Supply Chains are a risk

The evolving situation with geopolitics, climate policy and finance highlights the need for organisations selling products to understand their supply chains. Not understanding your organisation’s supply chains is a risk to the business.

Understanding includes potential changes in trade patterns (or geometry, measured by: trade intensity, geographic distance, import concentration and geopolitical distance) and how it may affect shipping, port berth availability and warehouse space. Conflicts and climate change influence on weather (storms, floods, droughts) can disrupt shipping lanes and affect flows of global trade.

Surveys have indicated that even well-resourced companies know details of supplier production locations for about half their Tier 1 suppliers, about 20 percent of Tier 2 suppliers and less than 5 percent of Tier 3 suppliers. Yet it is at lower Tiers where the risks to supply are highest.

Federal organisation structure

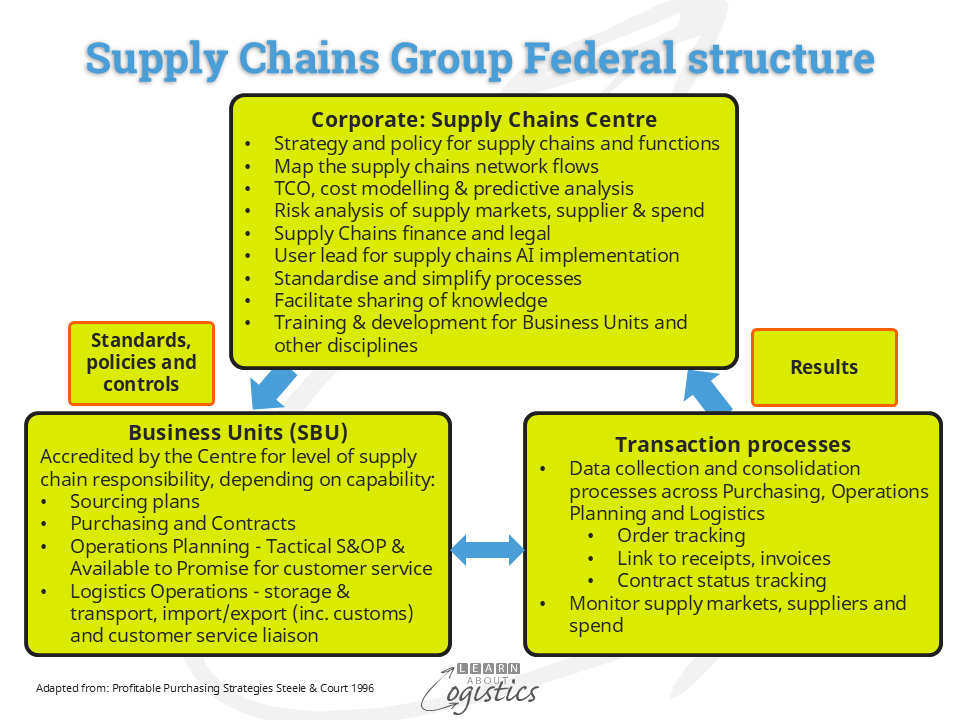

Since first publishing the blogposts, Learn About Logistics has promoted the concept of a Supply Chains Group, comprising Procurement, Operations Planning and Logistics that provides a unified approach to understanding and working with an organisation’s supply chains.

For product organisations that have multiple business units, a Federal structure is the organisation to best achieve the objective. This has a small function at the centre, which integrates strategic and policy activities and accredits operational business units to undertake the tactical and operational activities for their supply chains.

In support of this approach, a recent article by the consulting firm McKinsey notes that: “Procurement will be a strategic, centre-led function that automates processes to free up resources for category management”.

The terms used are of interest. The ‘centre-led’ concept was developed as the Centre Led Action Network (CLAN) by a UK based procurement consultancy in the late 1980s. It was designed for organisations with dispersed activities at locations within one country or across a number of countries and having local autonomy and profit responsibility. Category Management was developed in the early 1990s. This illustrates that it can take between 15 and 30 years for a new concept or technology to be widely accepted and implemented.

The article also noted that “two-thirds of the respondents report that their companies separate strategic Procurement and transactional buying activities,… with more than half supporting a dedicated Centre of Excellence (CoE) for strategic Procurement”. This structure means that the ‘doing’ of purchasing is at the local level, but activities are connected to the Centre for guidance and co-ordination. The article noted that a Centre has responsibility to:

- standardise and simplify processes e.g. approved supplier lists

- facilitate the sharing of knowledge, training and career development

- promote the discipline to senior management and the organisation

- enable analysis of transaction data and integrate into SBU processes the:

- operational insights,

- supply markets and supplier risk

- should cost modelling

- ESG regulation

- Codify, maintain rigor, and define the approach for topics such as AI, analytics and e-sourcing

Supply Chains group Federal structure

The Aim of the Supply Chains group is to plan Operations that provide Availability of finished products to satisfy the demands of customers. The plan is supported by Procurement providing Availability of input items and Logistics being effective and efficient in the receipt, delivery and storage of inbound items and outbound products. The Supply Chains group can enhance the Federal organisation structure to that shown in the diagram.

A successful Centre-led Procurement team has 3-4 knowledgeable people. Therefore, a Centre-led facility for a Supply Chains group in a multi-SBU business should be no more than 6-8 professionals, maybe up to 10. The Centre leads strategies for change in relation to supply markets, suppliers and internal processes. An important role is to accredit the business units for the extent of responsibility for their tactical and operational activities.

The governing document for the Centre is the Supply Chains Network Design Map. Inputs to the Map include:

- Information concerning each supplier location, their risks and dependencies at supply Nodes and transport Links

- Information about infrastructure and capacity at transport Links

- Supply Markets Intelligence: risks in each category supply market. Supply Markets Intelligence and Category Management can be blended, providing a more consistent development of supplier relationships

- Spend-Risk Positioning Analysis

- ‘Revenue at Risk’ identifies the potential revenue loss from Procurement risks

- Climate: emissions reduction regulations at Nodes and Links

- Environment, Social and Governance (ESG) regulations and risks, which may influence the Procurement and handling of items at Nodes and Links

The analysis of supply markets for inbound supply items includes: risk of non-supply; reliability of supply, location (of supply facilities and input materials), visibility of actions and sustainable processes.

The total cost of ownership (TCO) adds to the purchase price the costs associated with: location risks (of the supply facility), reliability of delivery (responsive or flexible), visibility through extended supply chain and sustainability. For the Centre, an aspect of reducing the TCO is to develop a more collaborative relationship with Tier 1 suppliers with a high-risk factor.

A task may be contracted or a function outsourced, but the risks are not. A risk can equally affect the supply of an item costing 10 cents or $100, which affects the business to the same extent. The ‘Revenue at Risk’ identifies the financial magnitude of supply risks, which enables a Portfolio of mitigation and adaptation actions to be established within Supply Chains Risk Management process.

For a business unit, the full accreditation by the Centre provides the flexibility to manage their own Supply Chains group at the tactical level, which is more effective. The majority of sourcing plans are developed at the business units, as most sourcing evaluations are not strategic. Tactical purchasing and contract management is managed within the business unit, but links are made with other SBU to develop group contracts and confirm supplier intelligence. Implementing the Sales & Operations Planning process is often a challenge that requires assistance from the Centre.

Although the referred survey indicated a positive development in thinking about a Federal organisation structure, other surveys in 2025 have identified that cost reduction has reverted to the #1 priority for supply chains. Experience indicates that it takes about six to ten years following implementation to fully change thinking and attitudes. Changes in management means that replacements are not necessarily committed to the change and can revert to the old way.