Logistics plan elements.

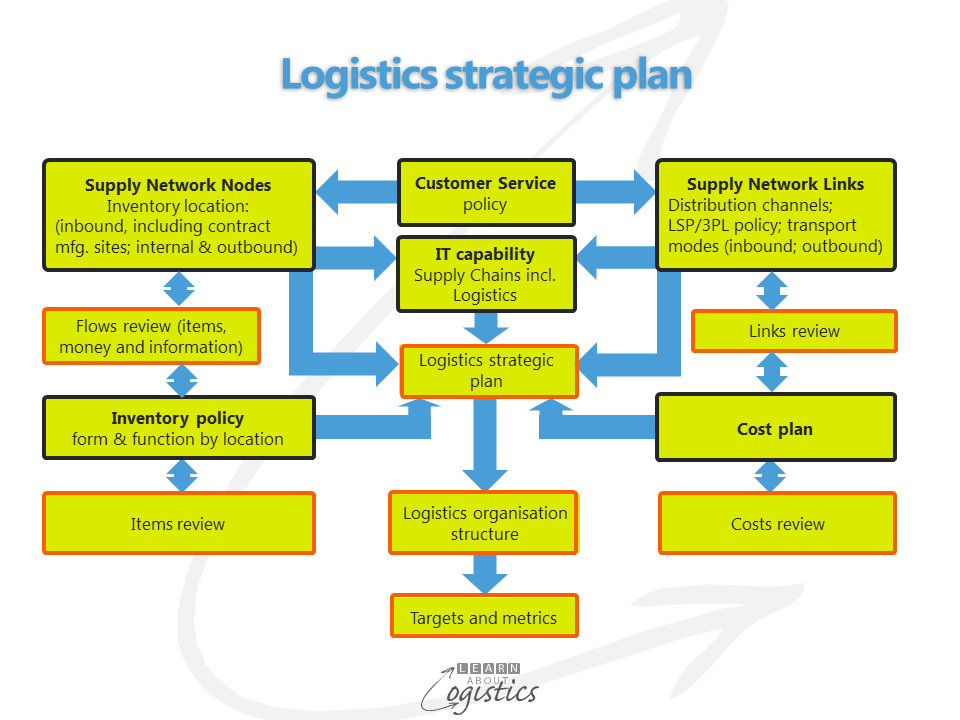

To develop your supply chain strategy, three strategic plans are required; one each for Procurement, Conversion and Logistics. Using the business model from my previous blog the Logistics strategic plan can be considered within five elements shown in the diagram:

- Customer service – the appropriate level of service for customers, by product group or segment, considering: order fulfilment requirements, enquiry and investigation capability and available information. The customer service policy informs the nodes and links of the supply network

- Supply network nodes concern inventory location – centralised or decentralised; fast and slow moving inventory in different facilities or kept together; the location of sites; use of specific technologies and layouts; use of company-owned or contracted facilities

- Supply network links concerns transport and distribution – affected by whether the company imports or exports and the size and structure of conurbations being served; transport modes, delivery patterns and storage location considerations based on the time taken for deliveries. The policy regarding Logistics service providers (LSPs), which includes third party logistics (3PL) providers is incorporated

- Inventory policy – consider the form and function of inventory at locations. This will identify the appropriate amount to hold for various groups of inventory; planning structure that links outbound and inbound materials; inventory control to be in-house or outsourced

- Cost plan – trade-off analysis between cost and service level requirements to identify the target cost of logistics operations

These elements are supported by investment made by your organisation in the supply chain IT capability.

Using these elements as inputs allows four reviews to be undertaken: flow, item, links and costs. Within the flow and link reviews, consider your outsourcing or vertical integration policy. This is the extent to which your business wants functions to ‘make’ (do something) or ‘buy’ (contract another party to do something).

The output from the reviews provides the input to the Logistics strategic plan. Within the logistics strategic plan consider each product group to identify:

- how close to markets or materials the product should be made

- where products will be made or sourced

- how products will be moved and stored

- the modes of transport to use

The main factors about products that influence the design of a supply chain are:

- Volume : weight ratio of the item

- Value : weight ratio of the item

- Availability, which reflects the lead time required by the customer or end user, therefore requirements concerning delivery and inventory

- Product security risk addresses the storage issues with items:

- Perishable

- Flammable/explosive

- High value/theft

- Contamination

The final Logistics strategic plan will identify the Logistics organisation structure required and the targets and metrics to be used for measuring the performance of Logistics.

Sustainability and the logistics strategic plan

An important element of your organisation’s future logistics strategic plan will be the sustainability of supply chains. Sustainability is underpinned by risk – what level of risk (and therefore possible added cost) will your organisation accept of the current situation before it acts to reduce any perceived vulnerability within its supply chains? This is a strategic business concern and is more than addressing government legislation, consumer concerns or employee opinions.

An example of sustainability considerations for enterprises in the consumer packaged goods (CPG) market is the term ‘food miles’, which is used to signify the distance a food item has to travel (and therefore consume energy and other resources at all stages) to find its way onto a retail shelf awaiting purchase.

Unfortunately, the media uses the terms ‘green logistics’ and ‘green supply chains’ and only considers them as the reduction of greenhouse gases (e.g. carbon) in the atmosphere. This emphasis can have the effect of reducing the importance of thinking and acting about broader sustainability strategies and actions.

Responding to sustainability opportunities requires a comprehensive business policy that considers your entire supply network. An approach that is an ad hoc collection of tactical actions designed to address a particular area (e.g. carbon reduction) will not be as effective. The strategy requires an overall statement of purpose that is the basis for an action plan within functional strategic plans.

End of year

In the southern hemisphere it is summer, so at the end of year we go to the beach. My blogs will reappear on January 6 next year. Until then I wish you all the best and an enjoyable 2016.