Digital supply chains into the future.

Technology trends are often driven by businesses which have a lot to gain from building a ‘buzz’ around their products or technologies. We currently have a steady stream of articles and commentary about ‘self driving’ cars that make it seem an inevitable occurrence.

At a recent IT exhibition, I was pleased not to be sold ‘smoke and mirrors’ by sales staff’. Of the approximately 120 stands, only three were selling a software product. Excluding those selling IT security, the remainder promoted their ability to develop applications (preferably marketing and sales directed), using particular tool sets. This requires knowledgeable users to construct a requirements document, for conversion to a systems specification. More about this later in the blog.

Thankfully, the sales staff did not use the term ‘digital supply chains’ to describe the IT based future. The term digital supply chains contains words such as connected, intelligent, scaleable and fast. It also assumes that the management focus in supply chains will change from minimising costs to effective collaboration within an organisation and with external parties (suppliers and customers); something we have been waiting for decades to happen.

Articles state that to achieve digital supply chains requires integrated supply chains that are fundamentally digital; just adding digital technology to existing processes is not sufficient. To achieve digital supply chains requires your supply chains to be restructured as a digital supply network that incorporates the flows of physical (material, resources, people) finance, transactions and information.

While this is a laudable objective, the commentators have not recognised the necessary factor that a Supply Network has its own dynamics, by which the nodes of the network adapt and respond to actions of other nodes – all without a ‘network controller’ managing, controlling or optimising the events.

Supply Networks are Complex Adaptable Systems

By having their own dynamics, Supply Networks are Complex Adaptable Systems (CAS). The essential features of a Supply Network are:

- It is non-linear in operation – many ‘ifs’ and ‘thens’ as in a Decision Tree diagram

- Uncertainty in a market grows with increasing flows of resources, money and information. One outcome of Uncertainty is to increase lead times for items – Just in Case (JIC)

- Outcomes are affected by Constraints and Variability. Their properties interact dependently, independently and inter-dependently within a Network

- These influences through the Network provide results that will be Emergent and also Cumulative

- Supply chain processes require Reliability in planning. Instability will result with too much responsiveness required in the system

Given that Supply Networks are CAS, a fundamental question in the design of digital supply network systems is “how necessary is a tight integration of planning and operational modules required, when the organisation must be reactive to Emergent events?” The requirement is that not all modules need to be tightly integrated and planning modules must not operate in a real time mode.

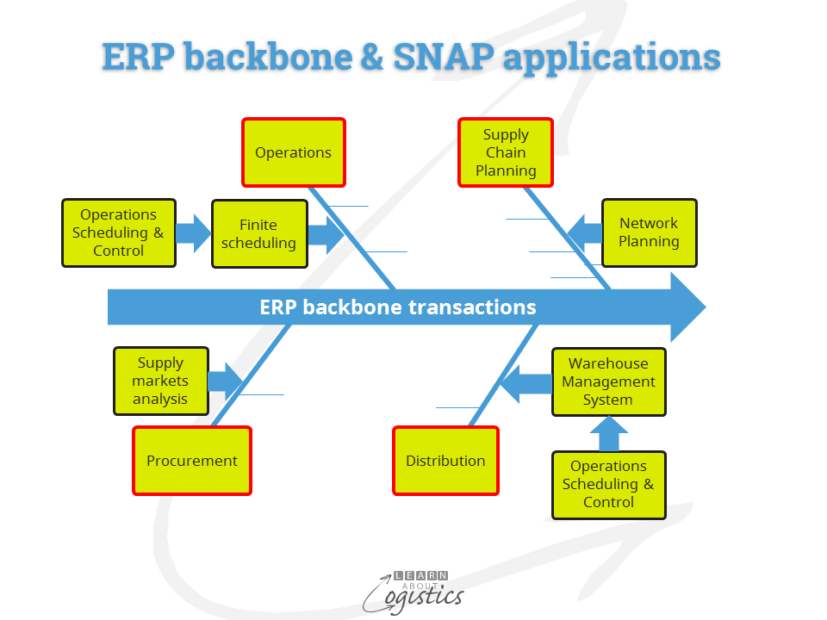

This approach lends itself to the system construct of a simpler Enterprise Resources Planning (ERP) transaction backbone for your organisation. It would contain an audit trail of sales orders, purchase orders and payments, plus basic accounting, operations control and HR data. The ERP backbone would be supported by Supply Network Analysis and Planning (SNAP) applications that access the base data from the backbone, complete their tasks and send the solution back to the ERP backbone for action and consolidation.

When thinking about IT requirements, commence with the customer and the market; then work back through the demand network, your organisation, then the supply network. Design solutions which address your real business problems concerning supply chain effectiveness, including:

- building more agile demand and supply networks that apply in your markets

- use of market and distribution channel data

- use of streaming data

- accessing data from sensors

- using analytics to make sense of large data sets

- achieving time to market for new products and delivery in full, on time, with accuracy (DIFOTA) for established items

Decisions concerning the SNAP applications required in your organisation will depend on the contents of the Supply Network strategy document. This is an amalgam of the strategy documents for Procurement, Operations Planning and Logistics. The strategy is a translation of the item/volume data into:

- customer and supplier segmentation

- standardisation vs specialisation situations

- cost to serve

- inventory strategies concerning form and function. This includes:decisions concerning safety stock buffers, push-pull demand decoupling points and postponement

- total cost of ownership (including sustainability)

- hiring and retaining skilled people

- Sales and Operations Planning (S&OP) as the collaboration process within your organisation

- Supply Chain risks, including dependency on IT networks and the potential vulnerability of networks to security breaches or hacking attacks

All this seems to be a big task and it is; especially in mid-size organisations. But the good news is that while the pundits are forecasting a complete change in supply chains and business processes in the next few years, evidence of past IT hype shows that the majority of organisations will be implementing ‘new’ software applications over the next 15 – 20 years! Do not be rushed into decisions.concerning the design, selection, approval and implementation of supply chain applications that must be ‘fit for purpose’ in the digital environment.