A systems failure

On April 28, millions of people and metro systems, airports hospitals and communication systems across Spain, Portugal and parts of France were affected by an unexpected power outage. Across Europe, the aim is for an integrated electricity system, but what about small events far away that can quickly escalate into serious emergencies, without national governments being aware?

Although power was restored, the blackout sent a message to governments and populations about the downsides of their reliance on power. The European electricity grid system has reported a system failure at inter-dependencies in the grid. A fire in southern France damaged a high-voltage power line, which caused a grid oscillation in Spain that triggered a failure in the interconnector with France, which caused the interconnector with Portugal to also fail.

So it is with supply chain networks and potential failures. Your organisation’s supply chains are part of a network of suppliers on which the business is reliant. But, an event with little warning at an unknown supplier at Tier 3 or 4 in one supply chain, or at a Logistics Services Provider (LSP), can have unexpected and adverse consequences for your organisation.

Resilience is not new

The consulting firm McKinsey states that “in a crises, half the impact arises from the crisis itself, while the other half, good or bad, is determined by the response”. The response by a business to an event is governed by the Resilience built into the ‘core’ supply chains, between the organisation and its Tier 1 customers and suppliers.

For a business to have Resilience is not a new idea. Identifying the variety and complexity of biological systems was researched in the 1950s and 1960s in the US and UK and likely other countries. From these studies, (called Cybernetics in the UK), one of the outcomes was the Law of Requisite Variety, which in a simplified form stated To control your destiny, be more flexible than your environment. For a Supply Chains Group (Procurement, Operations Planning and Logistics), the environment is their organisation’s supply chains network, which is a complex adaptable system.

In this system, each supply chain Adapts to a new situation over time, as independent entities at the Nodes and Links of each supply chain respond to changing situations, based on their own interests. The outcomes are Emergent and Cumulative and cannot be predicted with any certainty, as they are influenced by the external environment, over which the management of an organisation has little control.

Therefore, a Supply Chains Group must be capable of recognising and absorbing a variety of information about changes in the supply chains and the surrounding environment. For example, about supply markets, supplier strategies, logistics infrastructure changes and 3PL innovations. And in response to new scenarios, are able to adapt strategies and the provided services.

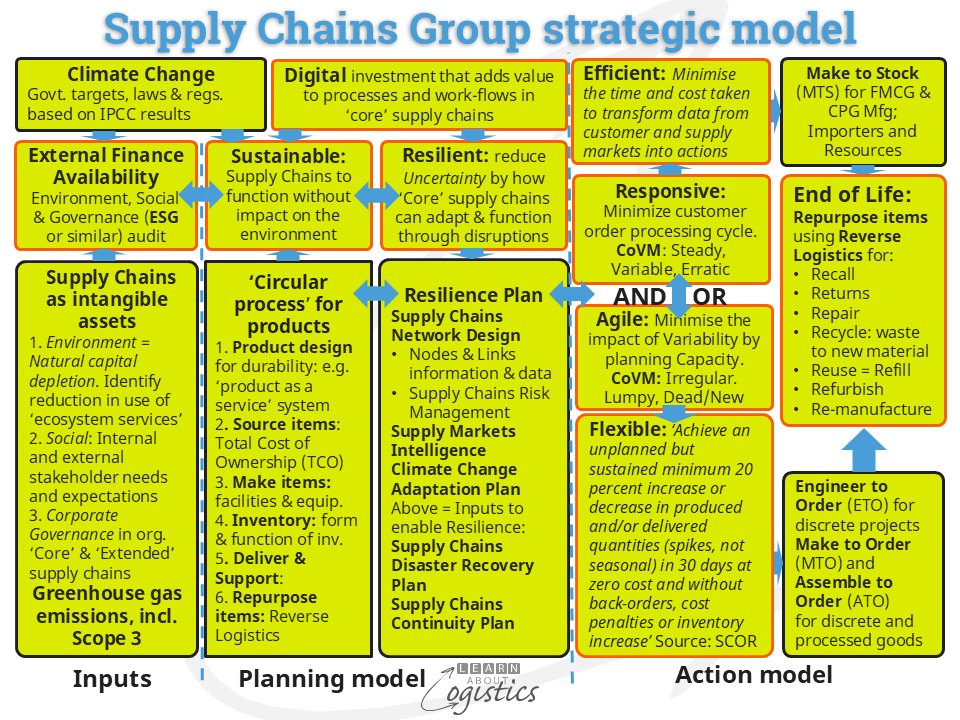

The more Uncertainty in the supply chains operational environment, the more agile and flexible must be the organisation and its internal systems. If an organisation’s IT systems and teams have too much structure and integration, then the business will not be sufficiently agile in its response to changes and events. As shown in the diagram, businesses need to be more Resilient.

To be Resilient

Resilience is defined as: ‘the ability to deal with adversity, withstand shocks and adapt as disruptions arise over time, and as customers and suppliers (and their customers and suppliers) in the organisation’s Supply Chains Network respond to the situation in different ways’. (adapted from McKinsey)

But Resilience cannot be measured against a standard benchmark, as each event and and an organisation’s relationships within its supply chains will differ. Under ‘Resilience Plan’ in the diagram, a process is listed to develop the two elements of a Resilience Plan, which are the:

- Supply Chains Disaster Recovery Plan

- Supply Chains Continuity Plan

The level of Uncertainty about an organisation’s supply chains is the product of Complexity within and between the organisation and Tier 1 customers and suppliers; Variability in throughput and lead times of suppliers and Constraints in processes. Uncertainty within supply chains will increase when an organisation is willing to accept:

- Complexity within the Flows of an organisation’s supply chains (items, money, data and information) that are Non-linear in operation, with many ‘ifs’ and ‘thens’, as in a Decision Tree diagram

- A focus within Operations on speed and efficiency rather than effectiveness. If too much responsiveness is required, the result can be Instability in supply chains

- Long lead times between the organisation and its suppliers and customers

- Low margins of safety concerning lead times, inventory and working capital

- A lack of knowledge about Power and Dependency among the Nodes and Links in the Supply Chains Network. This may affect the organisation’s response to a disruption (such as knowledge about the allocation of scarce materials)

- Power is exercised through ownership, control or influence at locations in supply chains

- Dependency is due to a reliance on a customer, supplier or supply chain

To understand and respond to Uncertainty, the factors are identified in the Supply Chains Network Design, also called the Supply Chains Map. The Map contains details of customers and suppliers at Nodes and Links in the supply chains and is completed over time by the Supply Chains Group, when information and data becomes available. As the information contained in the Map becomes more comprehensive, so the credibility of analysis will improve for Supply Chains Risk Management (SCRM).

Supply Markets Intelligence enables a more comprehensive Network Design. It provides information about the status of supply markets that may affect the operations of suppliers at any Tier of supply and which can flow through to an affected business.

Climate Change Adaptation Plan uses the outputs from the Environment, Social and Governance (ESG or similar) audit. It identifies the scope and timing of changes to infrastructure, processes, systems and people that may reduce the risks to an organisation’s external and internal supply chains.

These three elements provide inputs that enable development of plans for an organisation’s supply chains, which address short term Disaster Recovery and longer term Continuity.

Building Resilience in a business has become more critical with the increase in geopolitical tensions, together with changing demographics and demand patterns. These factors could require a more rapid response that include changes to the product and sales channel mix. In turn, this requires an increased ability to predict and prepare for changes through your organisation’s supply chains.