S&OP flow in your business

Sales & Operations Planning (S&OP) is not a difficult process to follow – the challenge is to make it happen! The objective is to improve the balance through supply chains, between expected future demands for the organisation’s products and services, the organisation’s resources and the supply of purchased or intra-company provided items. And, of course, how the output from S&OP will be financed.

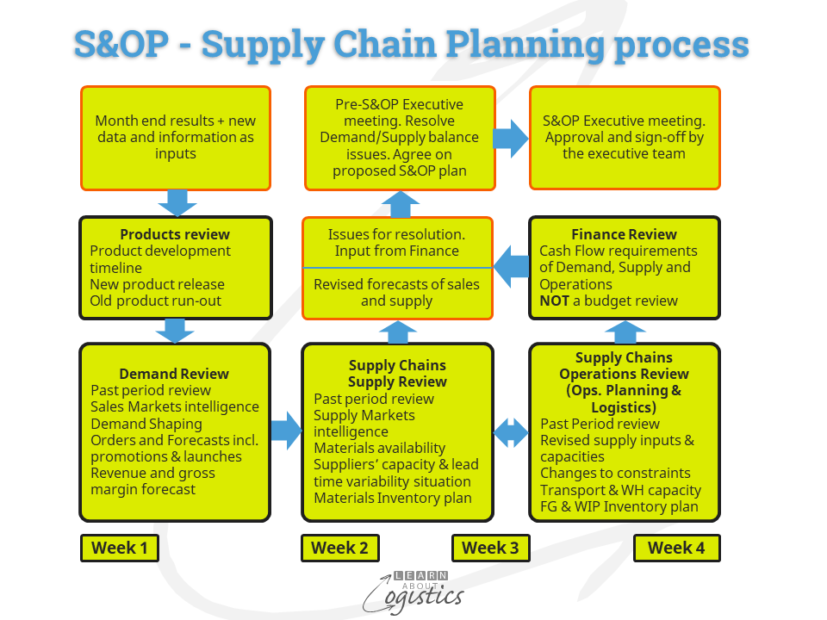

The previous blogpost was a call to supply chain professionals that the discipline is under a potential threat of takeover by Finance. This can be achieved by Finance assuming responsibility for the S&OP process, as many businesses have yet to implement the concept. Instead, the absence of S&OP provides an opportunity for supply chain professionals to sell the planning concept to senior management. The diagram provides a structure of the S&OP process:

S&OP is useful for organisations that make and distribute products. The principles and process of S&OP is also applicable to any operational business through a supply chain – importers, outsourced or contract out operations, logistics services, a loading terminal for commodities or a shipping container park.

A structured process for planning

When structuring you S&OP implementation plan, the main features to consider are:

- Products (stock keeping unit or SKUs) are aggregated into ‘families’. As output governs what a business can sell, S&OP ‘families’ are based on the capacity and capabilities of resources within ‘Operations’

- In some circumstances, ‘families’ may reflect the few brands or models that are supplied to major customers, such as when supplying to automotive assemblers

- The number of families varies between 5 and 15 (preferably in a range of 6–12)

- A standard unit of measure is used for both ‘sales’ and ‘operations’ e.g. shippers (the carton size shipped to customers), tonnes, litres, pallets, hours etc. Note: The Demand Plan will most likely have a standard unit of measure that converts the selling units to the Demand Plan unit of measure

- The S&OP process provides a focus on planning the tactical horizon over a forward period of 3 – 18 or 24 months. Note: the current and next month (at least) are not considered in S&OP

- The S&OP process cycle is typically monthly. However, to obtain consistency of measurements, consider 13 x 4 week periods per year

- S&OP reviews are by product ‘family’, using the standard unit of measure. This provides a consistent communication base across all functions and entities.

- Sales forecasts (including product returns and credit notes) for each product group in the Demand Plan are transferred to the S&OP ‘families’. Forecasts are summarised by market segment/territory and SBU/division totals. Provide a sales variance of (say) +/- 5 percent from the weighted forecast (that is weight the optimistic and pessimistic forecasts by their probabilities)

- Inventory is described by form and function for each family at nodes in the supply network

- For each SKU, enable the Bill of Materials (BOM) within the ERP system to ‘roll-up’ into their S&OP ‘family’

- Identify the inter-relationships of SBUs/divisions within the enterprise – global planning authority; region responsibility; matrix organisations (local operations and region/global services) etc.

- Strategic business units (SBU) and divisions must have a common approach in their S&OP, to ensure the numbers will mean the same throughout the organisation. This includes a common definition for demand, supply and planning elements.

The SBU manager, responsible for the P&L, is a critical part of S&OP. Their buy-in to implement S&OP includes gaining support of the management group, which includes issues concerned with perceived power and status by managers. The P&L manager needs to initially ensure a ‘balance’ between the inputs to the process by ‘sales’ and ‘operations’ and other functions, as they learn what collaboration requires.

The P&L manager will write their S&OP policy document. This includes: an overview of the process and its objectives concerning future actions and anticipated results; the participants in the process and their responsibilities (e.g. responsible; accountable; consulted or informed); the expected outcomes from each step through the planning cycle and the S&OP meeting dates and times over the next 12 months.

For meetings, the target time is not more than one hour; to help that happen, meetings should be held late in the afternoon. It will take the first three meetings, with a strong personality as chair, for attendees to understand the one hour rule.

There are two parts for each meeting. The first (and shortest) part is a review of recent performance and lessons learnt (called the past period review). The second and longer part of the meeting is the intended plans and actions to meet future customer demands, set against the most likely internal capacity and capabilities.

S&OP is not a ‘software driven’ process. However, to be effective, the S&OP process requires factual input from all parts of the organisation, so accuracy and timeliness of relevant data and information is required. Over time, a simulation application can be acquired to enable the impact of alternative plans to be modelled against constraints in the markets and business.

Because S&OP is the tactical planning process for the organisation’s supply chains, it is that group which should have the responsibility of guiding the process. Specifically, the Master (or senior) Planner of an SBU should be responsible for facilitating and reconciling the completion of each step in the process.

Towards collaboration

S&OP is a long-term project, which can show some benefits within six months. However, to be successful requires changes in attitudes about working in teams and how ‘success’ is measured at all levels of management – this is about collaboration.

For collaboration through S&OP to become embedded in the organisation will take about three years. The time is required for an education process to affected staff, both current and replacement; revised processes to be implemented; new performance measurements (metrics) developed, used and understood and IT applications proposed, tested, purchased and implemented. It takes times to change the culture in an organisation. The challenge will be a willingness to work at improving the process (and results) over this length of time.

Collaboration can eventually be extended to suppliers. The updated S&OP by each ‘family’ is an input to the Supply & Operation Execution (S&OE) process. This commences with the S&OP converted to SKUs in the Master Schedule (or similar term) in the ERP system. The Master Schedule is the driver for plans concerning inbound supplier items, production and delivery plans and schedules. To reduce uncertainty in supply chains, the ideal situation is for an organisation’s Master Schedule to become an input to the tier 1 suppliers’ S&OP process and those suppliers to then do the same for their suppliers.

This and the previous blogpost provide an overview of the ‘why’ and ‘how’ of S&OP. Use the document to sell the concept and help make it happen. Assistance from S&OP experienced consultants and software suppliers may help, but be careful of those that put their own ‘badge’ on the process by renaming S&OP as ‘Sales, Operations and Inventory Planning’ or ‘Sales and Inventory Optimisation Planning’ etc.