Strategy for changing your supply chains

Supply Chains are not managed. Instead, they respond to events and decisions at each Node and Link in each supply chain. A response is therefore ’emergent’. This requires that functions within your organisation’s Supply Chains must respond to emergent situations and adapt their approach to the affected supply market.

This adaptability must extend to the development of strategies by each discipline that works within the Supply Chains. As discussed in the previous blogpost, strategy is required at two levels:

- The strategic plan, which addresses the next two years for operating and improving the current supply chains and associated functional departments

- The strategy which addresses the next five years for changing elements (internal and external) of the Supply Chains Network that influence your organisation

Whereas the short horizon of the strategic plan enables a detailed action plan for operating and improving logistics, the strategy for change must be more general in scope. For the Logistics strategy, the main requirement is to identify the internal processes and external influences on logistics that require a change to occur. The timeline and approach to the change is not explicitly defined, but it identifies the research and/or trials required to better define the approach. When the most effective approach is agreed, the action required is transferred to the short-term strategic plan for implementation in defined stages over the next two-year horizon.

Many commentors have identified that a major challenge for businesses is complexity of international and domestic supply chains. How things are done (or thought to be done) affects the systems, processes and thinking by people. The overall aim for your Logistics Strategy should therefore be to reduce complexity and become more effective.

What is your organisation’s driver of complexity? It may be ‘market driven’, which by default means ‘Marketing department driven’, to satisfy each perceived market segment. Alternatively, a business can be finance driven or engineering products driven or others. These drivers are not necessarily bad and may have developed with the best of intentions; however, over time they build their own complexities. For Marketing there are ‘new’ product introductions, product line extensions and promotions, all of which can adversely affect logistics.

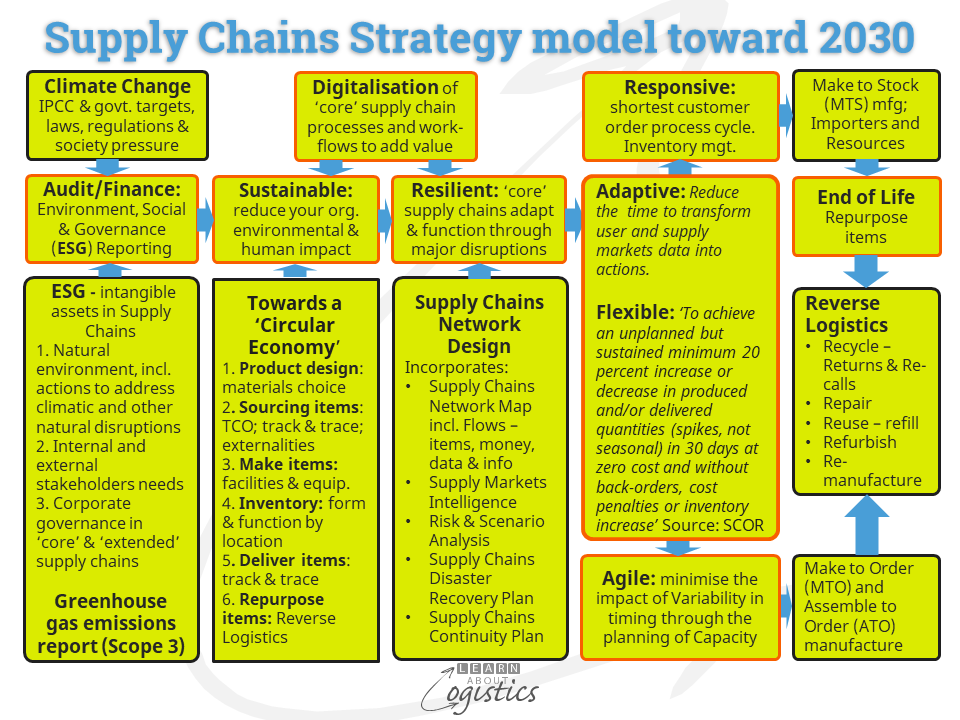

The diagram shows the important terms for change to supply chains that your organisation needs to consider and the documentation that support and informs the actions. The terms apply equally to the Logistics, Operations Planning and Procurement strategies:

- Sustainable and Resilient, supported by Digitalisation; these approaches can enable a business to be Adaptive and Flexible.

- If your business has inventory management as a core feature, it needs to be Responsive, with short order process cycles.

- If your business is ‘make to order’ or ‘assemble to order’, it needs to be Agile to minimise the impact of Variability in the timings experienced through supply chains.

Steps in strategy development

Developing the Logistics strategy for changing the supply chains requires the objectives to be identified. For example, if the aim of complexity is to be reduced by having ‘connected’ and ‘aligned’ Supply Chains, the logistics (and possibly Operations Planning) strategic objectives could be:

- Define how the customer experience can be improved when the organisation has ‘connected’ and ‘aligned’ supply chains

- Establish a standard definition for the organisation concerning the supply chains, their role in the business and the proposed structure of the Supply Chains group. An example of definitions is the meaning of ‘end to end’ supply chains. Learn About Logistics considers that it extends from the mine and farm for raw materials through to the end user of the item. However, a recent article defined ‘end to end’ as between ‘fabrication and the customer’! It is best to avoid using buzz words and terms that could be out of fashion within twelve months

- Establish the extent of alignment required between functions for the supply chains to be effective (identify the required levels of co-operation, co-ordination and collaboration)

- Identify the expected Visibility required through the ‘core’ and ‘extended’ supply chains. Visibility is defined by the Flows of items, money, transaction data and information through the supply chains. Understanding Flows enables Logistics to re-focus its strategy from a functional view to a flow perspective. This approach can change how a business will operate and so takes time and effort to implement

- Identify the extent that data should be used through the organisation’s ‘core’ supply chains – from the organisation to Tier 1 customers and suppliers. For the dissemination of information, define how ‘one version of the truth’ will be accessed and used by employees, customers and suppliers. Also, identify the actions required to ensure data accuracy and the cybersecurity initiatives required within logistics to protect data accuracy

- Identify the extent that the ERP backbone should be supported by specialist Supply Network Analysis and Planning (SNAP) applications. These will access base data from the ERP backbone, complete their planning and analysis tasks and send the solution back to the ERP backbone for consolidation and action. Note that a business with an installed (but is it correctly implemented?) ERP system is not already ‘connected’ or even ‘integrated’ – there is much more to do.

The core functions of supply chains are Procurement, Operations Planning and Logistics, but there are also the support functions of customer service and maybe supply chains focussed finance, legal and IT. All these functions may report through different organisation structures; however, an improvement is to have at least the core functions report to a Supply Chains manager or director. This structure enables a focussed and guided approach to thinking about the organisation’s current and future supply chains and the strategies required for improvement and change that will benefit the business, not just an individual function and a financial bonus.

The strategies for Logistics, Operations Planning and Procurement, should be consolidated into the Supply Chains group strategy. This strategy is enhanced due to the individual strategies being informed, then enabled by knowledge of both the core supply chains that interact with the organisation and extended supply chains that can influence the core supply chains.