Procurement and its role.

Selling products and services builds a market and your business; effective supply chains enhances customer satisfaction and increases the profit margin.

Increases in the profit margin requires that flows of items through your supply chains are planned and managed by an effective organisation structure, able to address the improvement initiatives necessary in competitive markets. The structure of a supply chain group for your organisation will vary, depending on the enterprise, its ownership and culture, the industry and local customs and cultural settings. The place of Procurement in your Supply Chain organisation will be part of the thinking.

Procurement is the interface between your organisation and its suppliers and this sets the tone for relationships. Are all suppliers treated the same or do relationships differ, based on the ‘importance’ of a supplier to your organisation? Who approves the criteria for dealing with suppliers and is the criteria objective or based on impressions?

In a competitive supply market and whether Procurement is part of the supply chain group or not, relationships with suppliers are critical to the improvement of your supply chains. Achieving this through a structured approach provides a firm foundation and is called Supply Planning.

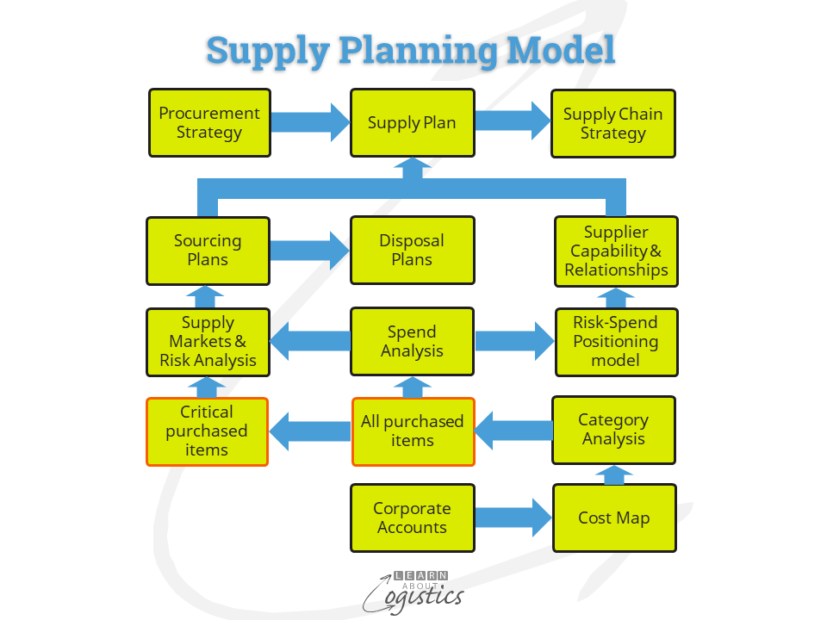

The diagram illustrates the elements within a Supply Plan, commencing with the corporate accounts and, following analysis, provides two inputs to the Supply Plan – the sourcing plans and supplier relationship guidelines. Each of the steps through the model will be discussed in future blogs, to answer two questions:

- What and how much do we buy?

- From whom do we buy and why?

With these questions answered (an exercise not as easy as it reads), it provides a basis for reviewing:

- How do we buy – the process

- How well do we buy – performance measurement

Why is a Supply Plan necessary?

As trade across borders has increased, so buying goods and services on a global basis has become more complex, requiring a more strategic approach to Procurement. Factors influencing this situation are:

- Increasing percentage of corporate income spent with suppliers

- manufacturers = approximately 60 – 70 percent of sales income

- services = approximately 25 – 40 percent of sales income

- Increased percentage of expenditure on non-production (indirect) costs such as marketing, sales promotions, IT and communications and after-sales service

- Organisations buying packages of items (products plus the associated services)

- Continued outsourcing in developed countries of major functions

- longer-term contracts to be managed

- Increasing length of supply chains

- time to market pressures, with decreases in the planning time allowed

- inbound inventory decisions concerning location, form, function and quantity

- Cross-border challenges of:

- duties and tariffs associated with trade agreements

- sourcing from low cost countries (LCCs)

- local content rules

- transfer pricing (with potential legal and tax challenges) between divisions/subsidiaries of a business

- taxation and withholding tax rules

- economic changes in supplying countries

- effects of geopolitical events

- natural disasters and affects on suppliers

- duties and tariffs associated with trade agreements

These factors require the Procurement function to acquire a deeper understanding of the organisation’s supply chains for acquired items and services, which include:

- Demand and supply characteristics through an item’s supply chain, such as variability of demand and reliability of supply

- Mapping the nodes and links for items in supply chains

- Identify vulnerabilities (risks) and volatility (potential waste) in the inbound supply chains

- Develop plans to reduce risks and waste

- Develop measures of performance for risk reduction

Developing a higher profile concerning matters affecting inbound supply chains, Procurement is then able to take the initiative on matters concerning supply. Examples are:

- Engage internal stakeholders with regular supply updates and timely cross-functional meetings

- Work with Finance and Accounting to establish the total cost of ownership (TCO) for purchased items, as an input for sourcing and buying decisions

- Conduct workshops to develop risk contingency plans

- Become the lead adviser in the organisation concerning outsourcing and off-shoring activities

- Provide the lead role concerning implications of various supply scenarios on sustainability

As knowledge is acquired, Procurement is better able to work with other functions in the Supply Chain group, providing inputs to improve measurement of the total cost of ownership and manage risks identified in various supply options.

To address the added responsibilities and knowledge required of the role, Procurement professionals will now require a skill set that contains at least the following attributes:

- The fundamentals of developing a Supply Plan, including:

- analysis of products and services within supply categories

- research of supply markets for products and services

- Supply risk analysis

- Purchasing processes, including the development of negotiation plans

- Marketing and sales principles

- sales process and tactics, including those of monopolies and cartels

- Contract management fundamentals, including the legal framework and development of balanced contracts

- Financial and business analysis processes

- Operational improvement techniques

- the motivation for suppliers’ improvement activities

- Collaborative leadership with larger and broader groups of stakeholders – requires business and personal skills

If it is decided that Procurement will be part of the Supply Chain group, the performance of each function will remain important. The starting point for providing Strategic Procurement is the Supply Plans. This will provide, over time, some of the inputs to the Procurement Strategy document, which is “A change program that positions relationships with suppliers as a core activity of the organisation; with the objective to gain competitive advantage and provide the maximum contribution to corporate profitability” (adapted from Steele and Court 1996).