Why are you not using S&OP?

In business, we live (and die) by financial results. The Profit & Loss and Balance Sheet tell us the financial result of our actions for the past period(s). My question for clients is why financial budgets, with all their defects, is the only tool used for looking forward.

For more than 30 years, Sales and Operations Planning (S&OP) has been the tool of choice for organisations to implement a structured planning methodology. Yet few organisations use the tool; instead relying on budgets, with each function planning its own activities. The question is why and what should be done to improve the likelihood of a successful S&OP implementation.

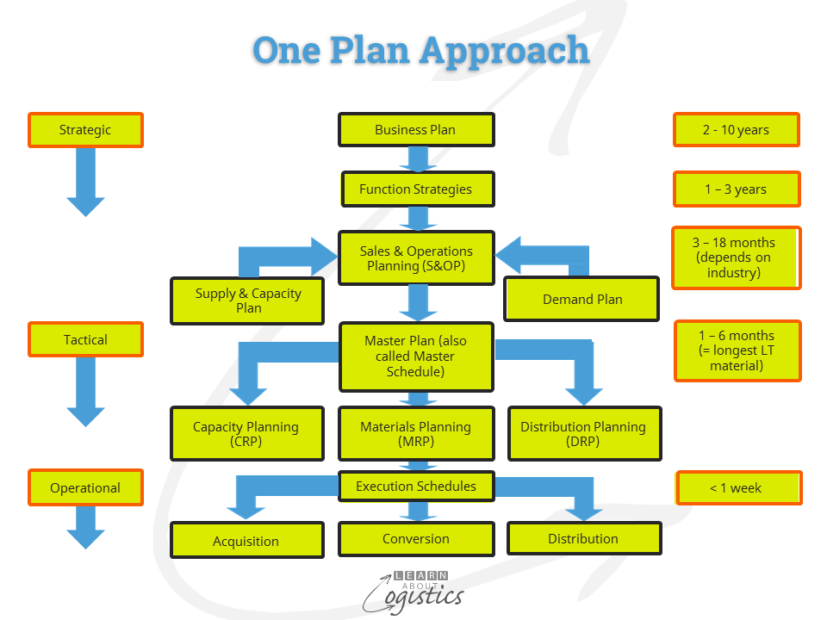

The question of why is mainly due to lack of knowledge and therefore confidence. Business courses at universities and colleges rarely include the topic of S&OP in business or operations planning. Executives are therefore not comfortable with a ‘new’ approach and are often reluctant to seek out information in case they are seen to be ‘not in control’. Yet S&OP should be the ‘hub of the business’, the core of the One Plan approach that balances the conflicting interests of functions.

Requirements for S&OP

Based on my successes and failures in working with clients to implement S&OP, I have learnt some absolutes that are required before going down the implementation path. The first is for the senior Logistics professional to sell the benefits of S&OP to senior management and most important, include the P&L responsible manager, be they the site manager, general manager, country manager or region manager. Before getting into details, managers must realise that a successful implementation can take up to three years for S&OP to be accepted by the team as ‘the way we do business around here’. Until there is buy-in from the P&L manager, any other action has little value. If you think a consultant will help, employ them after the buy-in.

S&OP is a structured planning process, with the objective to improve the balance between market demands, the organisation’s resources and the supply of materials and services. Typically, a discussion about S&OP is focused on organisations that make and distribute products. However, the principles and process are just as applicable to businesses that import products, contract out their operations or sell logistics services. S&OP can be the planning tool used throughout a supply chain – it is as applicable in planning a loading terminal for commodity materials or a shipping container park as it is for planning a product based business.

Roles and responsibilities

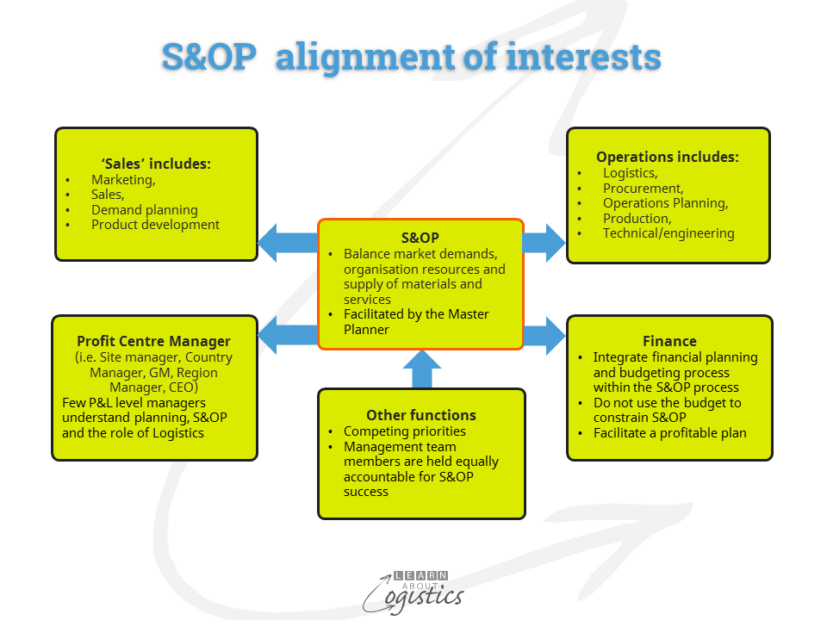

S&OP is cross-function, therefore understanding who will be involved in the process and their responsibilities is vital. As shown in the diagram below, the term ‘sales’ involves all those on the demand side of the business. Operations includes all functions that work to supply products and services for sale. As discussed, the P&L manager is an important element of the process and following their buy-in to adopt S&OP, they must gain support from the executive group. This requires addressing issues concerned with power and status and the likely lack of understanding about S&OP and its role in the business. Specifically, support is necessary to ensure there is a recognition of balance between the ‘sales’ and ‘operations’ parts of S&OP.

Finance has a core role; it is to evaluate the proposed plans on the basis of cash flow management and profitability. However, S&OP is not a budget element; it must be accepted that the budget should never constrain the S&OP, although it can be an input into the S&OP plan. Instead, the plan becomes the monthly update to the budget.

Other functions within the organisation are also a part of S&OP, which is the ‘hub of the business’. Functions can have competing priorities, but they must be secondary to achieving the S&OP plan. Therefore all members of the management team must be held equally responsible for the success of the plan.

A part of the buy-in by the P&L responsible manager is the need for investment in planning – both people and IT. Facilitating the S&OP process through the organisation each month and enabling the output of the plan as the input into the Master Plan is the job of the Master Scheduler. To support the process will require competent demand and operations planning specialists who understand the total process and where their role fits. This should incorporate an understanding of scenario planning, identifying constraints in supply chains and applying ‘what-if’ questions, to structure a feasible supply plan.

It has been stated by other commentators that S&OP is 60 percent change management (organisation and culture), 30 percent process management and 10 percent technology. But even though the percentage is small, software applications to assist the S&OP process are not an optional extra. However, this is not an IT project and the implementation can proceed using spreadsheets and a person who really knows how to drive them. At the same time, it must be recognised that an organisation’s supply network is a complex adaptive system which cannot be comprehensively modelled using an Excel spreadsheet.

Because the concept of S&OP has been available, yet not widely adopted, it has influenced some consultancies and academics to make ‘improvements’. The main activity appears to rename S&OP as ‘Integrated Business Planning’, ‘Sales, Operations and Inventory Planning’ and ‘Sales and Inventory Optimisation Planning’. However, the underlying principles and processes have not changed, so I am staying with S&OP.