Why change?

Does your company or organisation employ a person responsible for all aspects of supply chains and who reports to the CEO or a senior executive? Surveys indicate that the majority do not. But with all the media coverage of events that disrupt supply chains, why is this?

It could be that the majority of businesses are structured as a collection of departments or functions (based on the division of labour theory), with a number of departments reporting to a manager, which could report to another level of management. A different approach, even for part of the business, will upset this power structure within management and is likely to be resisted.

In the functional structure, each function has a manager with an objective and budget to achieve (and maybe with an achievement bonus attached). This is supposed to ensure the most efficient use of resources, but it encourages a ‘silo’ approach that discourages co-operation and collaboration.

But Supply Chains are cross-functional and flow through operations, not recognising internal corporate boundaries; instead relying on effective processes. These are best managed by cross-functional teams that encourage collaboration.

Flow Process supply chains

A proposal to transform part of an organisation from an inward-focused ‘vertical’ structure to a more outward-focused ‘horizontal’ flow business can be the cause of resistance against change. So, what can be gained from a supply chain organisation based on processes?

Importantly, as companies operate on how they relate to their markets, businesses in the same industry can structure their supply chains organisation in different ways. So there is not a ‘best’ organisation structure for your supply chains – it depends on many factors.

Given that the Aim of an organisation’s supply chains is to ‘satisfy the needs of customers’, then the main objective is ‘Availability of products and services’. Availability can be defined as ‘the time-related positioning of internal and external resources to provide availability of goods and services for customers at the lowest total cost’. This requires managing the flows through supply chains, of items, money, transactions and information.

Managing Flows

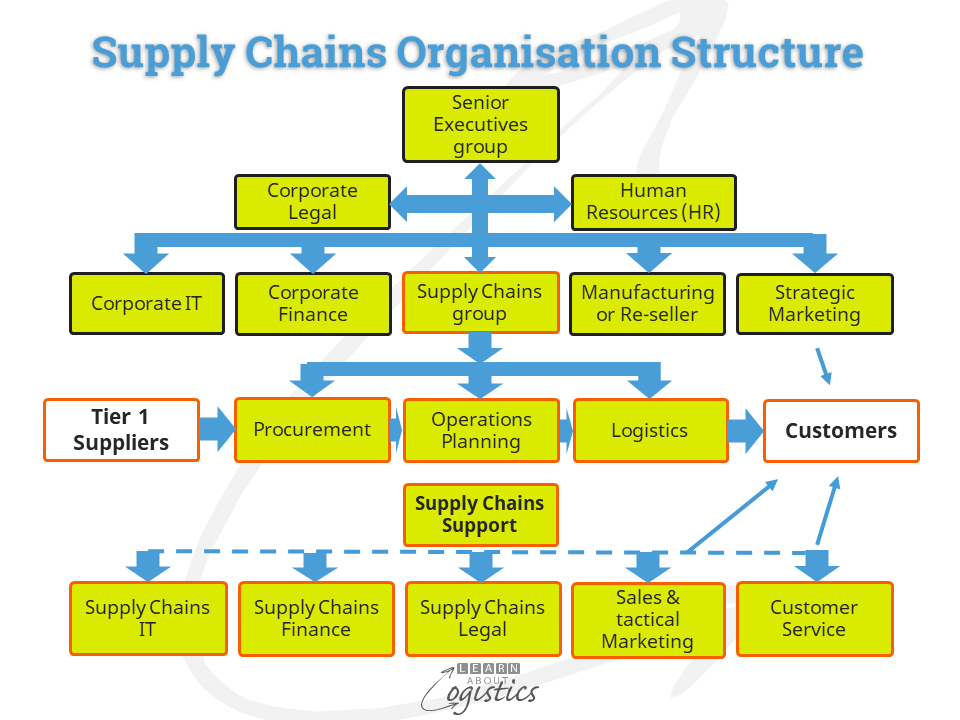

The diagram illustrates that the Supply Chains group is placed at the same level as other senior executives. This recognises the visibility and resources associated with supply chains. And working with the senior management group, the role can influence the business strategy to take advantage of value creation opportunities in the supply chains.

Due to the independence of organisations that comprise the Supply Chains Network of your business, it is unlikely they will become ‘integrated’ within the Network. Even within a business, the degree of integration within the supply chains depends on:

- Homogeneity between business units: how similar are products between the business units

- Geographic spread: the locations of business units (especially internationally)

- Functions located in the Supply Chains group

To manage flows through supply chains, the diagram shows that Procurement, Operations Planning and Logistics should be brought together as the Supply Chains group. The need for Procurement is to build collaboration with critical Tier 1 suppliers and develop relationships to understand the supply markets on which the organisation relies. These are not objectives when Procurement reports through Finance.

The organisation chart also identifies the support functions that could, depending on the size of the business and its culture, be incorporated into the Supply Chains group.

- Supply Chains IT: Supply chains are increasingly IT centric, with at least 70 percent of corporate data linked to supply chains. Applications software; communications integration and interfacing; mobile computing; sensors on equipment for ‘in transit’ visibility (the Industrial Internet of Things (IIoT)), are all part of supply chains.

- Supply Chains finance: Two measures of supply chains performance are working capital and cash flow; also the approval of credit for customers and possible financing arrangements for suppliers.

- Supply Chains legal: When relating to external parties there are legal and governance requirements. Also, to identify and manage compliance with international and domestic laws and regulations.

- Sales and tactical Marketing (e.g. promotions): As Sales can only sell what is available, the function is linked to supply chains

- Customer Service: The information tool used should be ‘Available to Promise’, provided by Operations Planning

If these functions work within the Supply Chains group, the structure can be based a matrix management (dotted line) relationship. This implies that the person responsible for supply chains does not take management responsibility for all an individual’s activities.

Organisation structure for supply chains

The senior supply chain person is responsible for the performance of flows through the supply chains. This provides the potential to optimise the overall result, although not necessarily optimise individual functions.

Responsibility for decisions concerning supply chains is a reflection of the organisation culture, identified by the level of autonomy and influence allowed for business units. That is, the extent to which an enterprise is centralised or decentralised for decisions. Questions to ask are:

- What decisions are critical within the organisation’s Supply Chains Network?

- Where in the supply chains organisation structure are/should these decisions be made?

- Do/will the people expected to make these decisions have sufficient authority?

At one extreme, business can have common strategies, products and organisation at all locations of the business. Should there be a centralised Supply Chains group reporting to the CEO? At the other extreme is to recognise differences between business units. This can result in a decentralised group of separate functions that co-operate and co-ordinate the ‘flow’ of items, or a structure of independent operations with local management empowered to take independent decisions. Or the Federal (Centre-led) organisation structure, which is a hybrid of centralised and decentralised.

At the centre, the Supply Chains group has its focus on strategy planning, strategic sourcing and logistics policy. It also gathers and shares knowledge about the organisation’s supply chains network and improvements. Tactical planning decisions and operational execution is the responsibility of strategic business units (SBU), but the centre consolidates transaction data for analysis of supply chain performance.

This blogpost has discussed some options for consideration as a Supply Chain group is formed. The group and processes to be managed must be designed for your organisation – importing a model from another organisation is unlikely to be successful.