Recovery will take time

Black Rock, the world’s largest fund manager has stated that the crisis will fundamentally reshape business practices, society and consumer habits – rethinking the way people work, shop, travel and gather. There will be a ‘new normal’ way of functioning and businesses will need to adapt.

And the timeline for recovery could be long. The investment bank, Morgan Stanley warns in a recent newsletter of no quick return to ‘business as usual’ in the US: “…we see 2Q20 GDP contracting as much as 45%, followed by a soft 3Q and a rebound in activity in 4Q20 and into 2021…even with the expected rebound, the level of output (in the US) at the end of 2021 in our bear case remains 11.5% below its pre-recession peak”.

The political and financial decisions made by governments during and following the crisis could influence economies for at least 10 years.

Responsible fiscal management will require questions to be asked about how governments will raise taxes from businesses and individuals, including resources and land taxes, profit shifting by multi-national companies and wealth taxes.

And how are taxes to be spent for education and health, state pensions and security? Sectors in an economy that are badly affected, such as aviation, tourism, hospitality and the arts will require significant financial support from the government.

Decisions and actions about national income and expenditure will affect future economic and structural decisions by businesses and consumers.

The Recovery Phase

Current health restrictions in countries are likely to last at least 6 months. If a vaccine takes 18 months to release, international travel restrictions will most likely last until the end of 2021, which affects travel agents, airlines and hotels.

For planning purposes, it would appear that economic and business recovery could take until the end of 2021. In this period, businesses and consumers will build on their experiences concerning a different way of functioning, so a return to the ‘old ways’ is less likely.

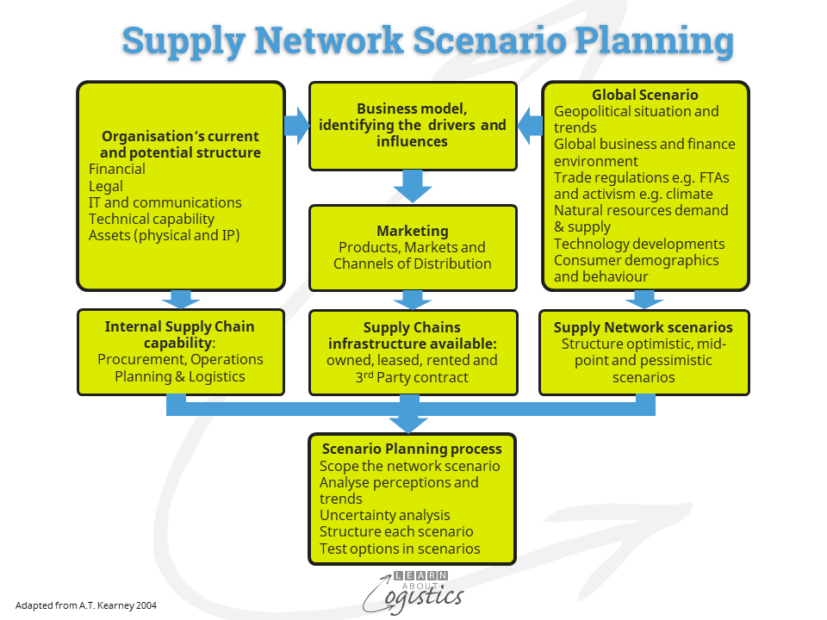

For your business, this will require a re-evaluation of the Business Model to address whatever is the ‘new normal’. The diagram provides an outline of the Scenario Planning process for your supply network.

To establish a revised Business Model, across the top of the diagram are elements to be identified and considered at the director and senior management level. Under ‘Global Scenario’ will be the facts, assumptions and opinions within various headings, of which some examples are listed.

Importantly, given the experiences and lessons learnt from the current crisis, will be a re-evaluation in many developed countries about the meaning of globalisation and possible responses:

- Reduce the level of reliance on any one country for materials, components and finished goods

- Requirement for production and storage capacity to be located in a country for ‘critical’ materials and items. Examples could be steel, filament for surgical masks, medical equipment and pharmaceuticals

- Encourage (through industry protection) new companies to establish and stay within a country

- Imports are reduced by countries through: imposition of trade restrictions; changes to trade agreements and changes in consumer preferences

Other potential changes which could occur are:

- Decline in the amount of physical retail space required in developed countries

- Increased use of on-line ordering for grocery and other consumer items. Challenges of increasing ‘last mile’ deliveries may lead to government imposed delivery solutions

- Working from home arrangements for staff, including teleconferencing. Less office space required; less travel and hotel reservations

Each business should plan its own future, because it is unlikely that entire industries will be affected uniformly. With the revised Business Model established, the Supply Chain group can consider scenarios for a modified supply network.

Supply Chain scenario considerations

Procurement

As business has been affected in all countries, assess the viability, capacity and availability (lead times) of suppliers, together with any likelihood of shipment and transport delays.

Re-evaluate reliance on sole suppliers or single countries. The review to consider whether:

- Multiple suppliers are required for critical items and

- Critical items to be produced at multiple sites within a region or country

Contract manufacturing performed in low cost countries (LCC) – undertake a total cost of ownership (TCO) analysis, including Just in Time (JIT) inventory policies. Garment manufacture could remain in LCCs.

Evaluate establishing company or contract manufacturing in the country or region where the products are sold (on-shoring and near-shoring). Justified on the use of new technologies under the Industry 4 heading e.g. 3D printing, robotics etc.

Logistics

Outsourced distribution management – undertake a total cost analysis.

Evaluate the aim of major 3PLs to become the information hub for their client’s inbound and outbound movement and storage of items. This presents a risk of being ‘locked-in’ to a 3PL.

Possible increase in freight rates and potential changes to the structure of freight movements:

- Air transport commentators consider there will be 20 to 30 airline groups operating globally and the big airlines that survive will be smaller than at present, with reduced route structures

- Container shipping route rationalisation may increase, calling at fewer ports. This would require trans-shipment or inter-port land transport for landed containers

Potential to co-ordinate operational activities with non-competing businesses e.g. share resources, such as consolidate air freight shipments on charter freight aircraft.

Evaluate whether the business is too enthused with the idea of ‘fast delivery’. Do customers and consumers really want speed, or do they want certainty – delivery in full, on time, with accuracy (DIFOTA)?

Evaluate climate change risks to physical assets from extreme weather events and changing climate patterns.

Scenario planning your supply network

Scenario Planning was discussed in an earlier blogpost. As scenarios are developed, ask questions concerning the impact on:

- material and intermediate items – availability and cost

- logistics services provided to the organisation

- movement and storage of items through (identified) supply chains

- corporate and Logistics Services Providers (LSPs) infrastructure needs and locations

- technology selection and implementation

- knowledge sharing with external parties

- customer and: consumer value perceptions concerning the products and services

- supply chain organisation structure – domestic, regional and international

To analyse and debate scenarios requires the base data to be a reasonably accurate depiction of your organisation’s supply network – the Supply Network Map. It should include the expected Time to Recover (TTR) if critical supplier nodes or transport links become unavailable.

After considering the range of scenarios, a scoping document can be developed. This will identify alternative: suppliers, routing through transport points, storage locations and supply chain organisation structure. It will also provide indicative times and resources required for implementation. The next step is selling the plan to senior management.