Customers are necessary in commercial organisations

But what is the collective view about customers inside the business? It is driven by the chief executive, guided by corporate performance measurements that are approved by the board of directors – ‘we behave how we are measured’.

This can result in a mixed message. Companies may promote that they are ‘customer focussed’ or ‘customer centric’ and sometimes even ‘demand driven’; but at heart the focus is on profit maximization.

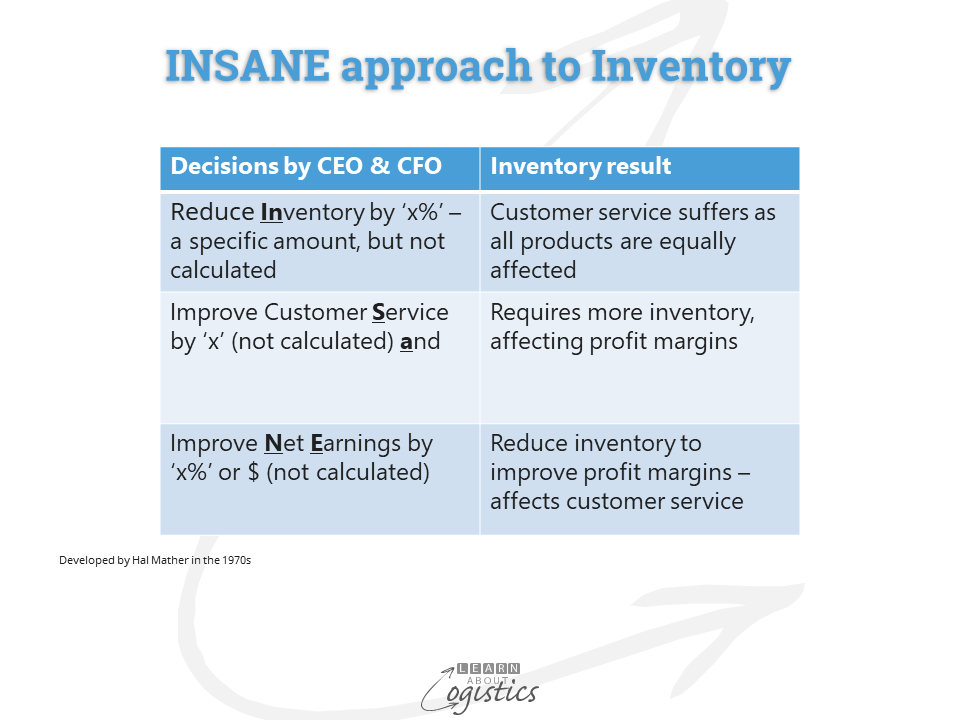

For companies selling goods, a profit focussed business is likely to be ‘driven by the numbers’. Planning of operations is based on achieving budgets; inventory management has the INSANE approach (see diagram below); long production runs for reduced unit cost, and the main disciplines of supply chains (Procurement, Operations Planning and Logistics) are unlikely to be aligned as a group and have a focus on low cost and ‘efficient’ operations.

However, the objective of an organisation’s Supply Chains group is to improve customer service through providing Availability of goods and services. But a business with an ‘efficient’ approach to supply chains is unlikely to be the most effective in satisfying customer demands. For a Supply Chains group to be successful, there needs to be an understanding in the business that serving customer’s needs and being effective and profitable are not mutually exclusive. They are equal objectives.

Measuring performance in financial terms

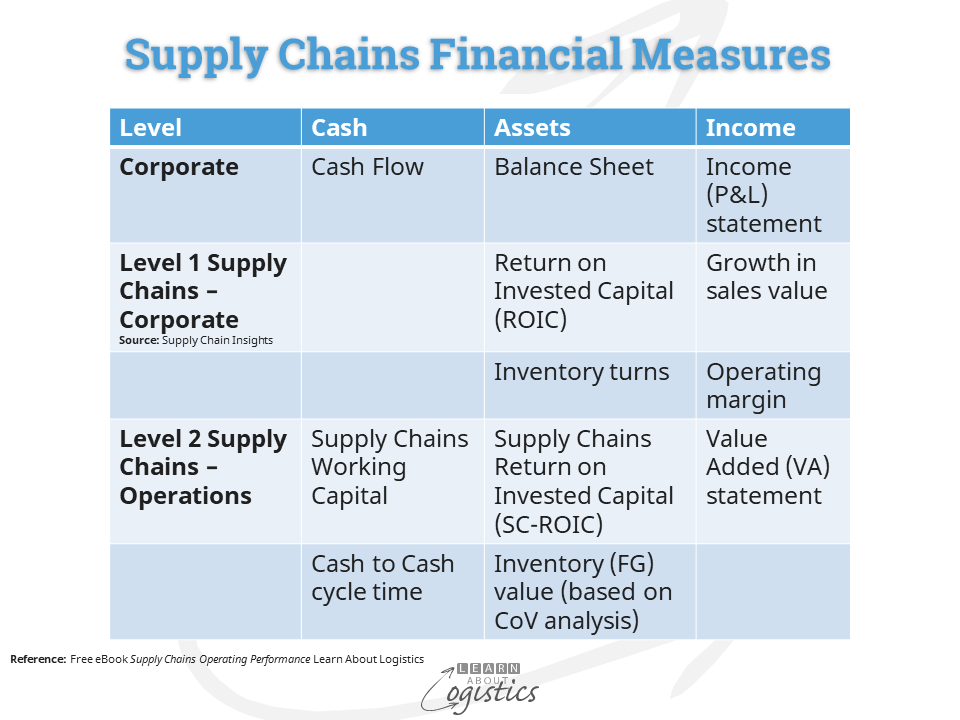

For supply chains to receive sufficient attention as a discipline at the Board of Directors level, financial performance measures are critical. The diagram below identifies financial measures for the Supply Chains group at two levels. Level 1 is the Corporate level, with measurements based on outputs from the corporate financial reports. Level 2 provides measures at the Operations level, which need to be structured from available data.

Supply Chains Working Capital and ‘Cash to Cash’ cycle time can be quickly implemented. The Supply Chains Return on Invested Capital (SC-ROIC) and the Value Added (VA) statement require co-operation with Finance to enable the structure and data access. The finished goods Inventory value is based on the CoV analysis, which Operations Planning must implement. To achieve a high level of performance in each of these measurements requires a cross-functional alignment of purpose and co-operation.

Performance in providing Availability

A brand is a collection of experiences and associations connected with a product or service, which includes customer experiences associated with Supply Chains. It is more than the effort that Marketing employs. However, responding to customer demands is not a single functional process; it ideally requires the connection and alignment of functions as the organisation handles Flows of items, money, data and information.

The order qualifiers and winners for each product group in a brand and the Logistics strategies are dependent on where in the supply chain the organisation is positioned and the size and weight of the items, although many of the input materials could be the same. This influences the Procurement strategy. As qualifiers and winners change over time, Marketing/Sales and the Supply Chains group need to realign strategies in response to changing phases through product life cycles and in anticipation of market or industry trends.

A ‘Customer Care’ approach is an attitude that customers have a real value. This attitude is built into relations with customers, which since the 1980s has the title of ‘Moment of Truth’ – when a perception of the business is formed by customers and their staff. Each ‘moment’ lasts a short amount of time, but requires:

- the person who responds to a customer contact is responsible for the satisfactory completion (maybe through others) of the engagement – questions are not ‘handballed’ and forgotten;

- promises given are fulfilled in the stated time and

- staff are trusted to use their training and initiative to satisfy customer requests without reference to managers

The Moment of Truth policy supports the Customer Care approach, because it is evidence for customers of the organisation being Reliable. When customers have confidence with obtaining Reliability, they are more willing to discuss their needs, for example: low cost, speed of delivery, flexibility with orders and timing or quality of the process. Customer service policies can then be better defined in terms of type of delivery service, lead times, minimum order quantities, returns and documentation. The knowledge gained provides a more accurate Availability requirement in the Supply Chains Design Map.

The Map can then be enhanced with the customer order segmentation policy, based on a Cost to Serve analysis of the supply chain cost drivers by customer. This enables an Available to Promise (ATP) process to set expectations for customers concerning the order arrival date and time. Performance is measured against the actual date and time.

To protect the ATP dates and times, calculated inventory buffers are implemented for each outbound supply chain, based on the Co-efficient of Variance (CoV) calculations and for specific supply items, Vendor Managed Inventory (VMI) can be implemented.

To make the Customer Care approach a part of the corporate culture, there must be an alignment between Supply Chains Operations and Sales teams. To achieve this at the Tactical level, Sales & Operations Planning (S&OP) is the approach for planning Availability of products. At the Operational level, the probability measure for deliveries is Delivery in Full, On time, with Accuracy (DIFOTA), which provides guidance concerning the likelihood of meeting customers’ expectations.

To gain an improved alignment between the Supply Chains group and other disciplines, the following approach is required:

- Establish a common understanding in the organisation concerning the meaning, structure and role of supply chains and the constituent teams. Identify their expected value in improving the customer experience with the organisation

- Identify the desired visibility through the core and extended supply chains for items, money, transaction data and information

- Establish the extent of cross-function alignment (co-operation, co-ordination and collaboration) required between the Supply Chains group and other teams within the organisation

- Use ‘one version of the truth’ for employees, customers and suppliers. Identify the processes for access to and use of common data and information throughout the organisation’s core supply chains

Achieving Customer Care and supply chain financial performance objectives also requires MBWA – management by walking around. It is not sufficient (or healthy) to be staring at a computer screen. Get up from the desk and talk to people as you walk around; when they see that you are genuine in your interest, the suggestions for improvement will flow.