Role of Inventory

The role of Logistics is to provide Availability of items for end users. This requires the management of inventory to be a critical capability for a Logistician. A known factor is the cost of holding inventory, although often under-stated by companies. Less appreciated is the value of inventory to the business.

Experiences of stockouts through the pandemic has re-enforced the main role of inventory – to provide a buffer of units for an item between its demand and supply. This is because the variability of demand for a product is unlikely to match the variability of supply for the finished item or inputs of intermediate items for production. Variability in demand and supply through the supply chains of a business requires calculated buffers, held at various locations in the core and (maybe) extended supply chains, based on:

- inventory form – raw and packaging materials, intermediate (semi-finished) items, finished goods and

- function – cycle stock, safety stock, in-transit inventory, pre-build inventory to support market launches, slow and obsolete (SLOB) inventory required by Sales and Vendor Managed Inventory (VMI))

The value of inventory to a business is recognised within two groups. The first group is used to improve the chance of meeting the expectation of customers for delivery ‘in-full and on-time’:

- Cycle inventory. Inventory that is held at the mid-point through the replenishment cycle (half the order quantity).

- Fluctuation inventory. Inventory held in excess of the cycle inventory to address Uncertainty associated with unplanned events. This inventory is called either safety stock, reserve stock or buffer stock. The calculation is affected by the variance in demand, supply and lead times.

The second group is associated with achieving business strategy objectives:

- Anticipation inventory. Increased inventory held in advance of a peak demand. This can be a product launch, seasonal demand, public and religious holidays, planned shutting for maintenance, extended holiday periods or supplies of a item becoming restricted

- Hedging inventory. Buy and hold additional commodities e.g. natural fibres, grains and metals, when the global price is considered to be low. The preferred option is to secure the future price of the material through trading contracts for future purchases on an international commodity exchange

- In-transit or transport inventory. The buyer purchases and arranges transport for the items. The inventory value becomes part of the buying company’s assets and is designated as in-transit inventory. Operationally, the inventory is incorporated as a ‘floating warehouse’, with a calculated availability date.

Inventory and Management

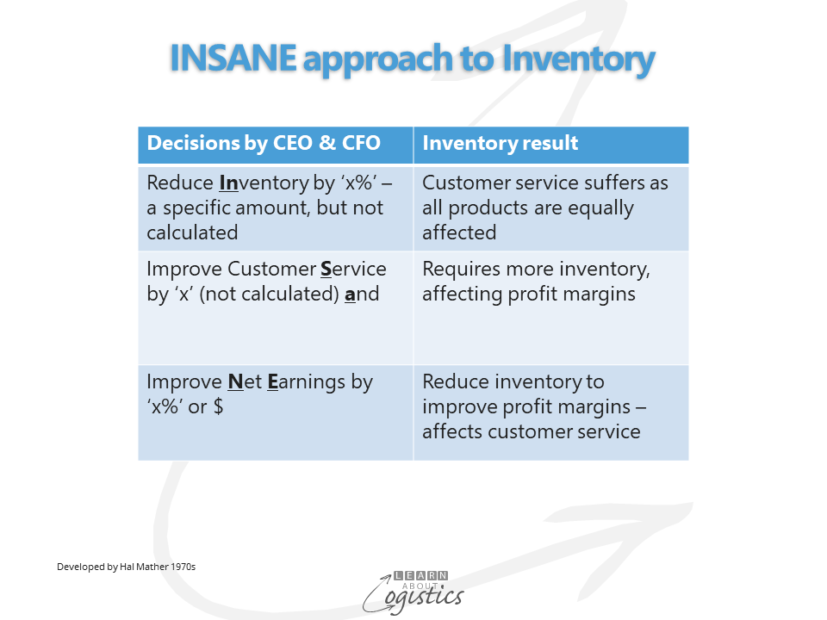

While the responsibility for managing inventory resides within Logistics, there is a responsibility by senior management and marketing/sales not to make decisions that adversely affect the ability of inventory to provide Availability for customers.

A recent article concerning current shortages of some products in America stated that a particular company “now held 180 days of sales in inventory”. The exact 180 days figure (not 179 or another number) is a giveaway – it was an edict from the CEO. This is an example of the INSANE approach to inventory by senior management, with unplanned consequences.

Senior management are likely to view inventory as a financial item (inventory is an asset in the Balance Sheet), with a financial rather than physical objective. This is a challenge for Logisticians when establishing the Inventory Policy. To overcome the bias, the total inventory required to support the business model and the consequential commitments on suppliers must be calculated and presented. If the financial budget cannot support the required physical inventory, the business model will need to be reviewed.

Inventory and Marketing/Sales

Marketing/Sales can also make or influence decisions that have a detrimental effect on the management of inventory. You may have experienced some (or all) these decisions:

Sales targets, whether annual, quarter or monthly. The sales director (or similar) convinces all that a substantial increase in sales of a product group is possible. The new target requires a pre-build of inventory at additional cost and effort. When the inflated sales do not happen, Logistics is usually blamed for the targets being missed – sufficient inventory was not available or was in the wrong location – even if it was an isolated situation.

Sales targets, with a period end results in the ‘end of month rush’ to meet targets (and gain the bonus). This requires a build of inventory and ‘rushed’ output from factories or suppliers. From a customer service viewpoint, the first day of a new month is no different from the 30th day of the previous month; the requirement of customers is to receive delivery of the order ‘in full and on time’.

Sales promotions: Price promotions (or other offers) require an inventory build and often, additional delivery charges; costs which are usually not charged to the promotion. This makes the initiative appear more profitable than the actual situation.

National promotions, due to their size, are known and planned, but promotions for a product line in a state or province can happen without a trigger to increase inventory. That is until the state sales manager contacts the DC to ask where the additional inventory is located.

Another promotion type is to deliver a ‘buy 12 get one free’ offer when the standard distribution multiple is (say) 12. This has additional inventory handling costs, again usually not charged to the promotion.

Advertising decisions that provide a created seasonality. If advertising a product prior to a normal peak in consumer demand, such as Christmas and Chinese New Year, the peak will become higher. If the item is imported or has imported components, they must be ordered earlier to account for extended supplier lead times and shipping capacity challenges.

A type of seasonality can occur with erratic advertising. If a product promotion runs for a defined period, sufficient inventory must be available when consumer demand increases when the advertising occurs. But inventory must be planned to decrease at the end of the promotion or when a competitor promotes their offer.

Payment terms and payment time discounts influence inventory. Some companies require payment for orders against Statements that are sent to customers on pre-defined dates. Customers will place their orders to take advantage of the payment time and any discount for early payment against the Statement. This requires increased inventory to satisfy the ‘bunching’ of customer orders around the payment time dates.

For Logisticians, managing inventory is more than reducing volume and costs. It is understanding how inventory affects and is affected by management decisions and business interactions with customers and suppliers and importantly, the analysis required to establish the ‘right’ levels of inventory.