Supply Network in the media

What a surprise to read an article in a mainstream business magazine that uses the term Supply Network and the words Complex and Uncertainty all in the same paragraph! The virus crisis and its economic shocks are showing that supply chains have a use beyond just cutting costs.

Similar to Logistics written on the side of so many trucks, the term Supply Chain has become misused. This has allowed terms to be invented that do not convey a correct meaning, such as:

- ‘the supply chain’ – there are multiple supply chains within each organisation, industry and economy. The term should reference supply networks

- ‘supply chain management’ – is not about managing other enterprises, instead it is ‘managing internal relationships and external relationships with customers and suppliers in the process of planning, buying, moving and storing items’.

As Supply Network has now entered the mainstream media, the term needs to be differentiated from Supply Chains. This can provide the background for those occasions when you present the organisation’s Supply Network to senior management.

A Supply Chain

The term Supply Chain was first mentioned in an article of the early 1980s and accepted into business use about ten years later. Prior to that, research commenced in the mid-1970s in Scandinavia concerning the network model of organisations. In the mid 1980’s, researchers attached to the Santa Fe Institute in New Mexico developed the theory of complex systems, based on natural systems such as bees and ants. The model was modified to fit the perspective of business, with the premise that commercial trading is undertaken by networks of independent organisations. These adapt to meet the (unwritten) goal of a network, which is end user satisfaction.

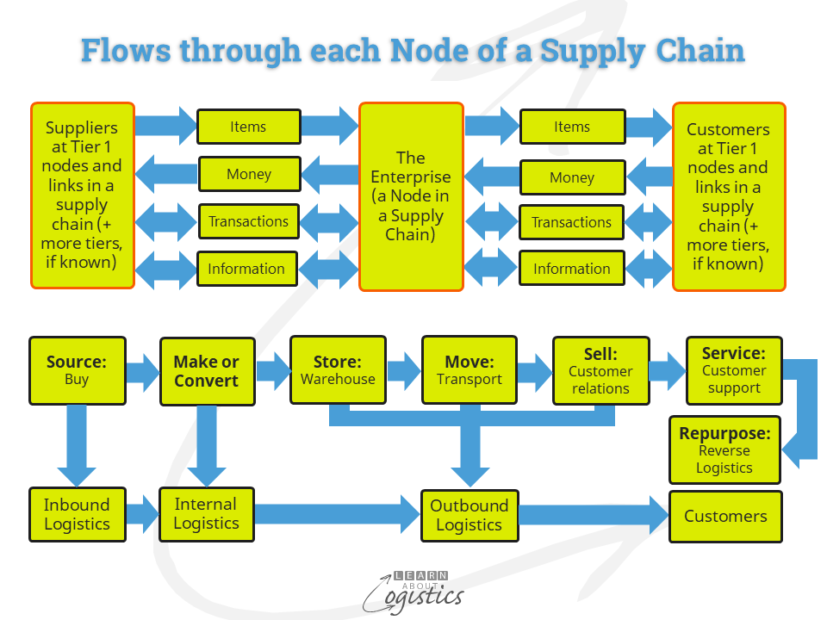

The definition for the term Supply Chain used by Learn About Logistics is: The effective flows of items, money, transactions and information between supplier and customer enterprises, through ‘activity nodes’ and ‘movement links’ at each stage of an extended supply chain, to provide value for end users at the lowest total cost. The following diagram illustrates this concept.

A supply chain consists of two parts:

- Core supply chain: incorporates the flows of materials, money, transactions and information between Tier 1 suppliers, through the focal organisation and out to Tier 1 customers. This includes Tier 1 Logistics Service Providers (LSP). Core supply chains need to be planned and scheduled

- Extended supply chain: Identifies the flows outwards from Tier 2 supplies and Tier 2 customers. Extended supply chains should be researched, analysed and understood

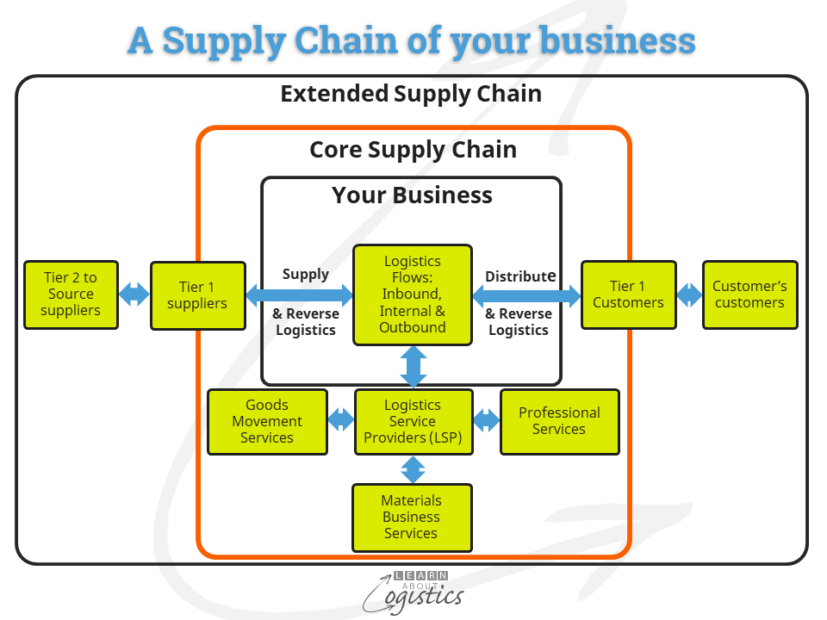

The diagram illustrates this concept for your business:

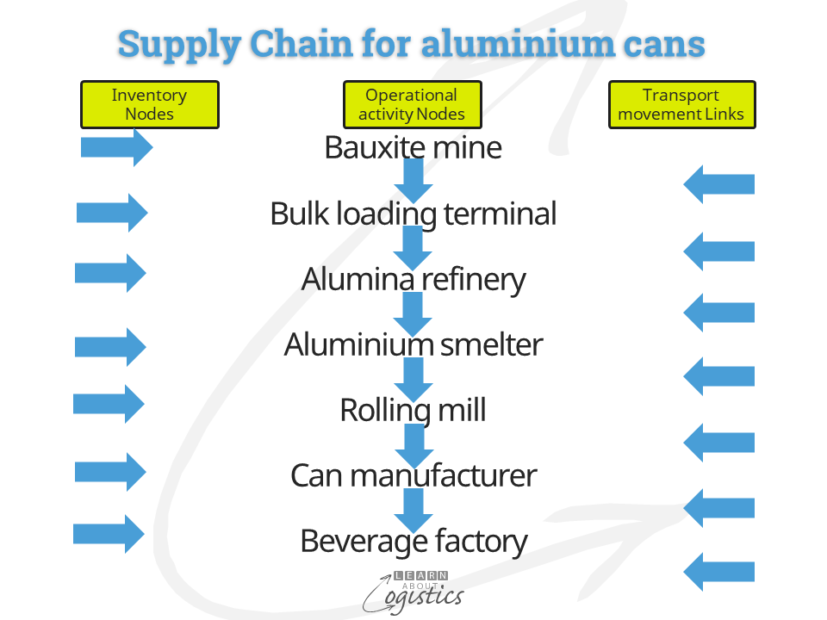

To put this approach into context, the next diagram illustrates the supply chain for aluminium cans used in the beverage industry. There are six suppliers in the chain prior to the beverage factory, but the factory’s Tier 1 supplier is the can manufacturer. All others are part of the extended supply chain for the can, where the beverage company has little or no relationships.

From the viewpoint of planning and scheduling through the supply chain, the bauxite mine has one operational node, one inventory node and one transport movement link. All other suppliers have two inventory nodes (inbound and outbound). As the suppliers are likely to be geographically far apart, uncertainty and complexity concerning availability and operations in the chain will exist.

A Supply Network

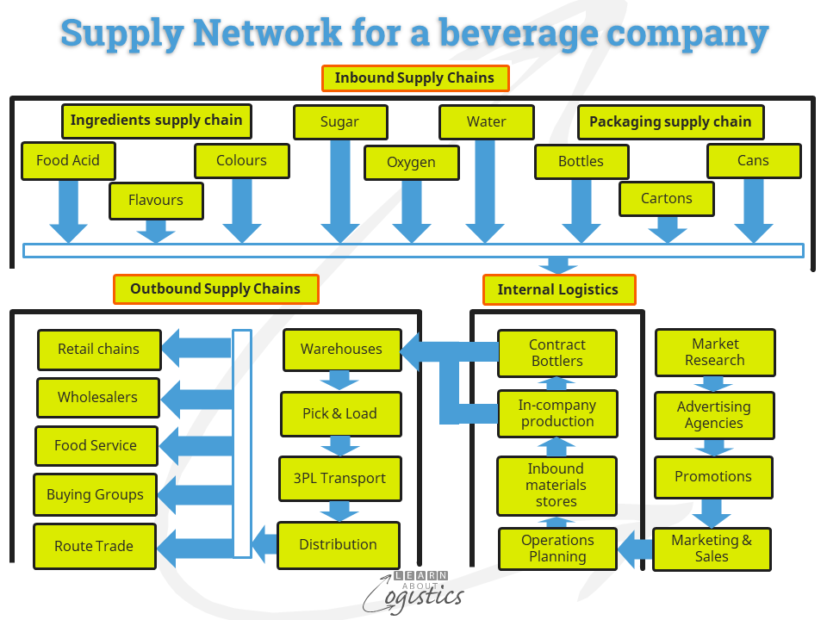

The definition used by Learn About Logistics is the multiple supply chains that comprise an organisation’s network of interdependent, but connected, suppliers and customers. This concept is illustrated in the diagram below:

Items that are likely to be similar in their ordering, transport and handling processes, may be placed within one Supply Chain, as shown in the diagram for ‘ingredients’ and ‘packaging’.

Together, the diagrams for the aluminium can and the beverage company show that an organisation’s Supply Network can be complex; in fact it is a ‘complex, non-linear system’, or Complex Adaptive System (CAS). A definition is: ‘a system that emerges over time into a coherent form, adapting and organising itself without a singular entity deliberately managing or controlling it’ (Holland, 1995).

Features of a Complex Adaptive System

A CAS cannot be ‘managed’, but can be analysed and understood. The essential features of a Supply Network as a CAS are:

- Emergent and Cumulative: refers to the outcome of events, which cannot be predicted with any certainty and over which an organisation’s management has little control

- Adaptable: Independent entities at the nodes and links of each supply chain respond to changing situations based on their own interests. These responses cannot be predicted

- Non-linear: many ‘ifs and thens’, as in a Decision Tree diagram

- Uncertainty: the lack of predictability concerning the cause and effect of events. Uncertainty is heightened with increased flows of items, money, data and information. Uncertainty is the basis for Risk Management

- Complexity, Variability and Constraints. These elements of Uncertainty can interact dependently, independently and inter-dependently, to affect outcomes and increase Uncertainty. The elements are amplified by the level of acceptance in an organisation’s business model concerning the:

- Distances (and therefore lead times) from the organisation to its suppliers and customers

- Focus within the organisation’s operations on speed and efficiency rather than effectiveness

- Low safety margins concerning time, inventory and working capital

The uncertainty and complexity of Supply Networks that has emerged in the virus crisis may cause organisations to choose a more cooperative approach in their Supply Networks. Improving the flows of items, money, data and information between primary suppliers, logistics service providers (LSPs), customers and end users could provide unexpected benefits.