Actions in response to COVID19

In general, people, including those within businesses, take little notice of future events that are rare, even though the consequences may be catastrophic. With COVID19, governments were warned for decades about the threat of viruses (SARS, MERS etc.), but were unprepared when the disease appeared. People also quickly forget about the community effects of past events and that includes businesses and entities in their supply chains.

After COVID19, there will be different events that could affect or even disrupt supply chains. Then, the likelihood of a new pandemic or other major disaster, with their potential consequences on supply chains will recede. From this comes a likely scenario that after COVID19, many businesses will revert to ‘the same old way’ of doing things.

Articles written by consulting firms provide an indication of responses within their client base to the current pandemic. For example, Accenture reported in their survey that the top three actions by companies were: ordering supplies earlier; creating contingency plans and restructuring supply chains and inventory processes. IDC takes the technology path, stating that “By 2023, 50 percent of all Supply Chain forecasts will be automated using Artificial Intelligence (AI)”.

The IDC statement is not plausible for a relatively new technology. The Accenture report indicates that managers do not understand the ‘lead time syndrome’ effect of ordering earlier; while contingency plans and restructuring are signs that management is ‘doing something’, but to what end? A different approach is to recognise that the risks of small and large disruptions to supply chain will continue and therefore have a process to manage that scenario.

Risk of disruptions to supply chains

The current supply chain risks with COVID19, geopolitical tensions and climate change indicate that risks to supply chains will continue to be present and are likely to increase. Considering health; about five new diseases emerge each year; some serous, others not so serious. A recent analysis of blood samples from bats located around the world, reported that about 3,000 coronaviruses were identified, which have the potential to be transmitted to other animals and then onto humans. Given the rate at which natural habitats are being destroyed and the affect on wildlife of humans, the risk of a future virus pandemic has been modelled at 50 percent chance at any time within the next 25 years.

Natural disasters in 2021 had insurance losses that were one third higher than in 2020 and the trendline indicates an increase. The influence of Climate Change on the rate and severity of floods, fires and winds will continue to increase. Geopolitical tensions and economic nationalism are providing unwelcome news for those businesses using ‘critical’ materials obtained from only a few locations. Also, the ‘chokepoints’ along global shipping routes that are potential disruptions to supply chains in the event of disputes between countries. It is therefore unwise for your business to not plan for risks of disruptions in supply chains.

A process for planning supply chains

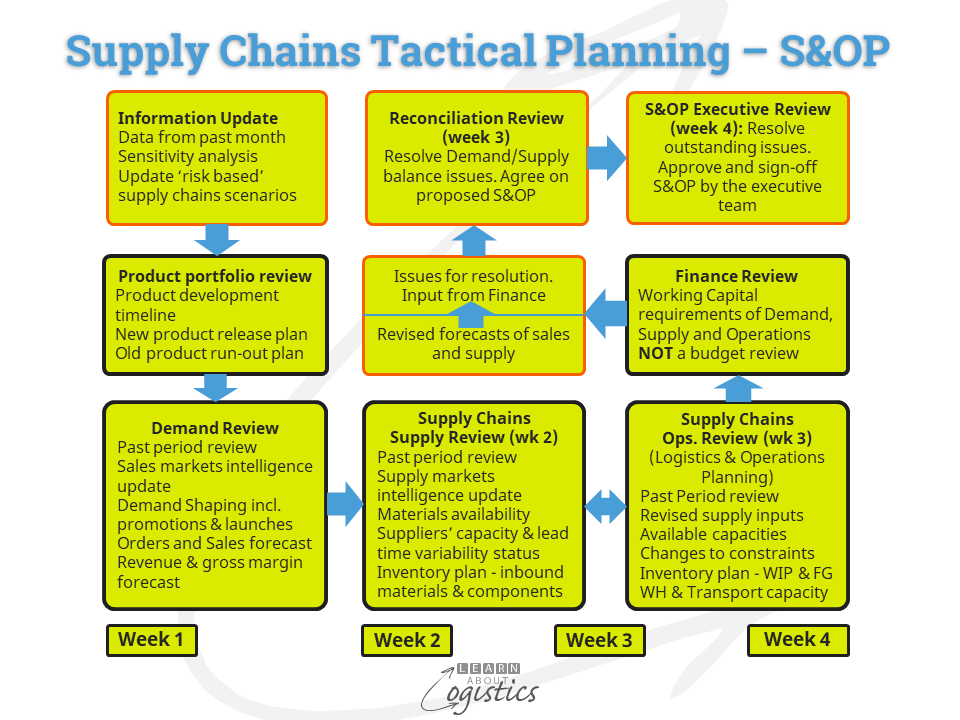

The annual budget is insufficient to plan Operations, as it is designed to inform external stakeholders (shareholders, banks etc.) of the future financial situation in the business – it is not designed as an ongoing management tool. However, a planning process does exist; it is called Sales & Operations Planning (S&OP). The process is applied through eight steps shown in the diagram:

- Information and data updates commence the monthly process

- Review planned changes in the product portfolio by Marketing (product portfolio review),

- Assess demand over the planning horizon and plans to shape demand by Marketing and Sales (demand review),

- Assess the supply situation and planned inventory (form and function at locations); facilitated by Procurement in the Supply Chains group (the supply review),

- Assess the operations capability and planned work in process (WIP) and finished goods (FG) inventory; facilitated by Operations Planning (operations review)

- Review the working capital, cash flow and profit changes of the proposed plan; by Finance (finance review)

- Review the forward plan for supply chains and reconcile gaps in demand/supply by function heads (reconciliation review) and

- Present the provisional plan and unresolved issues to the senior management team for agreement and approval, Ensures the plan is aligned with current organisational objectives (S&OP Executive review)

The steps occur each month, but the review meetings are short – with practice, they become limited to one hour each, because attendees know the format and the data required to be presented.

The objective of S&OP is to improve the balance between expected future demands for the organisation’s products and services, the organisation’s internal resources and the supply of purchased or intra-company provided items. Also, that decisions from the S&OP process can be financed. The S&OP review process enables all in a business with a ‘need to know’ to be involved in decisions and planning concerning their organisation’s supply chains:

- ‘Sales’ – the groups and departments on the demand side of the enterprise. It includes: Sales, Marketing, Product Development and Demand Planning

- ‘Operations’ – the functions that supply products and services for sale. It includes: Procurement, Operations Planning and Logistics (the supply chain group); Manufacturing/production/operations and Technical/engineering

- In addition to senior Sales and Operations executives attending the Reconciliation and S&OP Executive reviews, there will be representatives from Finance, IT and HR/Personnel

- Facilitating the S&OP process is the senior planner, located within Operations Planning

- The chairperson for the S&OP Executive review is the Profit & Loss (P&L) responsible manager (division, country, site etc.). As the focus and needs of individual functions differ, the chairperson must ensure a balance between opinions and the perceived power and status of each discipline. The objective is for the executive group to agree and sign-off an achievable plan

S&OP is a structured tactical process for planning supply chains over the medium term – typically in the range of 18-24 months (excluding the ‘freeze’ period for the current plan), but it can be from 4 months, depending on the type of business. For S&OP to be effective in an organisation requires a concentration on both people and process. Importantly, S&OP is NOT a software driven process. However, the process will be improved with the use of specialist software that assists with analytics, building scenarios and answering ‘what if’ questions.

It is also important to recognise that S&OP is not:

- The strategic business plan

- A budget review: S&OP is a planning process. Budgets are an annual financial positioning exercise. S&OP must not be constrained by the budget; however, decisions from S&OP can be an input to budget updates

- A weekly or bi-weekly Operations meeting concerning performance

Any process that has a structure, can be accused of being rigid in design and not responsive to evolving economic and business situations. As a medium term planning tool, the S&OP process requires a structure to work within, but the approach and contents must be flexible, but that is for next week.