Who knows your Supply Chain strategy?

The Supply Chain strategy of your organisation could be a hidden surprise to most employees or even managers.

To understand the situation, consultants with a brief to identify improvements in areas such as profitability, productivity and new product introduction may often commence their assignment with an exercise. A blank card is given to a group of managers; they are asked to write down the corporate objective(s), then identify the strategies being deployed to achieve the objectives.

As you can imagine, the outcome can be a collection of different objectives; strategies which should be objectives and strategies which are actually tactics. With such an outcome, what is the likelihood of a well defined Supply Chain strategy and the tactics to make it happen?

Of course, not all organisations will have a formal planning process, with financial goals as the driver. Instead, as in a road transport or public warehouse business, there could be a policy of responding to market realities, hopefully with associated financial goals and the means to quickly measure performance.

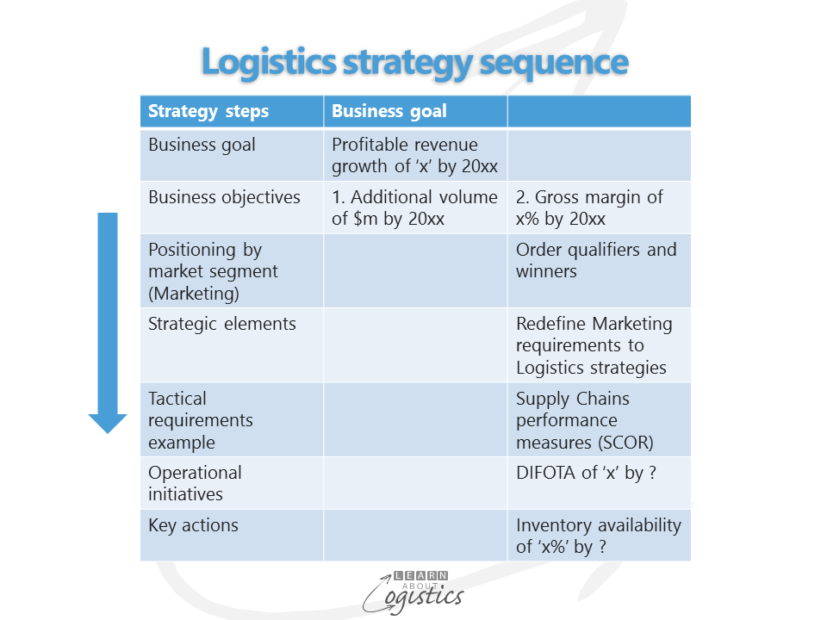

For organisations with a formal planning process, or the desire to have one, there are steps to ensure that a Supply Chain strategy, tactics and action plan is developed that links with Marketing requirements to work for a longer period and deliver superior returns. The Table identifies the most likely steps using the Logistics strategy part of the Supply Chain strategy as an example:

While long term goals and objectives are important, the shorter term (next three to five years) opportunities are of more interest, as this is the time-frame in which the current Supply Chain strategy will operate. The steps for Marketing to develop their strategy are:

- identify the broad market as segments (current and new)

- identify the segments of most potential for the organisation and

- formulate a strategic approach to each segment and often the products sold within that segment

The first step allows Marketing to differentiate the organisation’s approach within one segment of the market against another segment. The third step enables Marketing to place competitive attributes within a segment – how it believes the organisation can win against competitors. These attributes can often be related to non-product aspects such as service, convenience, delivery and information – all to do with Supply Chains. At this step, terms are used to identify what is required from the market segment or product; such as value, cost and service. These and other terms can be combined to describe the approach to a market segment; examples can be ‘perceived value at lower price points’, ‘product quality with high customer service’ or ‘rapid new product introduction and fast delivery’. These statements provide the positioning that Marketing considers will provide the competitive differentiation.

As the objective of Logistics is to provide availability of products and services for customers, the more general requirements of Marketing must be defined from the view of each of the three disciplines that are your organisation’s internal Supply Chains.

Develop your Supply Chain strategy

Using the Logistics strategy as an example, as each market segment has different customer needs, these must be translated into Logistics requirements. This is through using the concept of ‘Order qualifiers and winners’, developed in the early 2000’s to provide the bridge between Marketing and Logistics. Order qualifiers are those factors that a market segment regards as the base performance requirement to be considered for an order. Order winners are the factors that are significant enough to help win orders for products within the market segment.

An organisation can have a situation where it sells a range of products that fall into two or more categories. These are Make to stock (MTS), Assemble to order (ATO), Make to order (MTO) or Engineer to order (ETO) and each needs to differentiate the performance objectives. For example, an MTS item will likely be a standard product with few changes, consistent sales pattern and competitive pricing. Compare this with a MTO item that has non-standard configurations, an irregular sales pattern and a premium price. Many of the input materials could be the same and the products manufactured in the same facility. However, the order qualifiers and winners for each will differ and therefore, so will the Logistics requirements.

The input to generate the Logistics strategy is an accumulation of Logistics requirements for different market segments. The overall Supply Chain strategy incorporates the internal supply chain strategies of Procurement, Material Conversion and Logistics, which are informed by the current and potential structure of the core and extended Supply Chains that interact with your organisation. As Order qualifiers and winners change over time, Marketing and the three Supply Chain disciplines must realign at suitable intervals in response to changing phases through product life cycles and to anticipate industry or market trends. The updated strategy will be enabled by any revision of the core and extended supply chains.

The Supply Chain strategies define the framework of Logistics operations that execute the strategy and therefore the Tactical requirements for achieving the strategic outcomes. The Tactical requirements are then sub-divided into Operational initiatives, which in turn identify the Key actions.

Of course, this does not happen without a champion to drive the process and committed people who understand the ‘what and why’, so the Supply Chain strategy can be seen to be a success and worth the effort.