Threat to Outbound Logistics.

For most businesses, internal Logistics is where supply chain professionals maintain the balance between inbound and outbound Logistics. But what success can be expected from working independently from other functions?

Inbound Logistics can experience change caused by the effects of decisions by suppliers, service providers, natural emergencies and external (i.e. government). However, an increasing threat of change is to outbound Logistics via the growth of retail sales in the eCommerce channel of distribution.

A recent report by Fitch Solutions considers that by 2022, eCommerce in Asia will be the largest in the world; increasing by nearly 50 percent from expected sales in 2019 (with China having a share of more than 70 percent). Even if these forecasts are optimistic, for affected businesses, change in the management of their internal Logistics will be critical, but the areas in which improvements can be achieved are also important.

The eCommerce induced pressures of shorter lead times and quicker deliveries of products will progressively change expectations about lead times of many supply chains, irrespective of their reliance on eCommerce channels of distribution. For example, visibility through supply chains is being promoted as a means to achieve shorter lead times; However, while co-operation with other organisations in your supply chains or industry is beneficial, it should not be relied on as the solution. Commercial realities mean that:

- customers and suppliers are reluctant to share critical data and the ‘sharing of risk and reward’ (the meaning of partnership) happens only in rare situations. The term ‘partnership’ as generically used in articles and company reports has no meaning;

- software suppliers have little incentive to provide inter-operability between supply chain commercial and technical applications

For these reasons, success for organisations can more easily be attained through improving their internal Logistics, in both planning and materials handling techniques. But, an organisation cannot change all aspects of its business as one event – it will take time. So, while change occurs to outbound Logistics in response to market signals (i.e. demand pull), inbound Logistics must structure an effective buffer to supply what is forecast to sell (i.e. product push). The buffer is inventory – structured through forward planning and the response of internal processes and systems to orders and summarised as Availability.

Value Chains

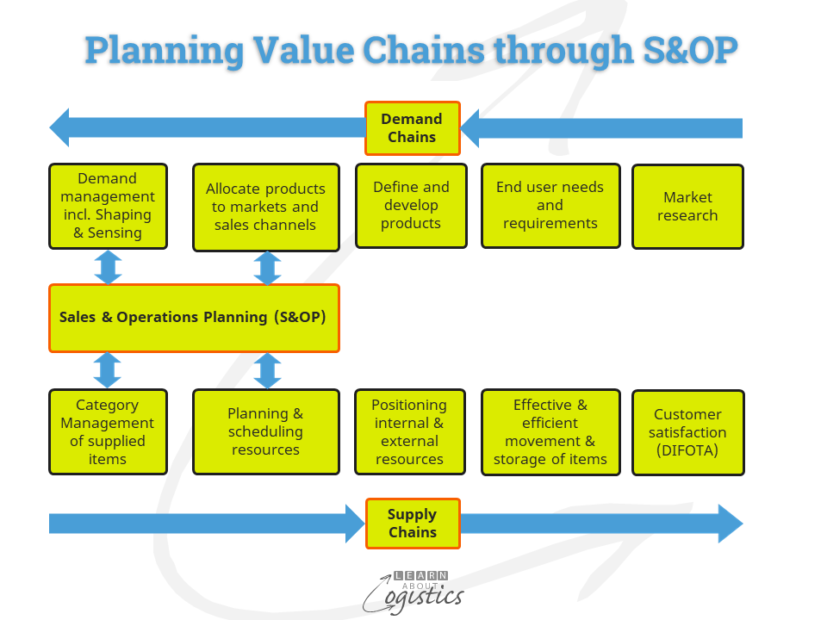

The diagram below illustrates the structure of Value Chains – the flows through Demand and Supply chains.

Demand Chains are the responsibility of Marketing and the final link is Demand Management, which includes Demand Shaping. This comprises plans and actions to increase customer and/or consumer demand for the organisation’s products and is achieved through new product releases, current product upgrades, product promotions, price reductions, commercial buyer (that is, trade) incentives and sales force incentives.

Sales & Operations Planning (S&OP) is the mechanism by which information about future demand (Demand Plan), is matched with information about future supply capability (Resources Capacity Plan) and where decisions are made about how to harmonise demand and supply. The previous blog identified areas for initial attention to improve the S&OP as:

- Demand Shaping to improve the pattern of customer and/or consumer demand

- Inventory positioning in the organisation’s supply chains, including Postponement

- Decoupling points interface, between ‘demand pull’ and ‘product push’ in product and materials flows

Demand Management

Some of the challenges associated with developing a Demand Management process for an organisation and which management can believe are:

- Development of the Demand Plan – a best estimate of market demand (and corresponding sales) and profitability for the products on offer, using inputs from Demand Shaping and Demand Sensing. However, Marketing can be under pressure (personally and financially) to modify the Demand Plan – referred to as ‘managing expectations’ (and also known as ‘sandbagging’)

- The Demand Plan is mainly determined by the organisation’s financial objectives, to assure investors that financial targets will be met, with little reference to market demands

- Uncertainty in the organisation and through the Supply Network can increase due to uncoordinated implementation of Demand Shaping programs

- Accuracy and variability of feedback (both structured and unstructured e.g. social media) from the sales channels (called Demand Sensing). This assists decisions about response to the success or otherwise of individual marketing programs

- Demand Amplification through the supply chains. This is when a small change in demand by end users in a supply chain can cause a substantial change in upstream demands; due to the influences of: demand plan forecasts; order batching; price fluctuations and order rationing

The Demand Plan provides forecast concerning product and/or services sales by period, the likely pattern of sales take-up, probability of success and likelihood of reliable feedback. This allows the established and new programs to be allocated sufficient Logistics and operational resources to meet the sales objectives. However, a more accurate Demand Plan is of no additional value to an enterprise unless it is part of a formal, disciplined process for decision-making. That process is the Sales and Operations Plan (S&OP).

Providing Availability is the role of Logistics. To provide initial improvement in your current S&OP or to assist the introduction of S&OP, address Inventory Positioning and Decoupling points interface. These will be discussed in the next blog.

The challenges noted above for Demand Management provide an indication of the change management efforts required in an organisation to change corporate culture and the associated processes and systems to meet an emerging external challenge. Supply Chain professionals need to be at the heart of these changes, as improving their organisation’s Supply Network is to their direct benefit. To ensure an effective S&OP process, work with executives from Marketing, Finance, Operations and Human Resources – offer co-operation and sell the advantages of a responsive business.