The same view for sales and supply chains.

Your successful enterprise cannot be ‘demand driven’ if it is not ‘supply supported’ – a statement that appears to be obvious. Yet I recently read an article which said the ‘old’ supply chain focus was outdated and the ‘new’ focus will be on the customer and demand management. As if the customer clicks their finger (or keyboard) and everything just happens to satisfy the demand!

This idea was promoted a few years ago under the label of ‘demand driven supply chains’, so now we are getting a rehash, with likely the same indifferent response. If an organisation’s management considers their supply chains are not responsive to customer needs, that is not the fault of supply chain principles and techniques, but a problem for management that is not implementing an integrated approach to serve customers.

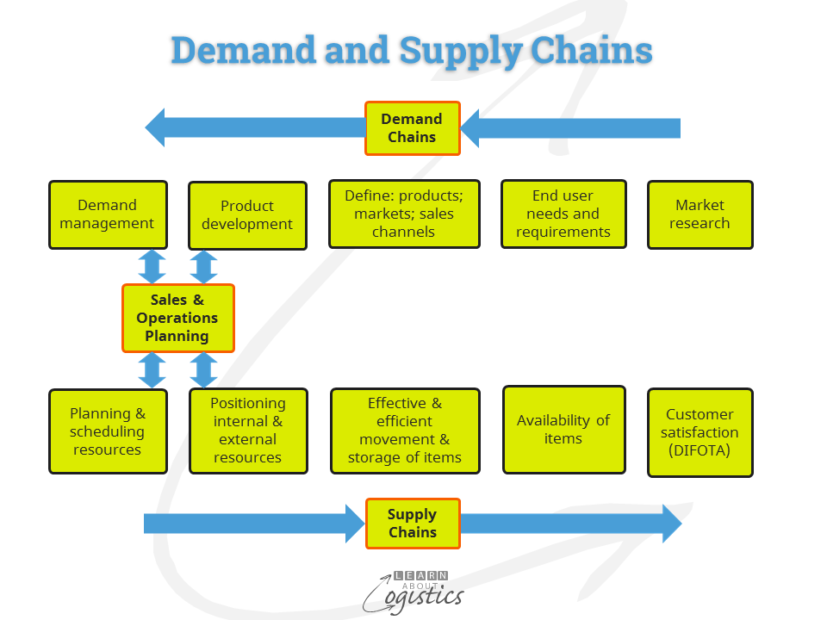

Customers are the focus in all successful organisations – customers pay the bills. But how do you recognise a customer focused and demand driven business among your customers and suppliers? There will be a structured process for balancing ‘demand driven’ with ‘supply supported’. If there is not a structured process, then fine words about customer focus will not overcome the omission. The diagram below illustrates the model; at its core is Sales & Operations Planning (S&OP), a process has been discussed in the business media over many years, but much less acted upon in organisations.

The diagram example relates to organisations that sell, make and distribute consumer products; but the principles and process of demand and supply are applicable in enterprises that import products or contract out their operations. It is also applicable for businesses selling logistics services, such as 3PL, a loading terminal for commodity materials or a shipping container park.

Demand Chains commence with market research to improve understanding of end consumer attributes that drive buying behaviour. Market research leads to a definition of end user needs and technical requirements. This information is input to the products required for different markets and identifying the sales channels that can best penetrate those markets. Products are then developed or upgraded.

The final step in Demand Chains are the three techniques of Demand Management:

- Demand Sensing: helps to identify buying trends for consumer products, through analysing the data generated within each sales channel. In developed countries, retail outlets may provide scanned barcode data captured at the point of sale (POS); however, in developing countries this is less likely due to limited POS data collection in rural areas.

- Demand Shaping: incentive programs designed to increase customer and consumer demand for products. Programs include new product releases, current product upgrades, product promotions, price reductions, commercial buyer (or trade) incentives and sales force incentives. The challenge is that uncoordinated implementation increases uncertainty through the supply chains

- Demand Planning: builds demand or sales forecasts from Demand Sensing and Shaping inputs; the plan establishes the best estimate of market demand and profitability for the products on offer

However, the Demand Plan is is not worth much without a process to align it with the Supply Plan. The lack of a communications channel through which to discuss the Demand Plan means that those involved in planning supply receive the Demand Plan ‘over the wall’. Operations Planners can therefore make modifications (‘improving’ the plan), due to a lack of trust in the capability of sales to provide a plan that is not influenced by ‘stretch’ sales targets.

S&OP is a business process

S&OP is the structure for linking the Demand and Supply Plans. How it works has been discussed in previous blogs. Critically, it is not a monthly budget update or weekly schedule meeting. The S&OP process provides a vehicle for an agreed Supply Plan that positions internal and external resources (items, people, equipment and suppliers), to provide effective movement and storage of items, providing availability for customers (the objective of Logistics). The potential to provide product ‘delivery in full, on time, with accuracy’ (DIFOTA) means that customer satisfaction can be increased.

In S&OP, the term ‘sales’ includes all departments or groups working in the demand side of an enterprise. This includes sales, marketing, product development and demand planning. The term ‘Operations’ includes the functions that work to supply products and services for sale. They include the supply chain group (Procurement, Operations Planning and Logistics), production and technical/engineering.

Other function involved in the S&OP process are:

- The P&L responsible manager (division, country, site etc.), who, as chair of the S&OP management group, ensures a balance between the ‘sales’ and ‘operations’ functions; because, in the early stages of implementation, executives will try to use their power and status to try and gain an advantage

- Finance has a core role to evaluate the proposed plans on the basis of cash flow, financial management and profitability. But, S&OP is a business planning tool, not a finance department budget routine

- HR/Personnel and

- IT

Although functions may have competing priorities, these become secondary to achieving the S&OP output. Therefore, all members of the management team are held equally responsible for the success of S&OP. This reduces ‘finger pointing’, forcing executives to jointly resolve problems and improve the S&OP process.