Views on the future

Although the COVID 19 infection rate continues to rise in many countries, there are moves to open economies. This has prompted discussions about possible changes to the business models of commercial enterprises.

Helpful input to your thinking about options for supply chains is a recent survey ‘Emerging out of the pandemic supply chain report” conducted by Reuters Events amongst 587 supply chain executives across North America, Europe and Asia. The survey identified three key areas for the supply chains organisation of a business to address: Risk management; visibility through the supply chains and targeted technological investment.

At the same time, investment managers at Magellan Financial Group, an Australian based investment companies that manages $A98b of funds, provided their view of how companies should view the future world. Their revised criteria for investment are that a business must be managed for Risk and be Resilient and Sustainable. If other large investment firms come to the same (or similar) conclusion, share (or stock) prices could be influenced.

Similar opinions from two diverse groups indicates that business strategy and performance measurement criteria will include Risk, Resilient and Sustainable and they will drive the supply chain strategy.

Uncertainty has been built

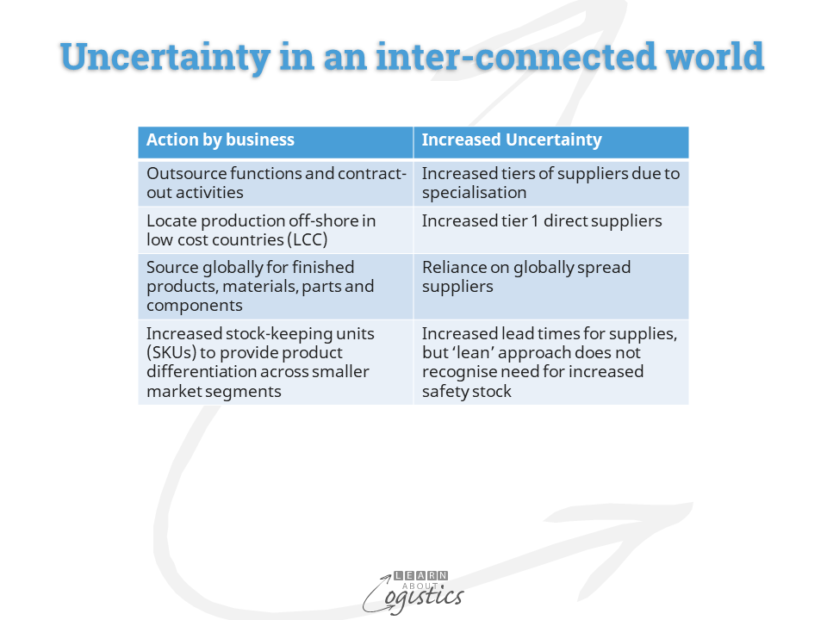

Over the past forty years, changes in investor expectations about returns has influenced corporate behaviour. This has been assisted by changes to country taxation rules, upgraded transport infrastructure and ships, trucks and aircraft, together with improved communications capability. However, the incentives to globalise business comes at a cost of increased Uncertainty.

The eight factors in the table are examples of how Uncertainty can increase through complexity, variability (and volatility) and constraints within your supply chains (and elsewhere in the business). They can interact and amplify each other, which increases the impact on your organisation of supply chain disruptions.

Too often, operational functions are structured to address business objectives in an efficient and least cost manner. As this approach is functional rather than based on material and data flows, it has the danger of locking-in complexity and systemic risk within the supply chains. However, change gets traction when people believe that long term viability factors are strategic to the business and to their jobs – the pandemic is the catalyst for change.

Managing risks is an investment in future events. The greatest risk for an organisation is to be in a reactive mode; responding to events only when something goes wrong (the ‘can do’ approach). Not investing in processes, techniques and technologies to anticipate threats in your Supply Network is a negative, not positive cost saving.

The risks to the long term viability of a business are generally identified as:

- Economic: brand and business value; profitable revenue; reduce the cost of doing business. These can be affected by international and domestic government economic policies and actions (called geopolitics)

- Environmental: climate change and the potential of moving towards a ‘circular economy’ for items

- Industry-specific regulations: carbon emissions standards

- Physical: availability and price of utilities (water, electricity and gas) and their usage efficiency. Renewable energy uptake. Use of eco-friendly packaging

- Social: changing demographics among consumers. The origin of products and ingredients (‘clean and green’). Labour conditions in supply chains. Perceptions about the role of employment.

- Technological: implementing telecommunication technologies. Potential of disruptive technologies

There is an added factor for your supply network. How disruptive events in one or more countries, industries or companies can randomly affect supply and demand – and supply to your business. These inter-connections illustrate the unknown and emergent results within a complex adaptive system – your supply network.

To reduce Uncertainty requires, as a first step, to classify and measure the elements that are risks to the business, then structure a program to address the risks, commencing with those which have a high likelihood of occurring and costly consequences. But, do not forget those with low probability of occurring but disastrous consequences e.g. the current pandemic.

Being Resilient

As the objective of risk management is to avoid not recovering from an event, an initial activity of Resilient is to ensure Business Continuity. To achieve this, your organisation needs the Supply Chain strategy to be both dependable and flexible (that is, resilient).

Dependable: systems and processes within an organisation must be both predictable and robust. Changes in the wider environment, for example capacity constraints, weather and industrial disputes, are overcome without substantially affecting customers’ requirements.

Flexible: the capability to quickly re-structure so that orders of varying volumes, product mix and delivery requirements can be addressed profitably. This requires equipment and organisation structured for flexibility, integrated with a flexible cost and pricing system.

Actions taken to be dependable and flexible within your uncertain Supply Network are:

- Identify areas of vulnerability, then build in flexibility to cope with the impact of unexpected events:

- Increase visibility through your supply chains through ‘track and trace’ IT capabilities

- Increase redundancy through your supply chains

- Specialisation and intense optimisation can make your organisation more vulnerable, because as hidden risks rise, there are fewer options available for a response

- Use an ‘environmental scanning’ methodology e.g. PESTEL, to help identify ‘knowable unknowns’ before they occur

- Establish early warning indicators from demand and supply markets that signal when a situation is different from normal

Being Sustainable

For many business organisations, sustainability has been viewed only as an environmental topic. A sustainable business requires other inputs e.g. knowledgeable and capable people, but the environment is a good place to start.

Factors about sustainable supply chains are:

- Sustainable and Sustainability can easily become another buzzword used in business press releases. The term is meaningless without objectives, targets, projects and ongoing measurement

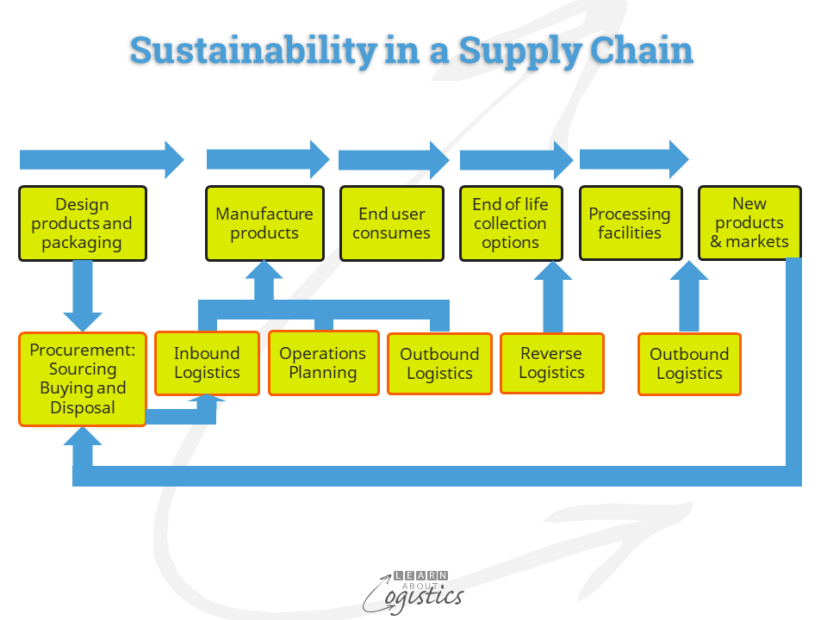

- A sustainability strategy can only be implemented through your core supply chains after the concept has been adopted by the organisation. The board of directors and executive team must agree that the use of materials, energy, water and the generation of waste through the core and extended supply chains will influence the future of the business

- The supply network is treated as a system which creates added value and incurs total costs of ownership (TCO) for supply inputs. This requires a network approach to access knowledge about the most effective practices

- A sustainable future will require a change of mindset from short-term performance e.g. Return on Investment (ROI)

Some factors to consider about Sustainability are:

Procurement – sourcing and buying renewable, recyclable or biodegradable materials as substitutes for new inputs:

- Product life cycle: Identify points in the life cycle when it is cost effective to implement sustainability actions e.g. when re-negotiating a contract for the ongoing supply of a material

- Sourcing: Incorporate evaluation criteria related to materials, packaging or processes to meet sustainability objectives

Logistics has two elements:

- Distribution, warehousing and storage: Reduce the energy and water resources required per unit of sale

- Transport: Evaluate the most effective transport options by mode concerning: density of the product; ‘stowability’ and ‘stackability’; handling; liability and return trip capacity. Factors to consider:

- Future fossil fuel costs affecting freight rates – global politics can quickly change pricing models

- Congestion costs by transport mode

- The emphasis of logistics changes from excellence in physical movement to excellence in data collection, information exchange and analysis

More businesses and supply chain professionals are seeing climate change for what it is – a risk, resilience and sustainability issue (also a business opportunity!). The pandemic is a test run for the future! Start now to build scenarios and undertake analysis of the likelihood and consequences of climate induced events that will affect your business and its supply chains.