Supply Chains flow

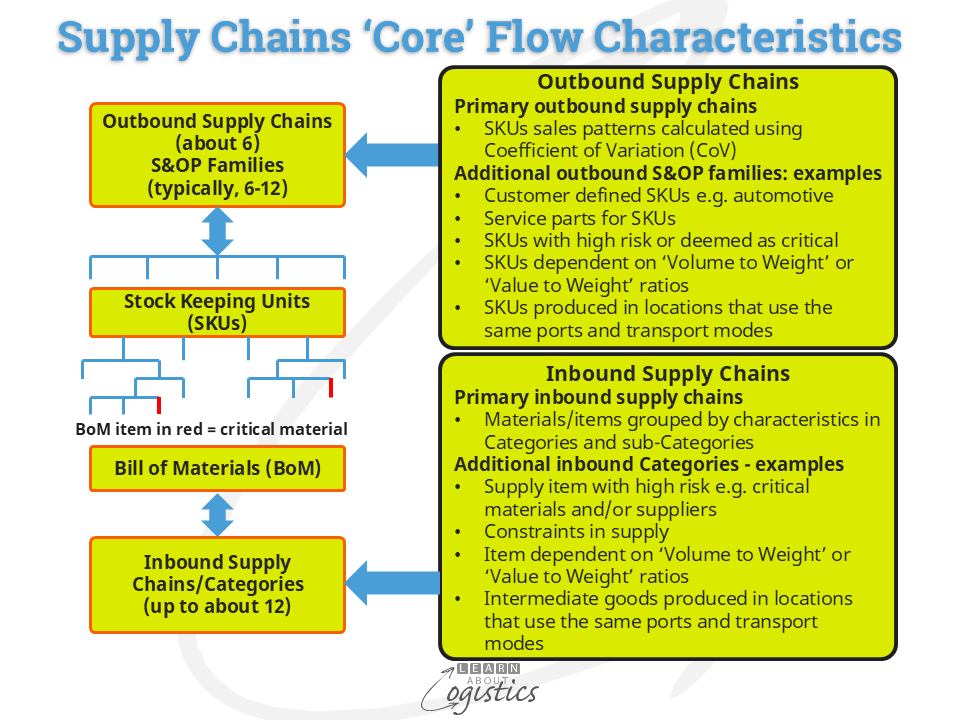

Through an organisation’s supply chains, there is a flow between the outbound supply chains, the Sales & Operations Planning (S&OP) process and inbound supply chains. The connection between them is the Bill of Materials (BOM) for each stock keeping unit (SKU) and exploded into their respective components and materials for purchase.

The diagram below illustrates the flow through the ‘core’ supply chains, from Tier 1 customers to Tier 1 suppliers and where BOMs fit in the flow. This helps to develop production schedules, plan labour, arrange purchases and other operational tasks, such as to schedule equipment maintenance. BOMs are primarily used by engineering/technical, planning and scheduling, inventory and procurement, with Sales involved where customised parameters and product options are available.

Types of BOM

A single level Bill of Materials shows the SKUs available for sale and is used by importers and wholesalers of finished products. It may also be a single layer list of the components and materials used in the product. Another single level BOM is the engineering bill of materials used in the design of a product. It is a list of all parts, components and materials for the finished product and may also include technical specifications for materials or drawings for parts in the manufacturing BOM.

A manufacturing bill of materials (MBOM) is the structure used for complex assemblies to produce a finished product for sale (an SKU). This is a hierarchical tree structure, showing the parent-child relationships through cascading levels between the SKU, formulas or sub-assemblies, components and materials. The depth of this structure is dependent on the investment in and capability of production.

An MBOM includes a description of the equipment and tooling required through production. Also production routing and cycle time, setup time, work processes, inbound lead time and production time. These help to determine when to acquire purchased items and when to start production of a product’s sub-assemblies. In a process business, there will be factors about waste that provide input for by-products and co-products.

A version of the manufacturing BOM is the Configured Bill of Materials (CBOM). This is for situations where the production of products can be customized to meet customer requirements, for variations in parameters or to include optional features. The structure of a CBOM allows these manufacturers to manage a range of product configurations without providing separate BOMs for each variant. The modular structure provides for parameters or options to be configured into a product, which allows the creation of different product versions while sharing common sub-assemblies and components.

Configured BOMs are used in businesses that are Make to Order (MTO) or Assemble to Order (ATO) where Marketing or customers can specify a range of parameters or options. This can range from metals job shops and machinery production (e.g. size of industrial fan motor and blade within a standard base) to apparel (size, colour, fit), automotive options (colour, trim and power train) and furniture (head height, leg type, firmness and cover material). Another CBOM situation is where the same product is produced for customers’ brands. Here, the core product and most production is the same, but final assembly differentiates the product for each customer. This will include different packaging, container volume or unit count and other modifications that make the product suitable for the customer’s market.

When parameters within products can be customised, it often requires different or longer routing through one or more facilities, therefore affecting lead times, which influences the delivery date. This requires the creation of an attribute range for each customisable part and the expected demand percentage at each affected production step. Options however, are usually a substitute of one module for another, which are either made in-house or purchased. This requires a forecast of likely preferences, expressed as a percentage of SKU sales for that product. Collaboration between Operations Planning and Sales is required to provide a forecast for each module, based on an analyse of previous attribute/option preferences by sales region and possible influences on future demand. When the MRP is run, the percentages of forecast sales are calculated for each parameter or option.

Software for BOM

BOMs structures are typically included within the MRP module of ERP systems and contain data analysis, error checking, change management and version control. There needs to be a facility for customising data fields, to enable features to be identified (such as a critical material) and linked to a supply chain and S&OP family for use in S&OP. Also, a capability to translate the SKU measurements (weight, volume, packaging etc.) into the standard unit of measure used for S&OP (tonnes, litres, standard shipper etc.).

Tactical Planning requires data structured in the aggregate, while Operational Scheduling requires the BOM for each Stock Keeping Unit (SKU) as the base input for Materials Requirements Planning (MRP). Although the output from S&OP is aggregated by product family and period, the BoM structure means that gross numbers can be disaggregated back to individual SKUs, based on historical sales percentages. This should enable the Plan from S&OP to be entered into the S&OE Master Schedule as a forecast for the applicable future periods.

The BoM requires the ‘quantity per’ for each supplied material and intermediate good, so the S&OE material requirements can be calculated from the Master Schedule and should be input input to the Procurement Category Management process.

Responsibility for BOM

There are different opinions concerning who is responsible for the ongoing management of MBOM. On the basis of who hurts the most if BOMs are wrong, it should be Operations Planning that is responsible. Managing the BOM library has challenges. Even if the original manufacturing BOMs are automatically generated from the engineering/technical BOM, subsequent updates and changes are likely to require manual data entry, which may contain errors. These can extend to part numbers (meaningful or random generated), part names and description and unit of measure.

Changes will include parts and materials upgrades and substitutions for late supply, packaging design, drawing revisions and production processes. The volume of change requires a regular audit to track revisions and changes, based on version control that provides a log of the changes. If a business has a Supply Chains group, the audit can be done by Procurement and Logistics, as they have an operational interest in the accuracy of BOMs.

The BOMs in your organisation are not a ‘set and forget’ item when a new product is released. They are a living document that is essential for implementing Sales & Operations Planning and the lubricant for enabling the planning and scheduling flow of your organisation’s supply chains.