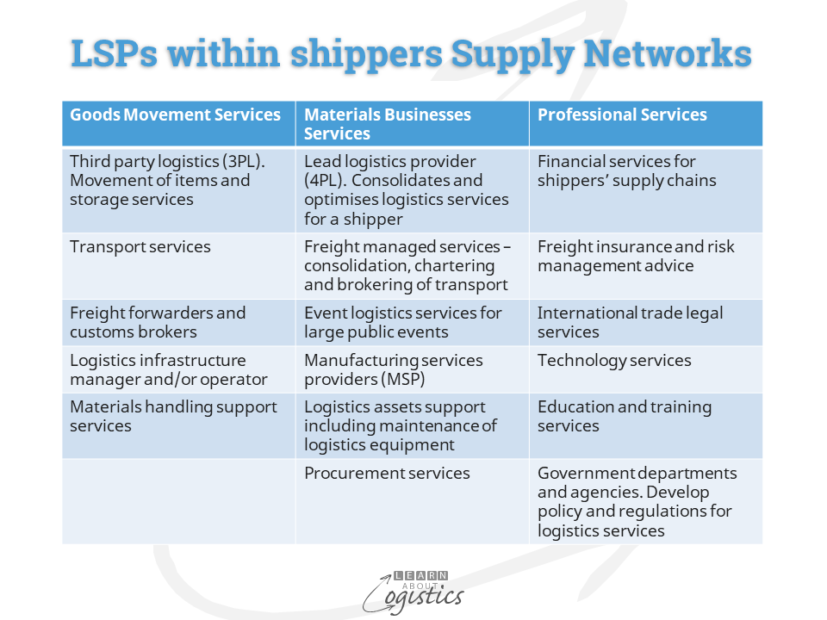

Each discipline and logistics function contains a planning (thinking and calculating) and physical (doing) element. Each can be performed internally by the enterprise or contracted to external specialist Logistics Service Providers (LSPs).

A Supply Network: the multiple supply chains which comprise an organisation’s network of interdependent and IT connected suppliers and customers.

A Supply Network is a Complex Adaptive System (CAS): “a system that emerges over time into a coherent form, adapting and organising itself without a singular entity deliberately managing or controlling it” (Holland 1995).

Uncertainty is generated in an organisation’s CAS Supply Network, due to inherent issues within end user and supply markets and at customers, contractors and suppliers. Uncertainty consolidates the possible disruptions for an organisation caused through:

- Complexity: internal (often management directed) and external processes

- Variability: in patterns of demand and supply

- Constraints: interruptions in the Flows of items, money, transactions and information through supply chains

A CAS structure means that players in the network interact dependently, independently and interdependently, relative to their positions on the time line flow. As Uncertainty factors interact and amplify each other, they create Emergent results, which are Cumulative. This influences the frequency of disruptions in supply chains and therefore Risks to an organisation.

Supply Chains Risk Management: The structured identification and assessment of uncertainties which provide potential risks within an organisation’s supply chains and the development of mitigation approaches to avoid or minimise the consequences.

Supply Chains Risk Management is a responsibility of the supply chain group of disciplines. This is because the different types of risk can influence the decisions and actions of more than one discipline in the group.

When referring to arrangements between parties in supply chains, the terms ‘partner’ and ‘partnership’ are not used by Learn About Logistics. The dictionary meaning is “sharing of risk and reward”, which is rarely, if ever, achieved in a commercial business contractual relationship.

In summary, Procurement, Operations Planning and Logistics add value to items and services, through relationships, negotiation, planning and scheduling to satisfy end user demands. Supply networks and supply chains are the environment through which items are purchased, sold, moved and stored for an organisation.