A major change

Although circumstances around the world are always changing, there are periods of time when more dramatic change occurs. Such a period could be now, with ‘Globalisation’ as a geopolitical objective being replaced in some countries by ‘Nationalism’ and ‘Security’.

Articles and podcast express concern about the increasing uncertainties in the world that could affect commercial decisions in some businesses. These include aspects of supply chains, such as locations for purchases of ‘critical’ materials and if inventory should be held on a ‘just in case’ basis. But supply chain professionals must have the resources (including time) to gain an understanding of the many uncertainties and whether any control can be exercised over them.

Uncertainties in Supply Chains

Over the past fifty years, there have been changes in trade policies and taxation rules by governments, transport infrastructure and communications capability that have changed investment expectations. These have influenced operational decisions by businesses in developed countries, such as:

- Increased the number of ‘stock keeping units’ (SKU), to provide product differentiation across smaller market segments – identified as the ‘long tail’

- Outsourced ‘non-core’ functions and contract out individual activities

- Sourced globally for materials, components, intermediate parts and finished products

- Located production operations offshore in low-cost countries (LCC)

Through implementing these initiatives, there has been an increase in Uncertainty in supply chains due to an increased:

- reliance on a global spread of outsourced suppliers

- number of Nodes and Tiers (levels) of suppliers with increased specialisation

- number of direct suppliers (Tier 1) at Nodes in the network due to outsourcing

- lead times for items, due to longer delivery distances

- Variability in inbound lead times and product sales patterns, requiring increased safety stock

These nine factors can interact and amplify each other. This increases the likelihood of disruptions in the supply and distribution of items across national borders and across Tiers of suppliers in different industries and countries. Uncertainty is also increased when an organisation is willing to accept:

- A focus in operations on speed and efficiency rather than being effective through the supply chains. If too much responsiveness is required by a powerful buyer, the result can be Instability

- A low redundancy or safety margin when planning Operations at the S&OP tactical level concerning lead times, inventory and working capital

- Accepting increased complexity within the Flows of items, money, data and information through supply chains, because Flows are Non-linear, with many ‘ifs’ and ‘thens’, as in a Decision Tree diagram

- A lack of knowledge concerning where Power is exercised (through ownership, control or influence) among the Nodes and Links of the organisation’s Supply Chains and the uncertainties associated with Dependency. The response to a disruption may be influenced by Power and Dependency, such as the allocation of scarce materials

Through supply chains, there are four sectors in which uncertainties can occur:

- Supply Chains Network Design of your organisation’s Core and Extended inbound and outbound supply chains

- External to the supply chains from interactions between a location (an inventory Node or transport Link) and the wider environment. These uncertainties can be summarised under the PESTEL acronym: (Geo)-Political; Economic; Social; Technological; Environmental and Legal

- Internal to an enterprise, such as internal complexity within your organisation

- Internal to the Supply Chains group core functions, comprising Procurement, Operations Planning and Logistics

An additional source of Uncertainty is that interactions between businesses in a supply chain are Emergent, due to the unknown actions and reactions by each business to known or perceived events. The management of your organisation has little prior knowledge of or control over these actions.

The underlying business drivers of Uncertainty are Complexity, Variability and Constraints, which have been discussed in the most recent blogposts. These exist externally at Nodes and Links of the Supply Chains and internally within your organisation. However, rather than focus on these drivers of Uncertainty, most enterprises focus on reducing costs, by making their supply chains ‘lean’, eliminating redundancies and reducing inventories. But this approach increases the importance of some Nodes and Links in the supply chains, with a few becoming critical.

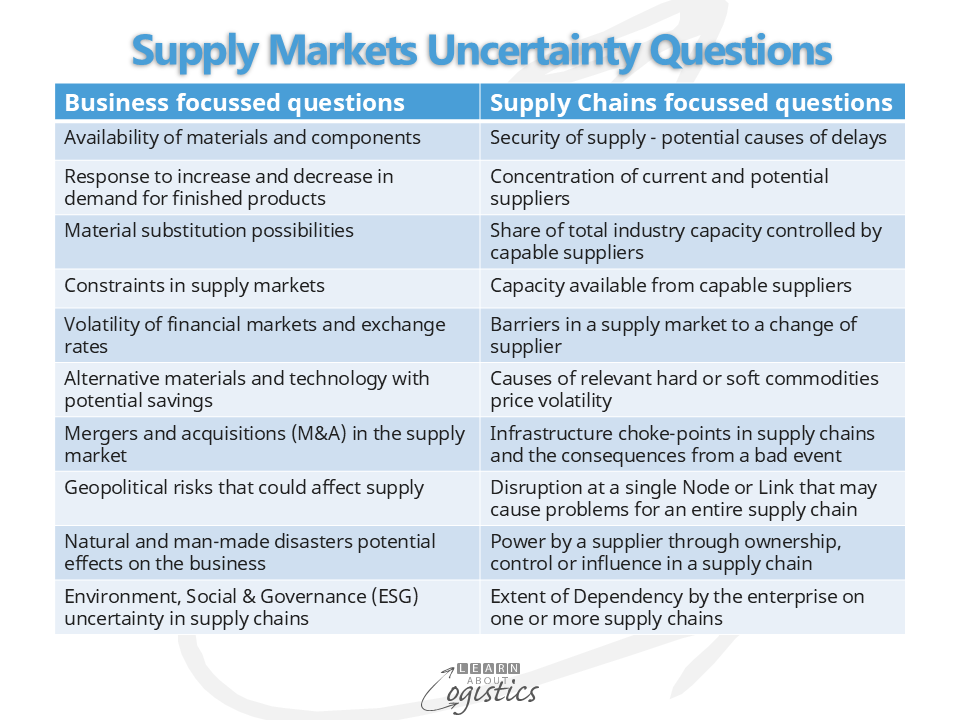

The table below identifies the type of questions concerning Uncertainty about possible events:

To understand and where possible, manage Uncertainty in supply chains should be a core responsibility of the Supply Chains group. It is one of three processes by which the performance of an organisation’s Supply Chains group should be measured:

- Availability is to enable the provision of goods and services for customers: achieved through the Sales & Operations Planning (S&OP) process

- Delivery of goods and services to customers: measured by the probability of achieving Delivery in Full, On-time, with Accuracy (DIFOTA)

- Uncertainty is minimized through the organisation’s supply chains by using a Risk Management process

Uncertainty to Risk Management

Should an organisation continue without answers to the questions above, or can something be done to reduce the consequences? Uncertainty is a person’s unstructured opinion, with a lack of predictability concerning the cause and effect of an event. However, an Uncertainty can become a calculated Risk when a future event is structured to identify the likelihood of the event occurring, together with the likely consequences if the event occurs.

Supply Chains are uncertain because, as noted, organisations do not have control over the activities of commercial parties in their supply chains. But, you can address uncertainties in supply chains, to better understand the vulnerability and resilience required for critical events, such as: a virus outbreak, trade disputes, climate change, or interruptions at a supplier or infrastructure facility. It is through building a Supply Chain Risk Management (SCRM) process as a part your organisation’s Supply Chains strategy and which complements the Sales & Operations Planning (S&OP) process.

However, the greatest risk is that an organisation remains in reactive mode and only responds when something goes wrong in an economy or its supply chains. Not investing in processes, techniques and technologies to protect against anticipated risks in an organisation’s Supply Chains is not an effective way to saving costs.