Data has value

Your organisation’s data is mainly generated within Operations, of which the Supply Chains group (Procurement, Operations Planning and Logistics) is a major contributor for planning, scheduling and execution activities. However, without trust in the data there is a loss of value.

But businesses of all sizes and in many locations are increasingly trusting their data to the care of external parties. While this is justified on the basis of reduced costs, there are risks attached. Recent examples are:

Artificial Intelligence (AI) is promoted as the latest saviour for business, providing magical answers in the blink of an eye. But the answers provided by AI are often inaccurate. Recently, the company OpenAI admitted that “the system sometimes guesses when uncertain, producing plausible, yet incorrect statements, instead of admitting uncertainty”.

Machine learning (ML) within AI is probabilistic – it learns from new data and identifies a projected probability of accuracy. AI is therefore not ‘reliable’; but it is not trying to be accurate or true. And there must be an answer, even if it is wrong – these are ‘hallucinations’, which appear to be intrinsic in the way that AI works.

An example was recently illustrated by the Australian office of a global consultancy firm, which admitted to providing a large report for a client produced using genAI. The report was found to contain numerous inaccuracies and fake citations, including a made-up quote from non-existent paragraphs in a court judgement. The ‘corrected’ version of the report was also found to include AI generated mistakes. Although the firm was required to repay a large proportion of their fee, this episode illustrates the potential for a lack of trust, not only of consultants but of outputs from genAI.

Cloud Computing risks were also highlighted this month, when a major provider of cloud services had a systems failure at a data centre in the north east of the US. Although the cloud is pictured as being decentralized, a large portion of provided services rely on data centres in a few regions. With many enterprise IT systems integrated into cloud platforms and services provided for third-party applications across industries, a failure can cascade across multiple dependent services. A disruption then becomes a global problem.

With a very high number of of user companies in the cloud, the question is not whether outages will occur (that trust question again), but the damage and cost of recovery incurred when they occur. The system failure described highlights the importance of resilience plans, but there should also be questions about the value of your organisation’s data and where it should be processed and stored.

Data is the lifeblood of Supply Chains

While the aim of the Supply Chains group is to provide Availability of products and services for customers, the objective is to be Effective in serving customers. To be effective requires that Planning and Scheduling are differentiated:

- Planning is tactical. It requires a willingness by different groups to collaborate. This enables a common understanding about the future, and agreement on preferred outcomes

- Scheduling is operational. It is concerned with any resource that can affect productive output (i.e., machines and their fixtures, people and supplies) and therefore requires a detailed schedule of use, with access to current data for analysis

For many years, sensors and instruments have been available for measurement, tracking and analysing internal data to improve the Execution phase of supply chains. The latest equipment for collecting warehouse and distribution data in real-time is smaller, faster and cheaper but essentially does the same job, so is proven. As is the development of data analytics using the gathered data, not guessed or assumed. It enables predictive models concerning potential product and material stockouts and alerts concerning operational capacity shortfalls. This indicates that data has value above the cost to analyse.

Operational Technology

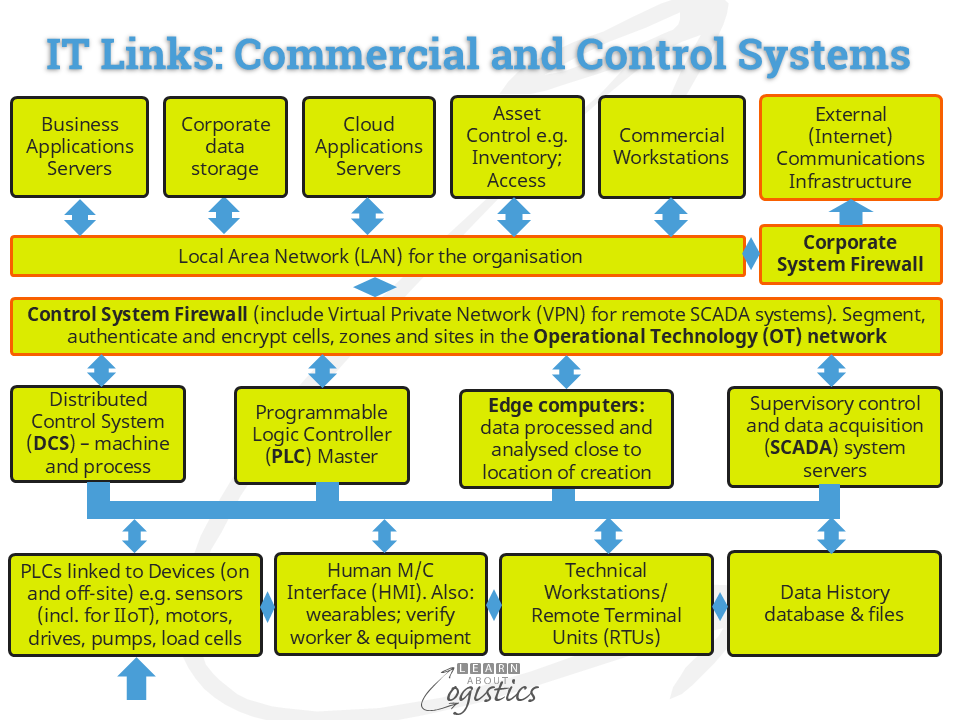

The diagram illustrates the linkage in a business between the commercial IT network and operational technology (OT) network. This framework can be used to support the premise that supply chains data can remain on-premises. For example:

- Core supply chains data for ‘line of business’ ERP systems remains on-premises

- Supply Network Analysis and Planning (SNAP) applications used for planning (e.g. Sales & Operations Planning (S&OP)) remain on-premises

- SNAP analysis applications are resident on Edge computers. Local processing and storage of data, with caching of consolidated data for timed forwarding to data centres on a ‘need to know’ basis for Software as a Service (SaaS) applications. The data and solutions are not stored by the cloud services provider

As the number of Industrial Internet of Things (IIoT) sensors and other devices increases, the real-time processing of large volumes of ‘instant’ supply chains data will need to relocate to the edge of each network. Edge Computing is complementary to the Cloud concept, providing the buffer between data collection devices, computing hardware and Cloud services. Four levels of Edge Computing infrastructure have been identified:

- at the device (e.g. warehouse equipment);

- small number of servers (e.g. loading dock);

- small data centre (e.g. a warehouse);

- mid-size data centre (e.g. multiple warehouses on a single site)

5G communication services (‘cloud-native micro-services’) is enabled to run on Edge servers. This allows for the provision of at least two types of 5G services:

- When low power consumption is required, but low latency and high reliability are not critical. An example is large numbers of IIoT devices talking to each other and to Edge computers, such as at a tank farm equipped with sensors e.g. flow meters and load cells

- When low latency and high reliability are essential. IIoT devices that require data for 30 seconds or less, with a response time of under 10 milliseconds. An automated distribution centre is an example.

The 0G (Zero Generation) network is designed for sending and receiving non time-critical small messages over a long distance. It is a low-bandwidth wireless network designed for basic, low power and low cost IIoT devices to connect via the Internet. For example: use in condition monitoring (temperature/humidity/time) for short shelf-life items in containers and trucks.

While there is much emphasis on reducing delays in supply chains, there is an equal requirement of trust in decisions. There are too many examples of errors from using AI and a potential of increased risks from only three global suppliers of cloud services. To increase trust, businesses must consider whether it is preferable to have critical supply chains data stored and analysed on-premises.