Supply Chain thinking.

Understanding how your supply network functions is critical for professionals engaged with their supply chains. Understanding enables the scope and responsibilities of professionals to be defined and importantly, allows management at senior and middle levels in disciplines affected by supply chain decisions to understand why.

How supply networks function became a core interest of mine in the early 1990s. That time has been remembered in this past week, when I read two advertisements for management conferences in which the acronym VUCA was used. In the early 1990s, I read about this approach to strategic thinking, but it went off the media radar and seemed to be forgotten, until now. My interest in VUCA was that it considered strategic thinking based on four conditions:

- Volatility: situations are unexpected, the pattern of events is unstable and the duration is unknown

- Uncertainty: the potential for surprise concerning events, giving a lack of predictability concerning an event’s cause and effect

- Complexity: situations have many inter-connected parts and variables, with unclear cause and effect issues. This can provide an overwhelming totality of data and information available for decision making

- Ambiguity: Cause and effect misunderstandings, including the potential for responding to ‘unknown (but should have been known) unknowns’ and ‘unknown (could not have known about) events.

While VUCA was used in developing corporate strategy, I (and others) considered that the approach had value when thinking about supply chains and networks. The initial challenge was that the term ‘supply chain management’ was becoming popular and typically misunderstood. This was because the term ‘management’ generated ideas that supply chains could be planned, controlled and managed.

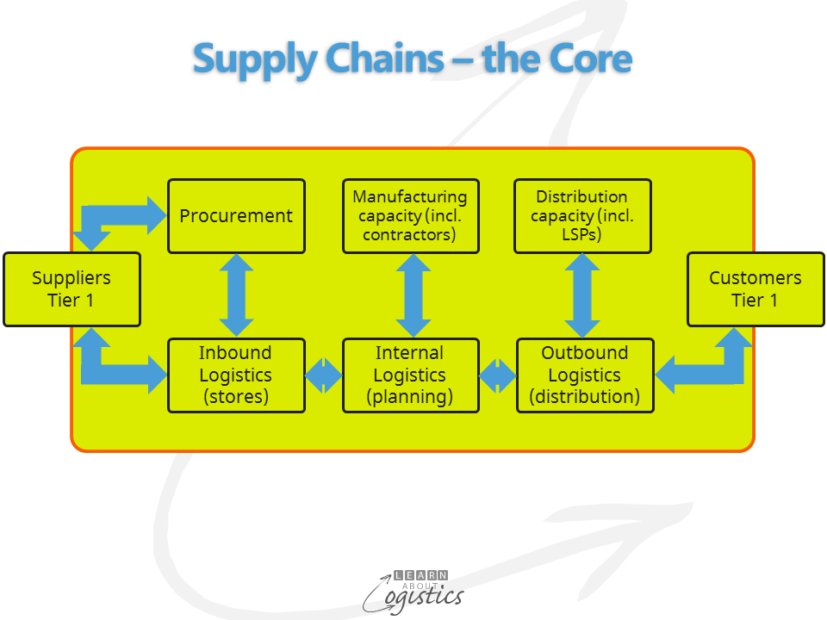

However, management is essentially about the exercise of power in relationships and the allocation of available resources. In each supply chain, your organisation has the potential to exercise management between itself and Tier 1 customers and Tier 1 suppliers through the influence of Procurement, Operations Planning and Logistics – the core function within a supply chain management group. Outside of Tier 1, the capability to influence organisations and events is limited. Therefore an organisation has two levels of supply chains – the Core (which may be ‘managed’ – see diagram below) and the Extended (which is unlikely to be managed); together they are your Supply Network.

Understanding your supply network

Although you cannot manage the extended supply chains, there is a need to understand and map them. Within each chain (and therefore the network) are nodes of operations and inventory, variables that affect the value and availability of inventory and transport links. Between the nodes and links are flows of items, money and information, that does not have a centre of control. However, a supply network adapts to changes, interruptions and disasters, making it a Complex, Adaptable System (CAS), which cannot be managed, but can be understood.

The essential features of a Supply Network as a CAS are:

- Uncertainty that grows with increasing flows of resources, money and information. Uncertainty is also increased when the current situation in a supply chain may change, but when and to what extent is not known. It is then amplified by the level of acceptance in the organisation concerning:

- Distances from suppliers and customers

- Focus in operations on speed and efficiency rather than effectiveness

- Low safety margins concerning time, inventory and working capital

- Non-linear in operation – many ‘ifs’ and ‘thens’ as in a Decision Tree diagram

- Complexity, Variability and Constraints, which interact dependently, independently and inter-dependently, affecting outcomes

- Emergent and Cumulative results are the outcomes, over which management has little control

If too much responsiveness is required of the supply network, the result can be Instability, unless structural and process changes are made. Effective planning of core supply chain processes requires Reliability and Consistency, but to achieve this state in volatile supply chain situations requires parts of an organisation to be connected and working together – Co-operation and Co-ordination, leading to Collaboration. Only after this is achieved within an organisation can influence be exerted on the core supply chains to do the same.

All these pressures and influences on your supply chains can be summarised as risks. Therefore management of risks is a core capability of a supply chain management group. The essential question asked as the network map is constructed is “What is the likelihood of X happening and if it does happen, what are the possible consequences?”.

Examples of risk management situations in supply chains occurred this week. First was the writedown in the value of Toll Holdings, Australia’s largest 3PL. The company was purchased in 2015 by Japan Post for $A6.5 billion, a 49 percent premium to the share price. The business has now been written down by $A4.7 billion. There are various reasons for this situation, but there are potential risks to be evaluated by customers and suppliers. In this same vein, Germany’s Deutsche Post purchased UK Mail for a 43 percent premium, so are there risks with postal organisations getting bigger to compete in eCommerce transport and distribution?

The second example is a new (and readable) research report entitled Rethinking Transportation 2020 – 2030 (but written for an American audience). The premise is that developments in vehicle technologies will follow the ‘S curve’ of technologies such as personal computers and mobile phones. This means that major changes in the transport systems of America (and potentially other countries) will occur earlier than many think. Whether you agree or disagree with the views expressed, they provide the basis for a risk analysis of your supply network.