New terms and perceptions

The disciplines that engage with supply chains receive a continual upgrade to their vocabulary. New terms are added and promoted without much thought about their meaning and more importantly about perceptions by executives at the peripheral of supply chains.

An example has been the recent use of the term Command and Control in relation to obtaining Visibility through supply chains. What would be your reaction be if told to use ‘Command and Control for end to end visibility through the supply chain’? The reaction from Learn About Logistics is to ask the speaker for an explanation of what the sentence actually means.

Meaning of terms in the statement

Command and Control is a function of ‘top down’ organisation structures, such as the military and organised religions, (e.g. the Catholic church). The main features are a vertical ‘chain of command’, with stated authority and responsibility for discipline. There are defined policies, procedures and processes which articulate why and how an action shall be done. When a supply chain organisation is structured as Command and Control, it tends to be inflexible, rigid in procedures and unresponsive to customers and suppliers.

The ideal Supply Chain organisation has a horizontal structure that aligns the Supply Chain group (Procurement, Operations Planning and Logistics) with the flows of items, money, information and data. It is easier for a horizontal structure to be flexible and pre-empt or respond to changes in the supply network. However, ‘flexible’ and ‘agile’ does not mean a ‘free for all’. Controls are exercised at the point in the process which separates satisfying customer orders from planning operations. This is the point at which customer orders are accepted and reserved; final product specifications are defined and the last point from which inventory is released.

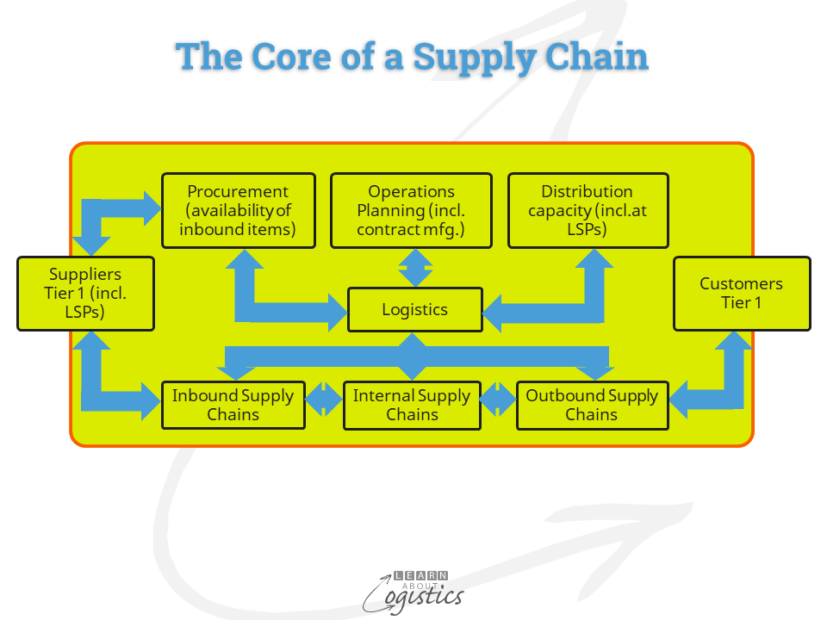

End to End: From where to where are the ‘ends’? The diagram below illustrates an organisation’s ‘core’ supply chain. This is the extent of knowledge about supply chains used by the great majority of organisations and is their actual ‘end to end’. However, the ‘extended’ supply chains extend from the tier 1 suppliers and customers to their suppliers and customers and so on to the farms and mines from where raw materials are obtained. They have their own supply chains for inputs to operations. At the other end are the places at which the end users purchases the item. So, where are the two ‘ends’?

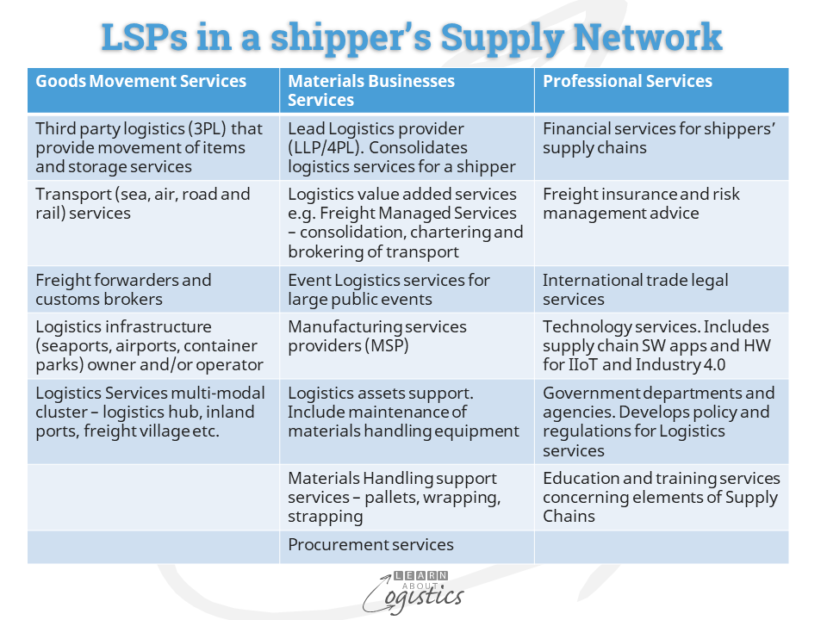

Also, within your organisation’s core supply chains, are contract manufacturers and Logistics Services Providers (LSPs), which are defined in the table below. These businesses have their supply chains, from which a disruption may affect a shipper.

Within the ‘goods movement services’ group are ports. A recent report identified that a very high percentage of global tier 2 ports do not have capable systems and communication facilities for transmitting data about ship and cargo movements.

Within the ‘materials business services’ group are suppliers of ‘materials handling support services’ – pallets, wrapping, strapping etc. For pallets, the expectation is that when a business requires additional pallets they can be purchased or hired – that is, until they are not available! A recent media report noted that in the US, the price of wooden pallets has risen 400 percent and availability is tight, such that suppliers are unable to complete additional orders at the peak of agricultural harvest. The cause is attributed to both demand and supply factors.

As pallets are unlikely to be included in a Bill of Materials (BOM), prospects for their supply would not be known until the disruptions actually happen. So, does ‘end to end’ have another ‘end’ within LSPs?

Supply Chain Visibility: This is the capability to locate an order or an item’s in-transit location within a supply chain, ideally in close to ‘real-time’; achieved through IT technologies that enable ‘track and trace’ of orders and items. The capability to track a parcel is established. To ‘trace’ an item (Supply Chain Traceability) is to establish the item’s provenance through its supply chain. That is, substantiating and recording claims made about an item, concerning such aspects as its origin, material properties and types of labour used.

An earlier blogpost discussed the two aspects of Visibility – to ‘see’ (i.e. track) and to ‘map’. Supply Chain Mapping identifies the flow of items, money, information and data through the nodes and links of each supply chain within an organisation’s Supply Network. It incorporates Supply Market Intelligence (SMI); the process of creating a supplier capability for each supplier and their markets, including the extent of power or dependency. Mapping is a continuous process, as additional details that enhance understanding are obtained.

Also associated with visibility is Supply Chain Transparency. This refers to whether and then how an organisation will disclose information concerning its supply chains (including sourcing) to relevant parties, including customers. The extent of an organisation’s Transparency is defined by: what data will be supplied and in which format; to whom will it be given; under what circumstances; when or how often and using which technology.

Within each shipper organisation is Operational Visibility: This is the capability to provide Visibility within their operations to identify the status of any order or item. This may involve an interconnected IT network of commercial and technical systems that have Industrial Internet of Things (IIoT) sensors monitoring machines, as discussed in a previous blogpost.

Supply Chains and Networks

The supply chain, which is a singular term, is often used, for reasons unknown, to denote the plural. An organisation will typically have more than one supply chain, therefore the term used should be supply chains. When discussing an organisation’s supply chains, the better term is supply network. This recognises that an organisation’s supply network is a ‘complex adaptive system’ (CAS), that adapts and organizes itself without a single entity managing or controlling. Researchers have identified that an organisation’s supply network is not a system that can be planned, managed and controlled and certainly not through command and control.

While all businesses would like to have total Visibility of their supply network, this ultimate goal will not happen soon, if ever. However, any delay provides opportunities for organisations to address the challenges within their own organisation that hinder the adoption of Visibility. These include the lack of co-operation, co-ordination and collaboration within organisations to ensure an achievable supply chain plan; ineffective use of data and information; the lack of synergy between IT applications and the inability to predict and prepare for risks in supply chains.