A major change could be happening

We generally have the assumption that things are always changing, but there are epochs (a particular period of time in history) when a more dramatic change occurs. This affects the outlook of governments, such that geopolitical and commercial decisions are made from a different perspective.

And the world could be entering one of those periods of change. The invasion of Ukraine by Russia may be a turning point that affects how countries view others. An article by the research firm Geopolitical Futures considers five epochs over the past 200 years and notes that:

Beginning with the French Revolution, the certainties of the world have shifted dramatically every generation or two. In separating the epochs, it is not simply that a conflict ended and a new power emerged, but rather that the fundamental reality of the world changed – the ideological military confrontation of the Cold War was replaced by a globalist ideology.

Historical Phases and Transitions George Friedman Geopolitical Futures April 22 2022

In the new epoch, ‘Globalisation’ could be replaced by ‘Security’. Geopolitical and commercial decisions would be viewed through the prism of domestic security. This could include preparations for potential invasion, blockade or sanctions; the locations for purchase and inventory of ‘critical’ materials and a more rapid electrification of the economy, using renewable technologies.

Friedman notes the surprising speed at which each new epoch evolves and is accepted as ‘the way things are done’. It could therefore be the right time for your organisation to undertake Scenario Planning of supply chains and so gain an understanding of future possible outcomes and their probabilities. And importantly, the mitigation actions required to have ongoing confidence in the performance of your organisation’s Supply Chains Network.

Scenario Planning structure

Scenario Planning assumes that future developments are largely uncertain. It requires analysis to identify and project trends, possible implications and options for action. Although it is called Scenario Planning, the process is actually Scenario Analysis – the planning comes later. The value of Scenario Planning lies in discussions around options, risks and the likely consequences. When thinking about the environment surrounding future strategies, an approach has the acronym of VUCA, with four conditions:

- Volatility: The speed of change over a period of time, where situations are unexpected, the pattern of events is unstable and the duration is unknown

- Uncertainty: the potential for surprise and a lack of predictability concerning an event’s cause and effect. Using Risk Analysis, convert Uncertainties to structured Risks

- Complexity: situations have many inter-connected parts, which contain Constraints and Variability that can interact dependently, independently and inter-dependently, to affect outcomes and increase Uncertainty. The more complex the situation, the more difficult it is to analyse, given the volume of data and information available for decision making

- Ambiguity: The lack of clarity about how to interpret a situation, caused by vagueness about principles, terminology and definitions. This leads to misunderstandings, due to information being incomplete or inconsistent about the preparedness and potential responses to events

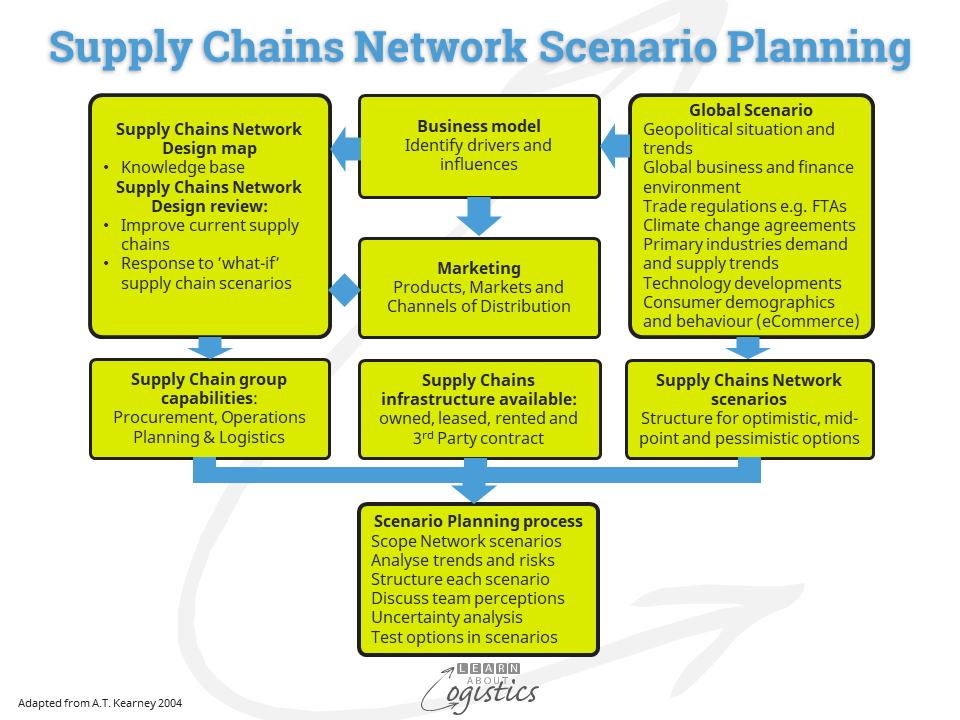

The diagram illustrates the Scenario Planning process for an organisation’s Supply Chains Network:

Scenarios will identify factors that cannot be forecast, planned and controlled. To enable a reasonable assessment of the likelihood and consequences of success or failure for selected options, sufficient information must be available from the Supply Chains Network Design base data. The assessment is done using decision tree diagrams, risk analysis and discounted cash flow (DCF), to provide comparative pictures of possible outcomes for the scenarios.

About five supply chain scenarios should be developed to form decision tree diagrams for subsequent risk analysis. The scenarios use data from the Supply Chains Risk Management analysis, discussed in the previous blogpost. The scenarios will range from optimistic to pessimistic and consider:

- Demand changes,

- Supply base (identify critical items) location, availability and capacity

- Transport infrastructure, mode options, availability and capacity

- Facilities and equipment affecting capacity or inventory

- IT and communication failure and cyber security attack

- People availability and skills

The added factor for a Supply Chains Network is disruptive events in one or more countries, industries or companies (especially at tier 2 suppliers and below); these can randomly affect supply and demand patterns and supplies to your business. The inter-dependent connections provide the unknown and emergent results within a ‘complex adaptive system’ that is your Supply Chains Network.

Options can then be applied to each scenario. Examples are:

- Change the inputs and outputs supplied in the Supply Chains Network; base data, or from other sources

- Expand, contract or postpone operations

- Investment for future opportunities

- A pilot or test project to consider the viability of an approach

- Phase an implementation to conserve resources

- Terminate a project or strategic direction

- An initial selection is modified by another option

Scenario Planning workshop

Scenario Planning is a (preferably) two or three day residential workshop, using an external facilitator, to ensure that discussions do not default into near-term benefits and costs. There are about 12 participants from the supply chains group and other functions, formed into three teams to develop scenarios, identify options and assumptions and evaluate their risks. Software tools developed for the Supply and Operations Planning (S&OP) process can be used, as both require a similar requirement for quick data manipulation within scenarios.

Examples of questions that could be considered, depending on the impact of a scenario:

- supply chains value perception by customers and consumers

- insourcing of production or distribution, on or near-shoring of production; reverse logistics,

- logistics services and contract manufacturing that should be provided to the organisation

- vulnerability of material and intermediate items; concentration of suppliers; price fluctuations and trends

- reliance on hub ports and logistics hubs in the movement and storage of items through supply chains

- infrastructure needs and locations at corporate, at 3PLs and other Logistics Services Providers (LSP)

- extent of data, information and knowledge sharing with external parties

- technology requirements, availability, selection and implementation

- supply chains organisation structure – domestic, regional and international

After evaluating the range of scenarios, a scoping document can be developed. This will identify possible alternatives to the current supply chains, such as: suppliers, routing through transport points, storage locations, supply chain organisation structure and indicative time and costs for implementation. The biggest challenge is then selling the ‘solution’ to your CEO and senior executives.