Aiming for perfect orders.

Expectations between customer and supplier can be different, concerning performance through the cycle of an order. A role for Logisticians is aligning the expectations for perfect orders to be delivered.

A common Logistics measure of actual delivery performance for a period (shift or day) is the Fill Rate – acceptable (but not necessarily perfect) customer orders picked and dispatched as a percentage of total orders. Some businesses also identify the Backorder Rate (BOR), which measures the percentage of unfilled orders to total orders. However, the overriding requirement of customers is that each of their orders is a ‘perfect order’.

At your delivery facilities – company operated or outsourced to a 3PL contractor, today may be a good day, with every customer order picked and delivered without a problem; however, will this be the situation every day? Or worse, delivery performance may decline, without anyone being aware. It is surely someone’s fault – with most of the requirements of a ‘perfect order’ the responsibility of Logistics.

The customers’ view of a perfect order means the:

- initial customer order is not modified because:

- particular SKUs are not available

- sufficient inventory of particular SKUs is not available

- deliveries cannot be made when required by the customer

- delivery of the order will be ‘in full’

- receipt of the order by the customer will be at the agreed date and time (‘on time’) and

- all documents (electronic or physical) associated with the order cycle are accurate

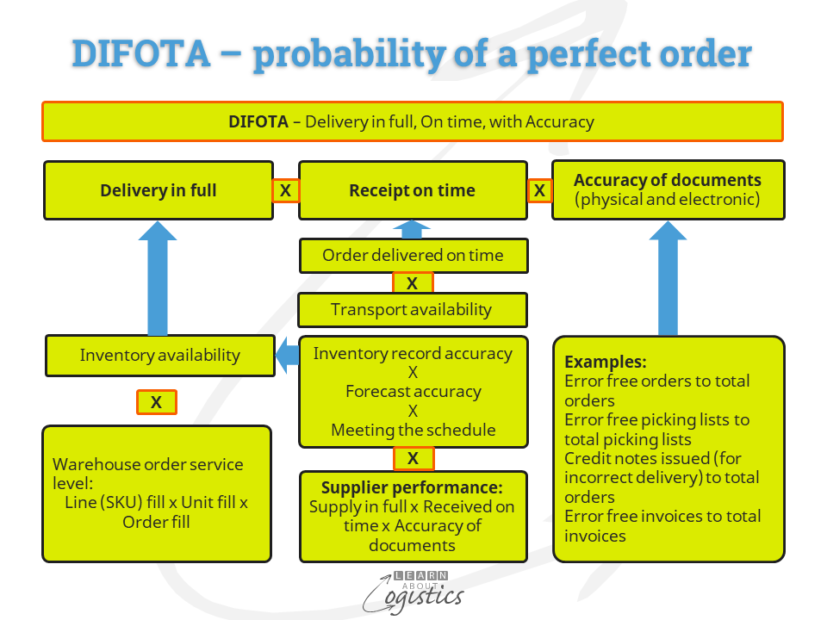

The capability of your business to provide a perfect order is best measured using DIFOTA – ‘delivery in full, on time with accuracy’. An earlier blog, identified DIFOTA as one of three techniques that identify how well the supply chain group will achieve the objective of providing Availability of items for customers. The other techniques are Sales & Operations Planning, which enhances cross-functional co-ordination and Risk Management as the basis for managing Uncertainty.

DIFOTA is not a measure of operational performance for the previous shift, yesterday or last week. Instead, it is a technique to evaluate future performance in providing Availability. That is, it measures at a point in time (end of week or month), the probability of your business achieving a ‘perfect order’. Through plotting DIFOTA results, the trend in future performance is evident, so that action can be taken to correct areas of weakness.

Calculating DIFOTA

The DIFOTA probability measure is calculated through multiplying the three performance elements (in full, on time and accuracy). For example, if each element is calculated at 95 percent, then .95 x .95 x .95 provides the overall DIFOTA probability of 86 percent. This indicates that approximately one delivery in seven could have a problem – and that would be a very good result! However, it is more likely that in your business, DIFOTA could be 50 percent and it is not uncommon to have a DIFOTA at 30 percent!

To achieve a high DIFOTA relies on the performance of subsidiary factors within each element. Working through an example, based on the above diagram (developed by the firm Benchmarking Success in 2002):

Delivery – In Full

- Inventory availability is calculated by multiplying together the four measures of:

-

- inventory record accuracy

- forecast accuracy

- meeting the schedule and

- supplier performance (supplier performance is calculated from the DIFOTA measure for each supplier)

For this exercise, assume that inventory availability is 80 percent.

- Warehouse service level: If orders have 10 SKUs totalling 100 units and 9 SKUs totalling 95 units are picked and dispatched, the performance is:

-

- line (SKU) fill = 90%;

- unit fill = 95%

- order fill = 0%

The Warehouse service level = 85.5 percent

Delivery In Full performance: 80% x 85.5% = 68.4 percent

Receipt – On Time

- For 100 orders, 90 are delivered on time = 90%

- Transport availability: The required transport mode was available when required to move the orders e.g. if 10 trucks (own fleet or 3PL) are scheduled for the period and only 9 were available at required times = 90%

Receipt On Time performance: 90% x 90% = 81 percent

Accuracy of documents

Examples of documents and assumed performance:

- Order entry: The number of error-free orders divided by the total number of customer orders = 97%

- Customer claims: The number of credit notes provided to customers (these are issued for returned orders: wrong delivery address, wrong quantities, wrong time etc.) divided by the total number of orders = 97%

- Picking lists: The number of pick lists without error divided by the total number of pick lists = 97%

- Invoice accuracy: The number of error-free invoices divided by the total number of invoices = 98%

Accuracy of documents performance: 97% x 97% x 97% x 98% = 89.4 percent

In this example, the measure of DIFOTA is 49.5 percent (In full 68.4% x On time 81% x Accuracy 89.4%). This measure is fairly typical for a logistics operation in the consumer packaged goods (CPG) and fast moving consumer goods (FMCG) sectors.

A competitive DIFOTA should be greater than 91 percent. The objective for each of the DIFOTA elements should be:

- Delivery In full = 99 percent, with inventory availability at 95+ percent

- Receipt On time = 99 percent

- Accuracy of documents = 99 percent, with accuracy of order entry at 99 percent and accuracy of invoices at 99 percent

This discussion has approached DIFOTA as one measure. However, an effective Logistics function will segment customers based on the ‘cost to serve’ calculation. Therefore, as the measurement process becomes an integral part of Logistics, DIFOTA can also be calculated by customer segment.

Although most of the factors within DIFOTA come under the responsibility of Logistics, do not under-estimate the time and effort to gain acceptance and approval and to implement the process. Later improvements to the process should be addressed within an overall ‘one plan’, rather than the more typical ‘department efficiency’ approach.

Implementing and improving DIFOTA can result in your business providing a superior level of customer service, which is a competitive advantage of itself – service (and services) are more difficult for competitors to copy.