Changes in supply chains starts with you

Currently, here are many business ‘re’ words being used in commentary about changes required to supply chains. Terms such as: responsive, resilience, re-shore, restructure, regionalisation and redundancy.

Building the Supply Chains Strategic Plan for your organisation’s current and future supply network will need to challenge assumptions about the behaviour of different flows and the risks at nodes and links through the network. A good explanation of the options available for different supply chains has been developed by the consulting firm McKinsey.

But, how many businesses will actually plan to make staged changes to their supply chains and how many will just carry on as before and react to changes when a future situation becomes too difficult?

Before commencing the project to build a knowledge bank, the executive and managers in supply chains disciplines should question their willingness to change. Too often, change is what we expect others to do; words such as adaptable, flexible and versatile are increasingly expected of employees, but less so for managers and senior executives, because they control the narrative.

Humans like predictability, because it enables them to organise their lives without having to deeply consider possible disruptions. Likewise in the work environment, predictability is favoured, because it allows for order in the work processes. Uncertainty, with its underlying risks, is not favoured due to the dangers of not knowing and therefore having to provide excuses for ‘failing’ in a response.

However, the complexity of supply chains means that disruptions should be expected, but at unknown times. Therefore, leadership will increasingly require a willingness to both accept disruptions and change and to demonstrate that change provides value for the business. Success in this approach requires managers and executives to have confidence in the knowledge bank’s information about their organisation’s supply chains and supply markets.

The Knowledge Bank

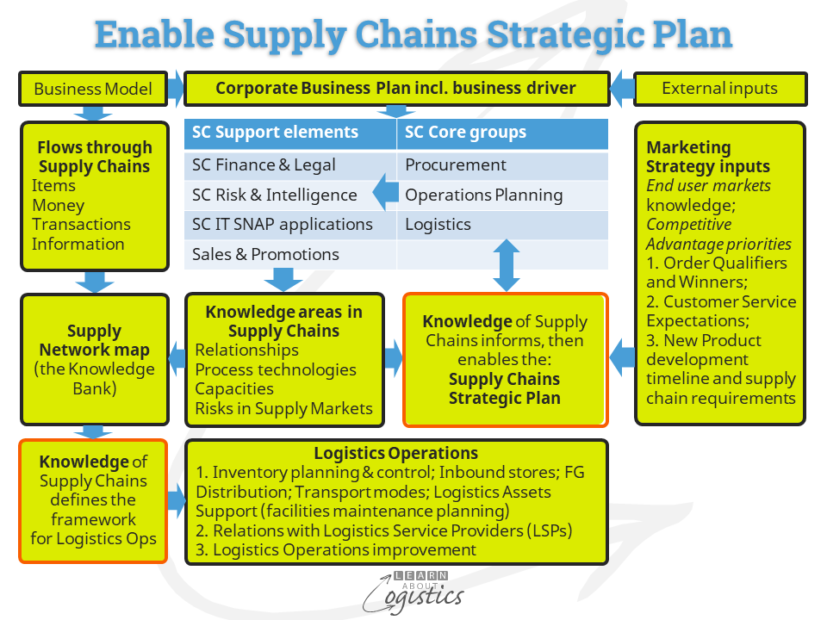

The diagram below illustrates the flows of data and information that is structured in your organisation’s Knowledge Bank, more commonly known as the Supply Network Map. Knowledge defines the framework for Logistics Operations and informs, then enables, the Supply Chains Strategic Plan. This is developed from amalgamating inputs provided by the three strategic plans from Procurement, Operations Planning and Logistics.

A Supply Network Map (the network contains all the supply chains of a business) is structured to commence with products sold by the business. Then identify all materials (semi-finished, components or ingredients) used in the products and their suppliers, upstream from tier 1. Suppliers become more difficult to identify further upstream; instead supplement the supplier data with data and information about the supply industry sector and/or supply market. The Map can be completed with details of tier 1 customers and their customers.

Marketing and the three supply chain disciplines need to be aligned for the 1-3 year horizon of the Supply Chains Strategic Plan. This is to ensure an effective response to evolving market trends – changing phases through the life cycle of products, changes to customer order ‘qualifiers and winners’ and new product timelines and supply chain requirements. The alignment work is done through an extension to the Sales and Operations Plan (S&OP) process, discussed in previous blogposts.

In economic terms, the value that end users gain from a product is called utility. The reason for supply chains existing is to enable Availability of products for the end user, which is driven by two utilities – time and place.

Time utility includes the process time from receiving to delivering a customer order plus minimising the time for all steps upstream in a supply chain to reduce inventory and the total cost of ownership (TCO).

Place utility is about making products physically available to serve current and potential customers, so is concerned with the location of facilities – warehouses and factories. Customer service is also a place utility, in relation to an available, easy to use and informative website, the provision of technical assistance and an after sales replacement parts service.

However, the effectiveness of time and place utility can be influenced by factors that must be identified in the Supply Network Map:

- The stage in a supply chain where a business is located – a primary industry, a producer, converter, fabricator, assembler or retailer (or other sales outlet)

- The ease of handling, storage and transport of the inbound materials and finished products

- The ‘must have’ qualifiers required by customers prior to the sales process

Risks identified in the Supply Network Map

The supply network for a business contains inter-connections between countries, industries and companies that can affect supply (and demand) on a random basis, without advanced warning for the affected businesses. This situation is the generation of unknown and emergent results from within a complex adaptive system (CAS), which is the design concept for a supply network.

To mitigate the effects of emergent results, requires risks to be identified at each level through the Supply Network Map. As discussed in a previous blogpost, the risks that can affect supply chains are: External risks; Supply Network risks; Internal enterprise risks and Internal supply chain risks.

Identifying the criticality of a risk requires a matrix identifying the Likelihood of the event occurring against the Consequences if it happened. To further improve the consideration of risks, consultancies have added some additional matrix:

- Boston Consulting Group (BCG): ‘impetus to change’ – pressures such as financial, commercial, economic or political, against ‘ease of adjustment’, such as the difficulty of replacing certain suppliers and the capital costs associated with moving to new locations

- David Simchi-Levi at MIT: Time to Recover (TTR) to full functionality after a disruption; for a supplier, distribution centre or transport hub, against the Time to Survive (TTS) for the buyer – the time before the disruption influences operations at the buyer. This is a ‘stress test’ that reduces the perceived importance of location for an enterprise and its suppliers

- McKinsey & Co.: The lead time available to predict a disruption against the level of Consequences if the disruption occurs

In times of Uncertainty, risks of disruption in your supply network are likely to increase. Building the Supply Network Map to be the knowledge bank concerning supply chains is no longer an option as the input to the Supply Chains Strategic Plan.