Thinking about strategy.

Strategy is a term that concerns actions which alter the relative strength of your enterprise to that of your organisation’s competitors, at an acceptable cost. These actions are different from those aimed at achieving operational improvements. There is not a ‘perfect’ business strategy, but the approach should avoid doing the same thing as the competition, so have flexibility in your thinking.

An influential book of the mid 1990s concerning the development of business strategies was Managing with Dual Strategies by Derek F. Abell. He explained that “Running the business and changing it are not sequential but parallel pursuits… Running a business requires a strategy in terms of defining target markets and attending to those factors which are critical to success. Changing a business in anticipation of how the future will look requires a vision of the future and a strategy for how the organisation will have to adapt to meet future challenges”. He continued “… planning for today is about managing for results; planning for tomorrow is about managing change“.

Although some commentators identify that ‘continuous change’ is the new way of business, in reality, the time taken to get prepared for changing a business model of a currently successful business can be in the order of two to three years. The strategy for running the business will therefore have a rolling horizon of about three years. For that period, the senior executive group will set the Business Aim or Goal and the Business Objectives by which the Aim is to be achieved. The Aim and Objectives are then approved by the board of directors.

Functions develop the Strategic Activities

To meet the Aim and Objectives, the functions will develop a plan for their strategic activities. This is acceptable when functions are designated as silos, but becomes a challenge when a function cuts across a number of other functions. This occurs with an organisation’s Supply Chains, where there are at least seven Elements, but not all may be entities with the full range of activities described and discussed in my previous blog. Even if the Elements are functioning entities, some could be part of another function e.g. Operations Planning within Manufacturing; Procurement within Finance; Distribution within Marketing; all Sales activities within Marketing and Supply Chains IT within corporate IT. In addition, the situation for some organisations is that:

- The elements that should be core within a supply chains organisation are currently viewed with a cost focus. Therefore they operate separately, with little need for strategy – cost efficiencies are the main requirement

- Supply chains are viewed as a cross-organisational activity that is not under management control of any one function. Therefore each function of the business includes their involvement in the supply chains within their own strategic plan

For these reasons, few companies have a strategic plan for their Supply Network – a critical part of the business.

So, the likelihood of the disparate functions involved in supply chains being in any way ’integrated’ is unlikely, whatever IT systems have been implemented. However, the increasing discussions about supply chains may influence the CEO to at least want a ‘connected’ supply chain strategy. The executive responsible for Logistics (could be you) is therefore given the responsibility to consolidate the supply chain elements of all functional strategies of the business into a corporate supply chain strategy. What to do?

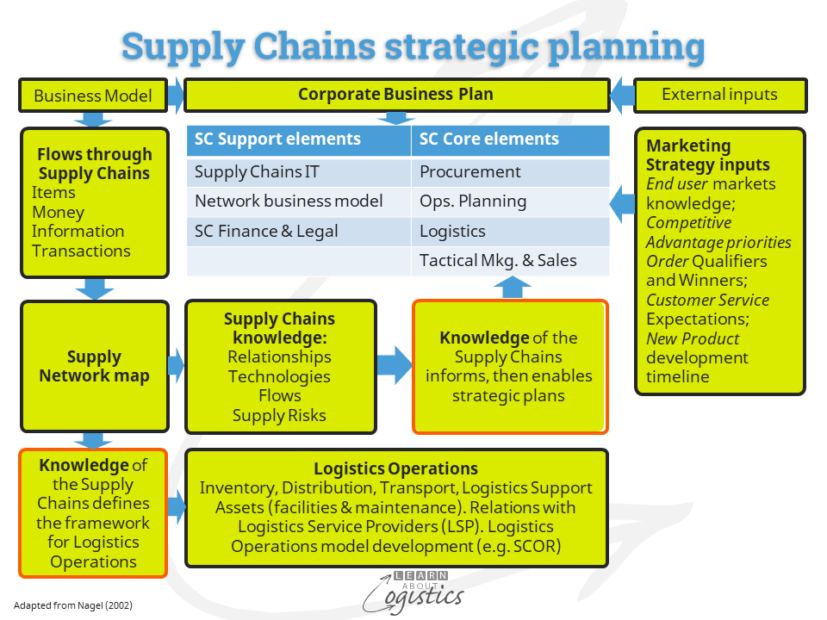

Bringing the message that “the CEO asked me to do this” will not improve the reception by functional managers – preparation is a must. To facilitate all managers ‘singing from the same song book’ requires a ‘mud map’; the diagram below provides such an overview. It illustrates links in the organisation which occur through the Supply Chains; for example, the critical link between Marketing and the Supply Chains.

The red boxes in the diagram contain statements which explain why a ‘connected’ supply chains strategy should be written:

- Knowledge of the Supply Chains informs, then enables strategic plans

- Knowledge of the Supply Chains defines the framework for Logistics Operations

Armed with the above diagram and a script that sells the idea of ‘connecting’ parts of the organisation to generate a Supply Chain strategy, how to proceed? As analysis is the starting point for thinking strategically, the amount of analysis concerning the Supply Chains done (or planned) by Logistics prior to the meetings will indicate the level of commitment to the strategy process. Success at each meeting(s) will enable an expansion of your selling script and improve the chances of successful meeting with other functional managers.

As the distinguishing feature of business strategy is developing a competitive advantage, the first stop is Marketing, to gain their views. However, the strategy meeting cannot be the first meeting with marketing – at a CPG company, I met weekly with the product group managers to let them know what operations were planning and get their feedback – and build trust.