Adapting to change

Commentators are talking about mid to late 2022 for a return to a relatively balanced demand and supply situation in global supply chains, But that will not be the end of the matter; there will be more frequent (and likely severe) disruptions to supply chains in the future.

This is not the first time that supply chains have been stressed. In the past, supply chain challenges were solely caused by direct human actions and the responses by people eventually resolved the demand and supply situation. However, the challenges of 2021 contain an additional factor – climate change.

Like a Supply Chain Network, natural systems, such as the atmosphere, oceans and living beings are complex. A feature of all complex systems is that they seek equilibrium between the forces affecting them. However, when an external force pushes a system too far from its equilibrium, the system will suddenly change its structure and establish a new equilibrium. Once such a change has happened, it is near impossible to change the system to what it was.

Increased volatility in a system provides warning signs that a major change may occur; but the timing of a change to a system is difficult to predict. As volatility in natural systems increase, your organisation’s Supply Chains Network will adapt, but without your guidance or control.

Consequences of change

Since the 1970s, brand companies have reduced their involvement in manufacturing because they wanted to make the (mainly) fixed factory costs a variable cost. As a result, they have become more dependent on third party distribution (3PL) business facilitating extended supply chains supplied by contract manufacturers and suppliers, often located in low cost countries.

The flexibility of having global suppliers allowed brands to deepen and extend their product ranges, resulting in shorter product life-cycles and higher turnover of products and increase in stock keeping units (SKUs). The outcome was wider fluctuations of demand, caused by users changing preferences depending on promotions. This generated optimistic (and less reliable) sales forecasts, which made contract factories more difficult to predict and plan.

These changes to the business structure did not modify the business objectives of senior management. For example, the objective behind JIT (and later ‘Lean’) is the elimination of waste – the reduction in inventory is an outcome; but most businesses only considered reductions in inventory, not the elimination of waste.

The current supply chain disruptions illustrate that changes to supply chains are the result of executive financial decisions and a ‘cost down’ approach, implemented without improvements in planning knowledge and organisation structures.

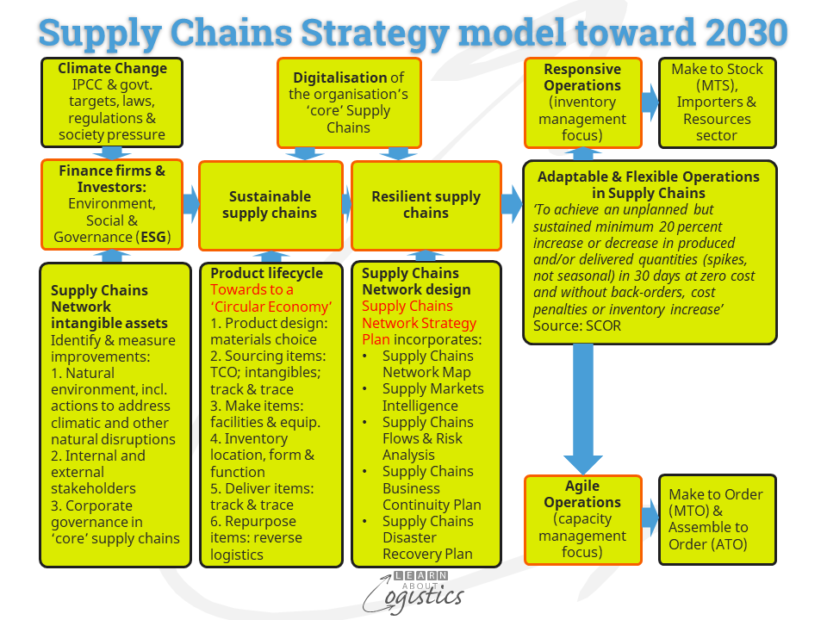

Managing the response

The diagram below is a LAL template to illustrate the type of thinking required by supply chain professionals in the new environment of ongoing disruptions caused by volatility in natural systems – disease pandemics, tropical storms (cyclones, hurricanes and typhoons), floods, droughts and fires, plus earthquakes and volcanoes. As found in the current pandemic, volatility in natural systems can influence some unexpected buying decisions by consumers.

How to respond to disruptions will become an integral part of supply chains. The choice appears to be: a capability for ‘instant’ response; that is, sell one – make one; integrate (re-shore and nearshore) manufacturing as a core function of a business; an investment in redundancy of inventory or capacity, or a change in the way that supply chains are planned.

Sell one – make one will mainly exist in locations close to consumers. Current examples are establishments making and selling street food; bread; confectionery; petite-fours (cup cakes/tarts) and ice cream. The development of smaller scale automation and additive (3D) manufacturing will enable other items to be locally produced and sold, such as knitted clothing and service parts.

To re-shore or nearshore manufacturing from low cost countries is unlikely on a large scale. The needed change to processes, and the development of new suppliers would increase costs without guaranteeing an improvement in adaptability and flexibility and therefore responsiveness. The same argument would apply to increasing inventory or capacity.

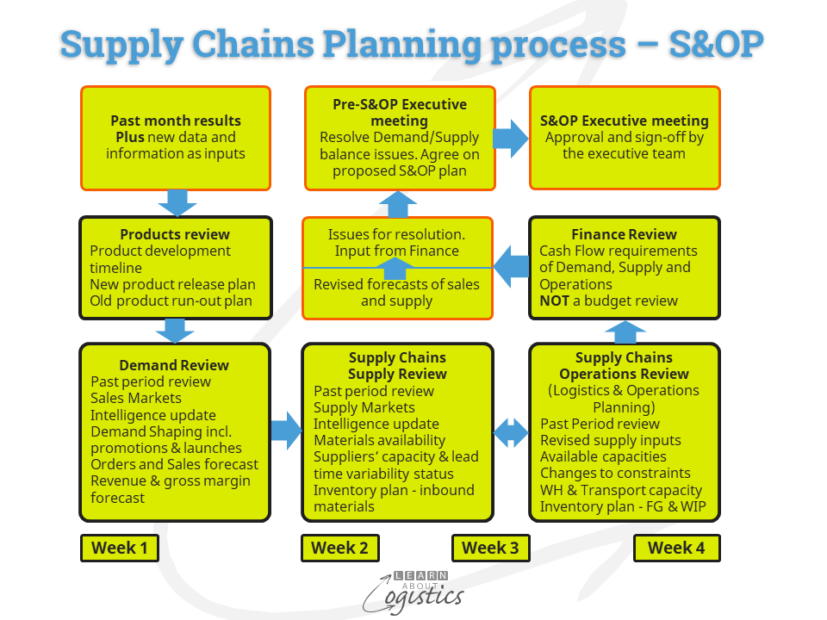

The option with most appeal is to improve the way that changes in customer/consumer demand and global supply are recognised and planned. The approach has been around for about 40 years, but not widely adopted. It is Sales & Operations Management (S&OP), a process to balance demand and supply. As shown in the diagram below, the current S&OP follows a four week review and action process, but in the new environment, this is likely to be considered as too slow for a response.

To address the new situation of enhanced volatility in supply chains, a computer based ‘Response Management’ systems is required at the product family level and based on the S&OP model in the diagram, which operates in a ‘real-time’ environment – in-house or via the ‘cloud’.

It will be a ‘what-if’ modelling technique that accesses multiple application data bases to evaluate available resources and identify alternatives against current and expected changes in product demand or supply availability. It must have the ability to rapidly identify possible actions over the planning horizon, given the resources (materials/FG inventory, production capacity in-house and at suppliers, logistics capacities and cost parameters) actually available and to test and rank the options. Some attributes of the application should include:

- Pool region finished goods inventories but take account of customer order and contract related commitments

- Analysis that provides visibility of supply and production constraints across the supply chains

- Identify substitutions where material/component shortages exist

- Plan product introductions and end-of-life runout, using what-if alternatives of technical/engineering changes and sales promotions

- Identify timing of new supplier introduction by modelling supplier inventory data and production plans

- Simulate the impact of pending and released technical/engineering changes

- Track changes in demand and lead times through the supply chains

- Enable demand/capacity balance by simulating options based on available capacity data

While there are applications that support the current S&OP process, LAL is not aware of an application that meets the needs of Response Management, but it will not be long before an application is available.