Integration is not advised

The tight integration of systems and data is promoted as enabling a more effective organisation. However, as an organisation becomes more tightly linked, there is an increased risk that systems become fragile and something will break when events in supply chains generate Uncertainty (derived from complexity, variability and constraints). Too much structure and integration can result in a lack of agility to respond to changes in the wider environment.

The previous blogpost discussed the proposition that Finance and Supply Chain groups should have integrated data to “accelerate the decision-making process and enhance the organisation’s resilience”. The conclusion cautioned against integration. Instead, it recommended that critical interfaces and associated data requirements be identified and to signal abnormalities in patterns. This improves inter-operability between the two processes and enables a closer working relationship that could derive benefits for both groups. This can also apply to other working relationships in a business.

Change thinking about supply chains

People in business are more likely to imagine supply chains as linear flows, instead of a complex, adaptive system. Therefore an expectation that Operational plans, with ‘accurate’ ERP data, can be integrated with other plans. Instead, supply chains must be recognised as a process to provide value for end users at the lowest total cost. To provide value requires an effective flow of items, money, information and data from the sales channels through the organisation to its Tier 1 suppliers (that includes contract manufacturers and logistics service providers (LSPs)), but in an uncertain environment.

For the supply chains process to work requires skilled and knowledgeable people assigned to functions that identify what they do. The Supply Chains group consist of at least Procurement, Operations Planning and Logistics. The Aim of the Supply Chains group is: To satisfy the needs of customers and end users through providing Availability of products and associated services through the time-related positioning of internal and external resources, at the lowest total cost.

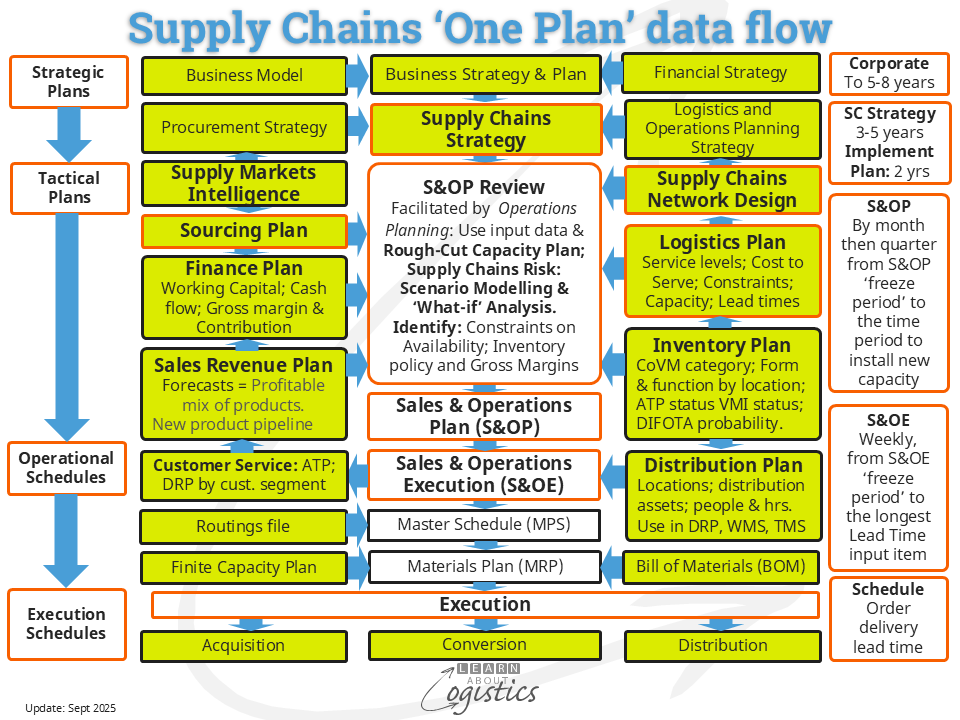

To achieve the Aim requires the planning and scheduling of Operations, which entails collaboration between the Supply Chains group and other departments, to enable consensus decisions. The factors that most influence planning of supply chains are: lead times, capacity, flexibility, service levels and cost, with sustainability becoming more important. For the initial co-operation to be effective requires a unified data model, with the diagram illustrating the type of data flow required to enable a ‘One Plan’ approach for an organisation’s supply chains.

‘One Plan’ assists providing Availability

Supporting each of the Plans in the ‘One Plan’ is data and information that informs the critical demand and supply activities. This is not a technology driven exercise, but is to understand the process of Flows through the supply chains.

For example, although there is much written about ‘end to end’ supply chains, the term is never explained. But the term appears to extend from Tier 1 customers through the organisation to its Tier 1 suppliers. These are the ‘core’ supply chains. From Tier 2 customer and suppliers are the ‘extended’ supply chains of a business, of which little is usually known. Even for an organisation’s ‘core’ supply chains, the physical location and associated risks of Tier 1 suppliers may not be on record, yet businesses are more dependent on suppliers and functions that have been outsourced.

As an organisation grows, the variety of options concerning Operations increases, which creates additional complexity for internal interactions. Add this to increased uncertainty about the wider environment that can affect an organisation’s supply chains, requires internal processes and systems to be more flexible in their structure.

Reviewing the diagram, the Plans are shown for the respective function and as input to the Sales & Operations Plan (S&OP), which is the ‘heart’ of a business or profit centre. As the title says, S&OP is the outcome from collaboration concerning trade-offs between Sales (the demand side of an enterprise, which includes: Sales, Customer Service, Marketing, Product Development and Demand Planning) and Operations (the supply of products and services for sale. Includes the Supply Chains group (Procurement, Operations Planning and Logistics); Manufacturing/Production and Technical/Engineering). Finance evaluates the proposed plans for their effect on working capital, cash flow and profitability.

S&OP connects the flows of items, money, data and information through supply chains with the Demand flows from Sales. Included are the customer service operating requirement, which is the Available to Promise (ATP) level of service for customers, based on the Availability policy of the Supply Chains group. This requires a link between the Sales Revenue Plan and Logistics Plan to identify patterns in distribution capability, production or import shipping capacity and information technology availability. S&OP also connects the workflows of Procurement and Logistics. Supply Chain Insights provides some additional interfaces to be considered that enables inter-operability between functions:

- Logistics Plan data links into Operations Planning to reflect lead times and cost patterns that may influence product availability

- Measure the pattern of outbound product flows to understand the buying patterns of downstream customers. That is Logistics data used as a substitute for demand data

- Identify the critical data sets in the Distribution Requirements Planning (DRP) and Transport Management System (TMS) applications to extract data and analyse for patterns that can affect performance of each function

- Link Available to Promise (ATP) with Customer Segmentation and SKU Allocation (fare shares) rules

On the right side of the diagram is the criteria governing the planning pattern for each stage. For S&OP, it is shown as ‘by month then quarter from the end of the S&OP ‘freeze period’ (which could be two months), out to the time period to install new capacity’. As the facilitator of S&OP, the role for Operations Planning is to define future actions for product ‘families’ as a response to patterns of behaviour, shown through trends and indicators.

So, Operations Planning is not a ‘real-time’ exercise, with data being accurate to four decimal places. The main interface required between S&OP and function plans is a pattern recognition capability that analyses incoming data and transmits information concerning abnormal patterns into the S&OP process.