The elements of S&OP.

For Sales & Operations Planning (S&OP) to be successful within your organisation, three elements must work together: People, Process and Applications. As discussed in my previous blog the most critical element is people, S&OP is a journey towards collaboration so, without the willingness by senior managers (and their reports) to change behaviour a S&OP implementation will fail.

The second element of S&OP is process. The initial requirement is that all strategic business units (SBU) and divisions have a common approach, to ensure the numbers produced will mean the same throughout the organisation. This will address:

- Business Strategy: The common driver for all S&OP in an organisation

- Supply Network definitions: A common definition is required for demand, supply and planning elements

- Executive team: The role and responsibilities must reflect the power structure within an organisation e.g. global planning authority; region responsibility; matrix organisations (local operations and region/global services)

- Planning cycle: A standard frequency. To facilitate comparisons, a client organisation adopted a common four week planning period, with 13 planning periods in a year

- Reporting structure: Each S&OP process is chaired by its P&L responsible manager

- Supply Network flows: Mapping the nodes and links of the Network. Illustrate the inter-relationships of SBUs/divisions within the enterprise

- Time Horizons: The S&OP planning horizon is typically in the range of 12 – 24 months, but this can differ depending on specific circumstances (one of my clients had a planning horizon of 3 – 6 months). The minimum time will be at least the longest lead time item in the Bill of Materials (BOM)

Because the the supply chain group (Procurement, Operations Planning and Logistics) has responsibilities across the organisation and is the major beneficiary of S&OP, they should have the responsibility of guiding the process. Specifically, the Master (senior) Planner of an SBU should be responsible for facilitating and reconciling the completion of each step in the process.

SBU managers, responsible for P&L, will write their S&OP policy document. This includes: an overview of the process and its objectives; identifies the participants in the process (see diagram in the previous blog) and their responsibilities; the expected outcomes from each step through the planning cycle and the S&OP meeting dates and times over the next 12 months. The document must clearly state that S&OP is not:

- The business plan: S&OP provides a structure for planning to address medium-term situations

- A budget review: S&OP is based on current inputs concerning demand and supply; therefore S&OP is an input to budget updates, but should not be constrained by budgets

- A weekly and monthly operations meeting: S&OP is a process focused on the whole organisation

The S&OP process

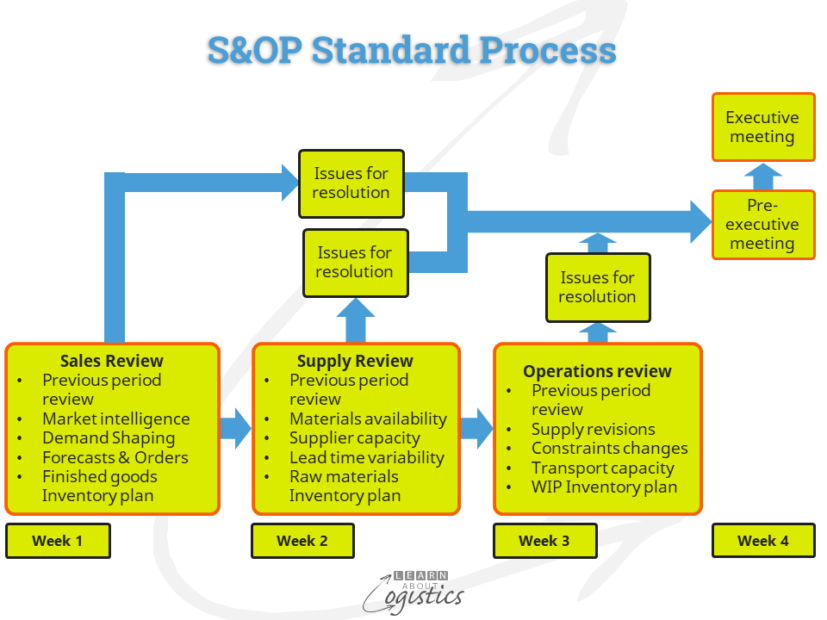

The process consists of focused review meetings for each discipline and an Executive meeting for decisions. The diagram shows a standard model, but the actual number of review meetings are decided within each organisation. For example:

- Finance input is part of the pre-executive meeting

- Additional meetings are inserted for product review and finance review

- For enterprises without manufacturing, the operations review is modified or deleted

The reviews in the diagram provide the main topics for discussion and identification of challenges.

A feature of each meeting is not to last longer than one hour (some organisations have meetings timed for Fridays at 4pm), although it will take the first three meetings with a strong chairman for participants to understand this rule. The structure of each meeting is to spend minimal time (steps 1 & 2) on reviewing the past, to allow discussion about the future (steps 3 – 6). An outline meeting structure is:

- Actions required from the previous period S&OP: 5 minutes

- Review previous period performance: 10 minutes

- Review the current plan: 15 minutes

- Identify issues and possible actions: 15 minutes

- Agree actions and sign-off the plan: 10 minutes

- Review the meeting for process improvements: 5 minutes

The pre-executive meeting is for the direct reports to the executive team members to resolve issues from each of the review meetings. It is also where Finance provides inputs, concerning revenue, margins and cash flow, based on the period’s review meetings. This meeting allows the plans, trade-offs and issues to be accepted and packaged for the S&OP Executive meeting.

The senior management team attends the S&OP Executive meeting, with attendance and participation a part of each manager’s performance. If the P&L responsible manager is unable to chair the meeting, it is rescheduled. No substitutes are allowed, as it can become a habit and the implementation will fail through lack of commitment. At the S&OP Executive meeting, the team ‘signs-off’ the S&OP; therefore, taking responsibility to rectify notable variances against the plan. This reduces the ‘finger pointing’ and recriminations so prevalent within businesses planned in silos.

To ensure that meetings do not become focused on individual products nor ‘bogged down’ by data, the S&OP process uses aggregated data, based on product ‘families’ and their processes:

- The number of families varies between 5 and 15 (preferably a range of 6–12)

- Output governs what a business can sell; therefore ‘families’ are based on the capacity and capabilities of resources within ‘Operations’. In some circumstances, families may reflect the few major customer’s brands or models, such as when supplying to automotive assemblers

- Sales forecasts by product line or group are summarised by market segment/territory and SBU/division totals. Within a product family performance, allow a sales variance of (say) +/- 5 percent from the weighted forecast. The forecasts are linked to the S&OP families.

- Structure the Bill of Materials (BOM) for each product line to ‘roll-up’ into their ‘family’ within the ERP system

- Output capabilities are expressed in a standard unit of measure that correlates with the constraint resource e.g. tonnes, shippers, litres, hours, pallets.

- Inventory at the nodes is reported by form and function for the respective families

- S&OP plans are reviewed by product family, using the common unit of measure. This provides a consistent communication base across all functions and entities

- S&OP production plans by family become inputs to the Operations planning tool (Master Schedule or similar term) in the ERP system. To reduce uncertainty in supply chains, the ideal situation is for the Master Schedule to become input to the suppliers’ S&OP process and those suppliers do the same for their suppliers

S&OP is not a software driven process. However, to be effective, the S&OP process requires accurate and timely input data. Over time, a simulation application can be acquired or developed to enable modelling of alternative plans against constraints in the markets and business. But first, the people and process elements must be addressed; an organisation must walk before trying to run with technology ‘solutions’.