Define your supply chains

Your organisation’s Supply Chains Network will not become an ‘integrated’ system, as it comprises independent organisations with their own business objectives and policies. Instead, the requirement is to build knowledge about the Network and supply markets on which your organisation relies. The recommended approach is to Map your organisation’s supply chains.

Supply Chains are defined by Tiers of supply for inbound items to the business and outbound products distributed to customers.:

- Define the outbound supply chain for a product (or more likely, a product line or group) through each Node location of that supply chain, from the Tier 1 customers and downstream to their known customer’s and on to end customers or consumers

- Define the inbound supply chain for each purchased category of items, through each Node location of that supply chain, from the Tier 1 supplier and upstream through Tier ‘n’ suppliers until there is insufficient data

- As defining inbound supply chains becomes progressively difficult, the focus changes to gather intelligence about the supply market for each ‘critical’ material (as defined by the business)

A readable academic paper provides an extensive coverage of the mapping topic, with the discussion ranging from what the authors call Global Value Chain Maps through Supply Network Maps; Supply Chain Maps; Value Stream Maps to Process Maps used inside a facility. However, the approach used by Learn About Logistics has the second level name changed from Supply Network Maps to Supply Markets Intelligence, as this provides a clear difference between the objective of the activities. In this case, what the authors name as Supply Chain Maps can include all Nodes in the Network. For lecturers, the paper provides examples of maps at each level, together with diagrams that can be downloaded.

Supply Chains Design Map

The Map traces input items to the sites where they are produced or handled, which is called ‘part-site’ mapping. This enables your organisation’s Supply Chains group to quickly know which intermediate goods, parts/components or materials are likely to be delayed by an event that has or may affect a specific supply chain, physical site or input item.

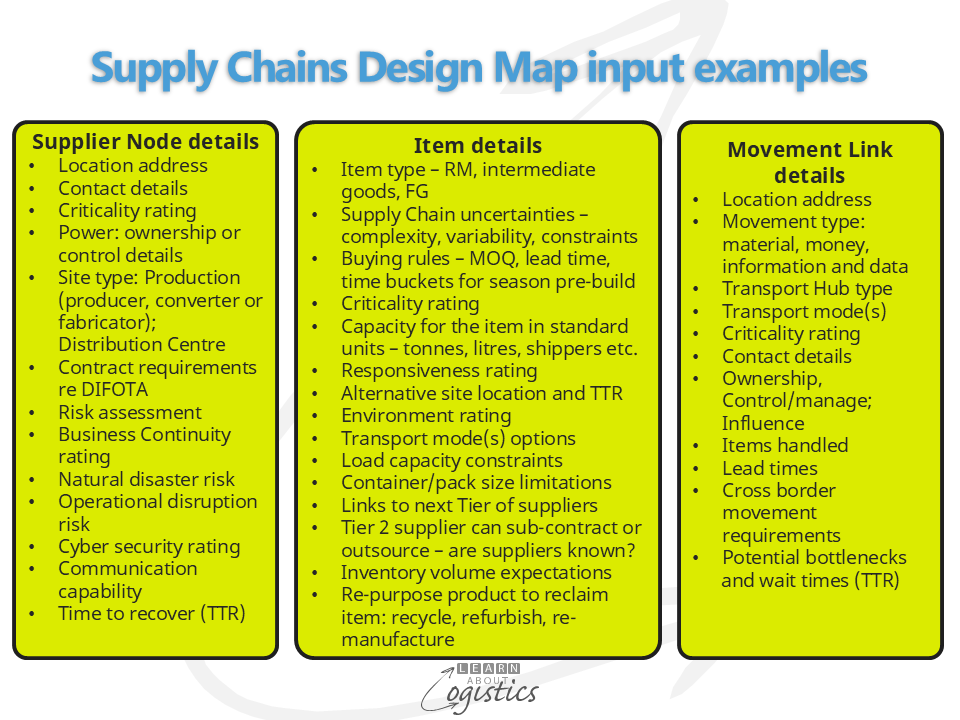

The model for a supply chain has a collection of Nodes that directly participate in the production of physical items within a supply chain. Also, Links which identify how the participants in a supply chain are connected. This information is used at each Tier of a supply chain. The diagram provides examples of the most common factors to build an effective Design Map.

The Supplier Nodes and Movement Links relate to physical sites and include the Logistics Services Providers (LSPs) that own, control or influence critical Links. The ‘Item details’ refers to the availability of a ‘critical’ (as defined by the business) material, component, intermediate good or finished product. The data will need to be collected, as the corporate IT system is unlikely to store the location and operational details of the supplier’s factories and LSP distribution facilities.

For outbound products, the Design Map has Logistics and Sales working together. It incorporates details of customer’s locations and customer’s customers where required (maybe for service parts distribution). In addition, is the Sales Markets (or Channels of Distribution) Segmentation Map, which identifies Order Qualifiers and Winners and Customer Service expectations for each sales market.

Developing Supply Chain Maps from primary sources can be a long process, which requires a collaborative relationships with Tier 1 suppliers and customers (the Core supply chains). This will speed the process and enable the collaboration of Tier 2 and on suppliers and customers (the Extended supply chains).

Supply Markets Intelligence (SMI)

The supply chains of consumer businesses in CPG and FMCG sectors tend to have inverted ‘V’ shape supply chains. There could be competitive suppliers at Tiers 1 and 2, but at Tiers 3 and 4 and more, there could well be hidden dependencies, where all businesses at a higher level are dependent on a single source for a critical ingredient. However, brand companies selling finished products can be unaware of this situation, as they only deal with suppliers at Tier 1.

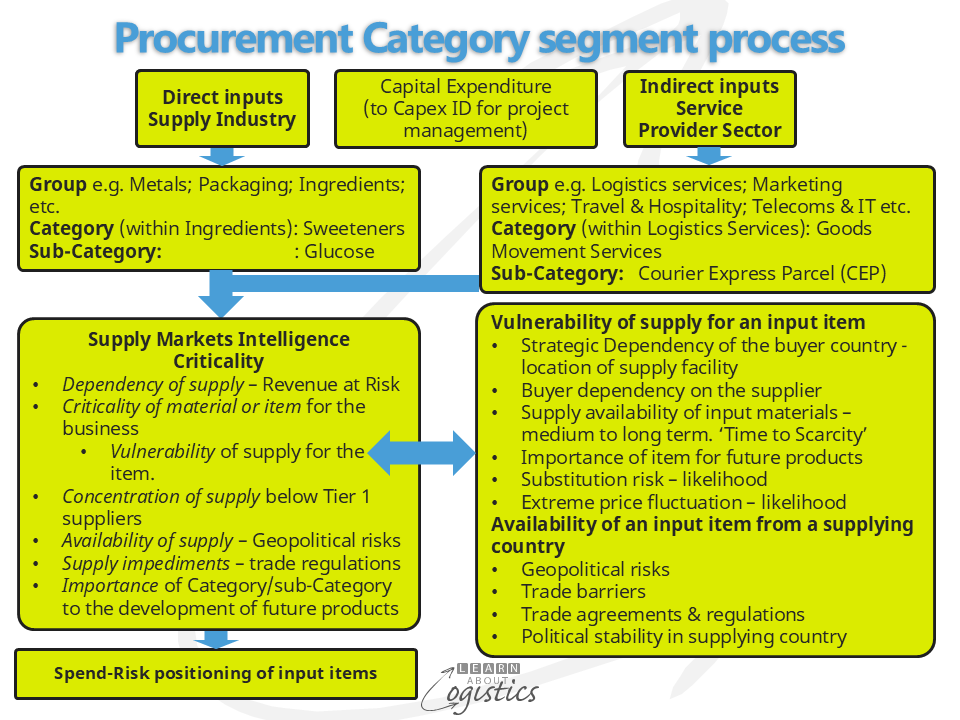

While a comprehensive mapping of supply chains would identify the potential challenge, the complexity of supply chains means that a complete mapping of each supply chain is unlikely. Instead, supply chain professionals must rely on an understanding of supply markets for input items that are identified as ‘critical’ to the business. The diagram illustrates the process.

The technique is to utilise the Category Management capability used in Procurement. Input items at Category and sub-Category levels, plus ‘important’ materials that are embedded in purchased intermediate goods are considered. The unit value (or even annual spend) for an item is insufficient as a measure, because an event can equally affect the supply of an item costing 10 cents or $100. Supply problems have shut factories caused by shortages of supposed minor items such as adhesives, coating for metal cans and an ingredient in confectionery.

Under Criticality, each of the six headings has a score entered that indicates whether the business is open to disruption from this heading. The total score is the Criticality for that Category or sub-Category of supply. Items with high scores are ranked into a Portfolio within the Supply Chains Risk Management process for mitigation and adaptation actions.

Responsibility for the Supply Chains Network Design Map and Supply Markets Intelligence belongs to Procurement. This is because it is the organisation’s manager of external risks, which helps protect the gross margins of the business. To identify and understand the risks associated with the purchase of an item requires Procurement to understand the wider risks associated with the organisation’s supply markets, and so be able to take advantage of current and impending situations.