Risks when relying on the Cloud

Data and information have value, so organisations need to ideally own, manage and control their supply chain data and information. But this can be a challenge in a Cloud based IT world.

The continual message about ‘partners’ and ‘partnerships’ in business can hide the fact that suppliers are in business to make a profit. The more typical business objective of Cloud based IT application providers is to acquire and monetise data and information – called ‘harvest and hoard’.

Therefore, in contract negotiations for Cloud services, Procurement must identify the balance of power and dependency between the parties. While there are benefits in using the Cloud, there are also risks at three levels when relying on the Cloud – data, information and knowledge.

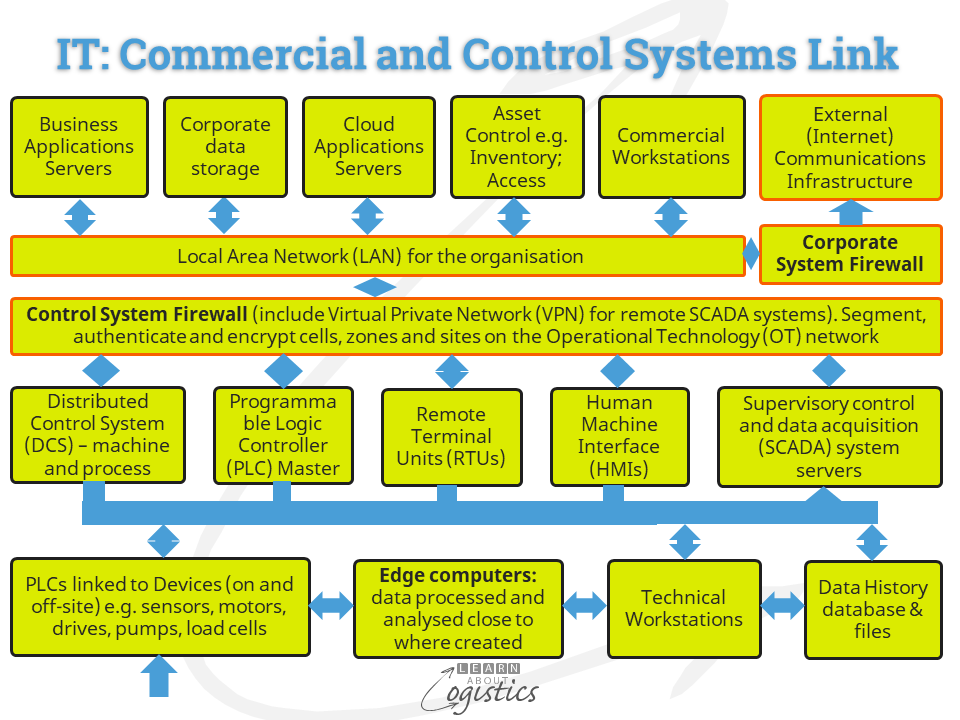

Raw data in the physical aspects of supply chains in your business is collected across two areas:

- assets (typically connected sensors attached to equipment communicating in real-time, increasingly via the Industrial Internet of Things (IIoT)

- the movement tracking and storage of items (materials, WIP and finished goods); also, the condition monitoring of items using IIoT devices

Through the use of applications, the data becomes information – an input for planning supply chains. To improve planning requires knowledge gained from the analysis of information and data. The question is, which organisation should manage these tasks – the brand owner or an IT services provider?

Manage data and information

In an ideal situation, data and information inputs for planning supply chains will remain inside your business. However, additional knowledge can be gained from detailed analysis of the data and information supplied by external services. This is because elements of Artificial Intelligence (AI), such as Machine Learning and Neural Networks, are more likely to be developed inside specialist service organisations.

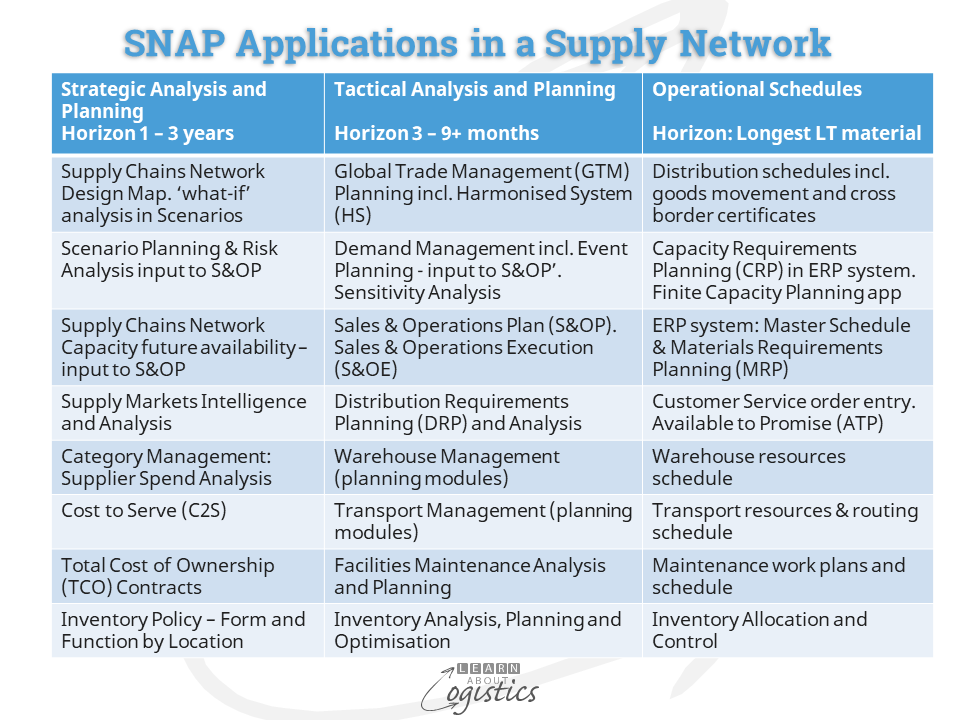

The table identifies a number of SNAP applications. Identify those applicable in your business as either planning or analysis.

A viable scenario for businesses to better own, manage and control their information could be enabled in the near future by three technologies. These are not new, but the growth in data volumes and communications capability have combined to make their combined implementation possible. The technologies are Edge computing, 5G communications and Data Visualisation.

Edge computing

Two terms are used regularly to define Edge computing needs:

- Bandwidth: the amount of data that can be transmitted in a given amount of time. Bandwidth controls the number of possible device connections and enables high-bandwidth applications, such as video

- Latency: the time taken for a signal to be delivered from a device to a computing capability, analysed and a response provided. Low latency is required where fast data analysis and response are critical

The projected increase in the number of IIoT devices will produce an extreme amount of data. However, current data centres, which may be located thousands of kilometres away from where data is generated, cannot process the volume of data with acceptable transfer rates and response times.

Where the requirement is for real-time processing of ‘instant’ data, generated by sensors, devices or users, computation capability needs to move away from data centres to the edge of the network and close to the devices. This allows local processing and storage of data, with caching of information content for timed forwarding of information to data centres. Edge computing is therefore complementary to the Cloud concept.

The data handling company, Vertiv identifies four levels of Edge computing infrastructure: at the device (e.g. warehouse equipment); small number of servers (e.g. loading docks); small data centre (e.g. a warehouse); mid-size data centre (e.g. multiple warehouses on a single site). According to IBM, the need to connect devices, employees, suppliers and customers in a decentralised environment will require three types of Edge computing communications: IIoT Edge; Cloud Edge and Mobile Edge using 5G communications.

5G communications

The standards for 5G define three classes of service over different frequency ranges: low frequency; medium frequency and high frequency. The higher the frequency, the faster the data transmission; but high frequencies are more difficult to implement. The initial implementations will therefore be focussed on low frequency applications which can be implemented on the existing telecommunications infrastructure. Medium and high frequency standalone 5G networks will be deployed by the telecommunications companies over the next few years.

When this occurs, 5G services will be enabled that run on Edge servers, located close to devices. These are called ‘cloud-native micro-services’. This will allow for at least two types of 5G to be provided:

- When low power consumption is required, but low latency and high reliability are not critical. An example is where large numbers of IIoT devices talk to each other and to Edge computers, such as at a tank farm equipped with sensors e.g. flow meters and load cells

- When low latency and high reliability are essential. IIoT devices that require data for 30 seconds or less, with a response time of under 10 milliseconds. An automated distribution centre is an example.

As 5G is introduced, Wi-Fi 6 will also become available. This is about three times faster than Wi-Fi 5 (also known as 802.11ac) and also able to communicate with more devices. However, because high frequency 5G has a lower latency than Wi-Fi and supports more devices within a small area, it will likely be the preferred option for industrial (including logistics) environments. However, both technologies can be deployed to address different outcomes.

At the other end of the speed scale is the 0G (Zero Generation) network. This is a low-bandwidth wireless network designed for basic, low power and low cost IIoT devices to connect via the Internet. These send and receive non time-critical small messages over a long distance. For example, use in condition monitoring (temperature/humidity/time) for short shelf-life items in containers and trucks.

Graphic Visualisation

Bringing Edge computing and 5G and supply chain professionals together is the database technology for graphic visualisation. This is the presentation of data and information using visual elements of maps, charts, graphs etc. to help in the analysis of data and understanding of patterns, trends and outliers.

These applications should also enable Logisticians to graphically analyse and view the nodes, links and interdependencies between all parties, locations and assets in their supply chains network.

When readily available and fully implemented, these three technology approaches will assist supply chain planning and operations, while reducing the risks concerned with ownership and control of information. However, they will only provide value when supply chain teams are knowledgeable of and using supply chain principles. Technology alone will not overcome your challenges.