A Change Management implementation

A planning process is required in business because the future can be unexpected. An exploration of options and contingences must be undertaken, so that management groups are aligned to the potential outcomes and the necessary capabilities developed. A quotation that summarises this thinking comes from the WW2 general Eisenhower “Plans are useless but planning is indispensable”.

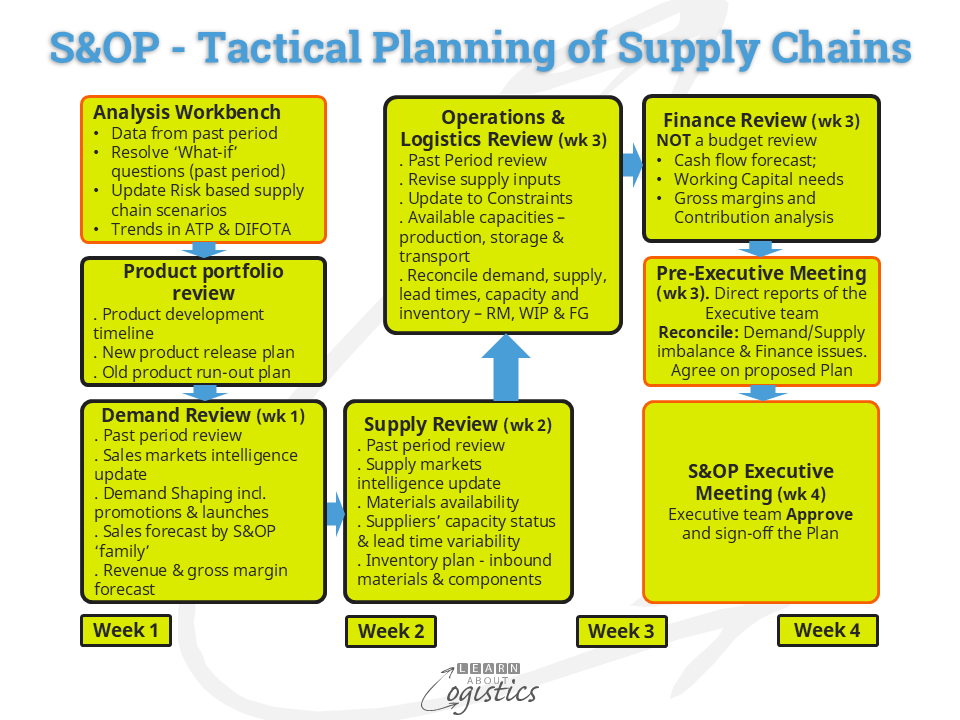

Within the operational part of a business, the planning process is Sales & Operations Planning (S&OP). The term and process was introduced in 1978, through the book Orchestrating Success: Sales & Operations Planning by Walt Goddard and Dick Ling. By the mid-1980s, S&OP had become a recognised technique for planning at the tactical level, with the diagram below providing an overview of the process.

After 40 years, only a minority of business have implemented the correct process; why is this? The research firm Supply Chain Insights notes that S&OP is 60 percent change management of an organisation’s culture, 30 percent implementing a process and 10 percent using technology. Yet, the priorities and solutions often promoted are technology based. But any amount of software will not make S&OP happen, it will only enable the process. So, could the lack of action be due to a wrong focus?

Change is not happening

When researching for this blogpost, an article written in 2006 was located. Although written 20 years ago, this article could have been written today. The author called for academics, authors, consultants and software providers to stop trying to rename or reinvent the S&OP model and making a simple process appear more complicated. He also noted that “you have one chance to get S&OP right. S&OP is a major change initiative and if you screw it up, you will find it nearly impossible to get the executive team buy-in needed to restart the process”. He wrote that the most pervasive problem at that time was a lack of reality-based planning and executive involvement. He emphasised that for success, senior executives must prepare for and attend the S&OP Executive meeting – as a signal of S&OP’s importance, the executive bonus scheme should include attendance and involvement.

The need for tactical planning is emphasised in the latest U.N. Trade and Development Report, which identifies “indicators that the global economy is transforming”… as “countries’ push to diversify export markets and production” and that “global economic sentiment remains negative. Output growth is still slowing, and the dominant trend is” prolonged uncertainty as economies (and businesses?) struggle to adjust to shifting external conditions”.

In light of these observations, the consulting firm McKinsey proposes that “companies establish strong external relationships and build resilient operations to be more flexible and react quickly, because the shifts are unlikely to be temporary”… However, while companies are said to want resilience and agility, the reality is that most flows through supply chains are reactive. To commence the change requires a strong and active S&OP process which, because the Sales and Operations groups do not traditionally work together, means that implementation takes patience and time.

Implementation highlights

S&OP provides a ‘window into the future’, so that companies can identify potential problems and realign resources. The S&OP process is discussed in an earlier blogpost, with Important points being:

- The chair of the S&OP executive committee is the profit centre manager of the strategic business unit (SBU). But do not assume an understanding of planning supply chains, so training maybe required. This enables the S&OP Executive meeting to build a collaborative environment that provides a forum to discuss and resolve exceptions to the plan and with the executive team accountable for outcomes

- There is a meeting timetable discipline, with all meetings no longer than one hour and general, non-critical data and information banned

- Output from S&OP is input to the Sales & Operations Execution (S&OE) for scheduling at operational locations

One of the challenges when discussing supply chains in a business is the lack of common definitions, especially when the term is commonly used in podcasts and articles, but rarely defined. What is a supply chain? Supply chains visibility and ‘end to end’ supply chains; variability, agile and responsive? Can supply chains be managed or only understood? What are the effective cross-function measurements for supply chains?

S&OP is company wide, but based at the SBUs, as a collaborative decision making process that is not concerned with the present. By approving the S&OP, SBU management resolves conflicts, establishes the numbers and provides the direction for all functions to work within; that is, they establish the ‘one plan’ approach to managing the business.

Another challenge for resolution is the questionable need for S&OP to be integrated with ERP systems and financials. Although transactional applications within operational systems should be integrated e.g. available to promise with warehouse management and transport scheduling, integration is not required for periodic tactical planning. As the output from S&OP is a forecast, it can be used as is an input to the budget process, but not the other way – the budget process must not constrain the S&OP process.

Planning commences from the end of the scheduling ‘freeze’ period (often in month three) out to 18 or 24 months. As a general rule, any data and information that covers the near-term horizon between 0 to 3 months, belongs in S&OE schedules, which addresses actual demand and supply.

S&OP relies on good resource capacity projections and the delay (or latency) between actions and response in the markets, and through demand, supply and internal processes. But as tactical planning is concerned with trends and probabilities to enable the balancing of forward Sales with Operational constraints, it does not depend on the highest accuracy of sales forecast. Product line forecasts are rolled up to product groups, then into the standard unit of measurement used for planning. Instead, people should see forecasting as part of the planning process, rather than as a monthly exercise in guessing.

It has been noted that a higher likelihood of improved alignment, resilience and agility occurs when the Supply Chains group (Procurement, Operations Planning and Logistics) is structured with a separation between planning and scheduling. The thinking, strategy, and planning is at the SBU and scheduling at operational locations.

For a change management implementation to succeed, senior management must set the attitude and approach for the business. When staff members hear senior management and their manager emphasising that the S&OP process is a key part of the business, they to will also prioritize S&OP.